Gas inlet pipeline protection structure for flat panel type plasma enhanced chemical vapor deposition (PECVD)

A technology for air intake pipes and protective structures, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., which can solve the problem that the coating uniformity of equipment cannot be guaranteed, the reaction gas cannot be controlled, and it takes a lot of manpower and time and other issues, to achieve the effect of low maintenance cost, simple and stable structure, and reduced production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

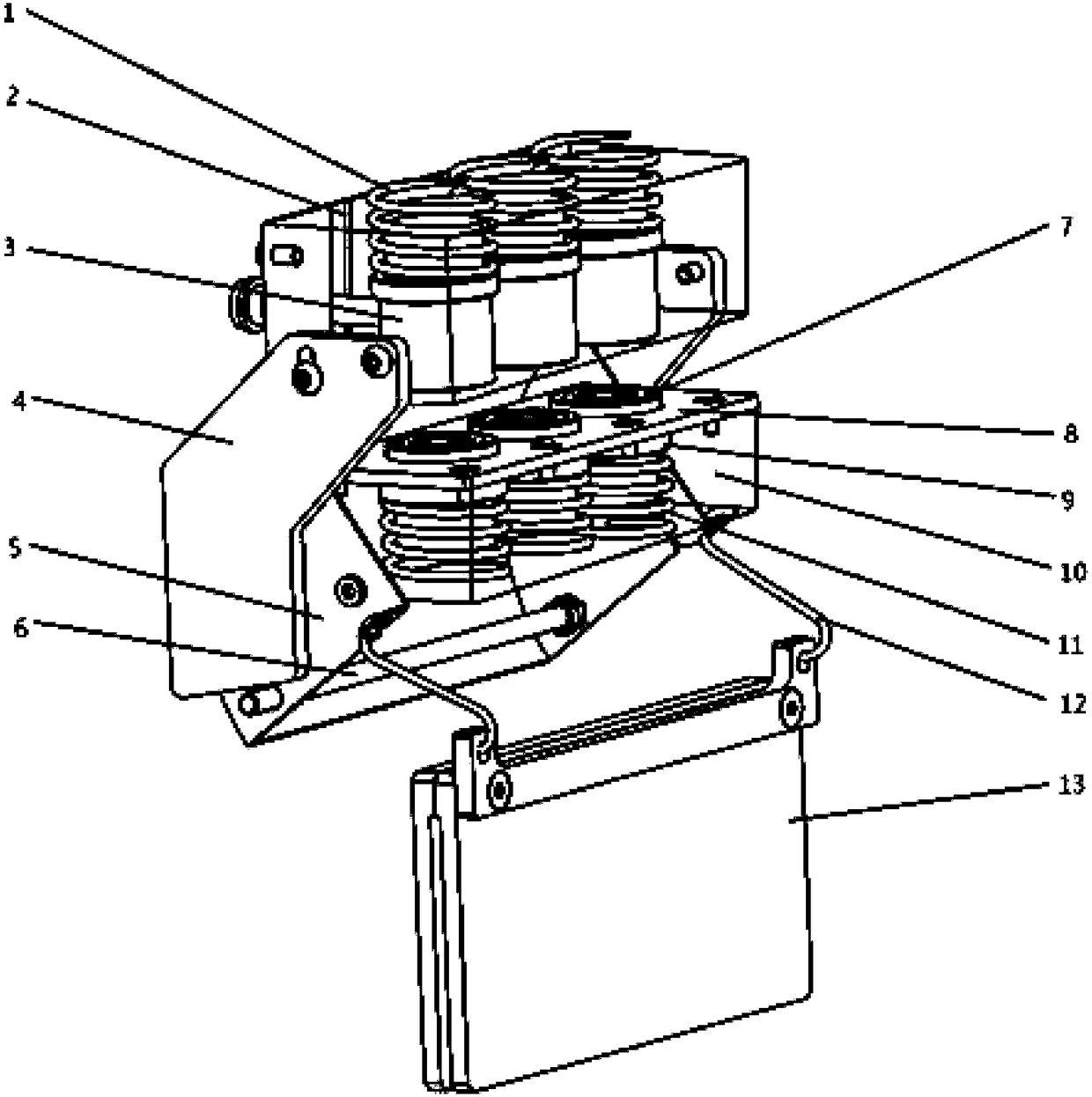

[0024] Such as figure 2 The shown air inlet pipe protection structure for flat PECVD includes an air inlet seat, a dust cover dial 4 , a dust cover 5 , a screw 6 , a hook 12 and a weight 13 .

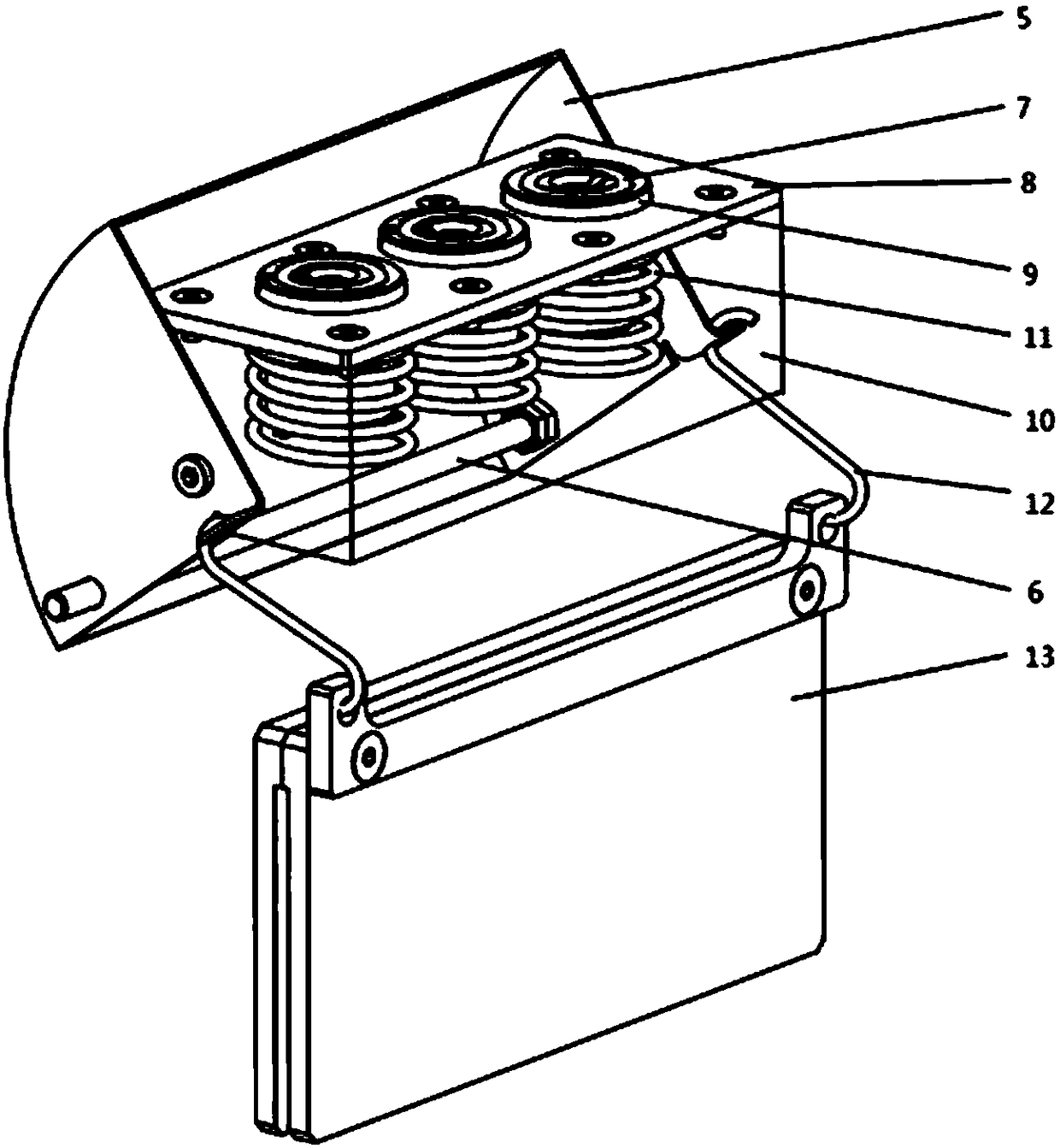

[0025] The air intake seat includes an upper air intake assembly 15 and a lower air intake assembly 17. Because three different special gases need to be introduced, three intake pistons are installed in the air intake seat, but the air intake pistons can also be adjusted according to the air intake needs. The number of gas pistons; each intake piston includes the upper intake piston 3 in the upper intake assembly 15 and the lower intake piston 9 in the lower intake assembly 17, that is, three upper intake pistons 3 and three lower intake pistons are correspondingly provided. Intake piston 9.

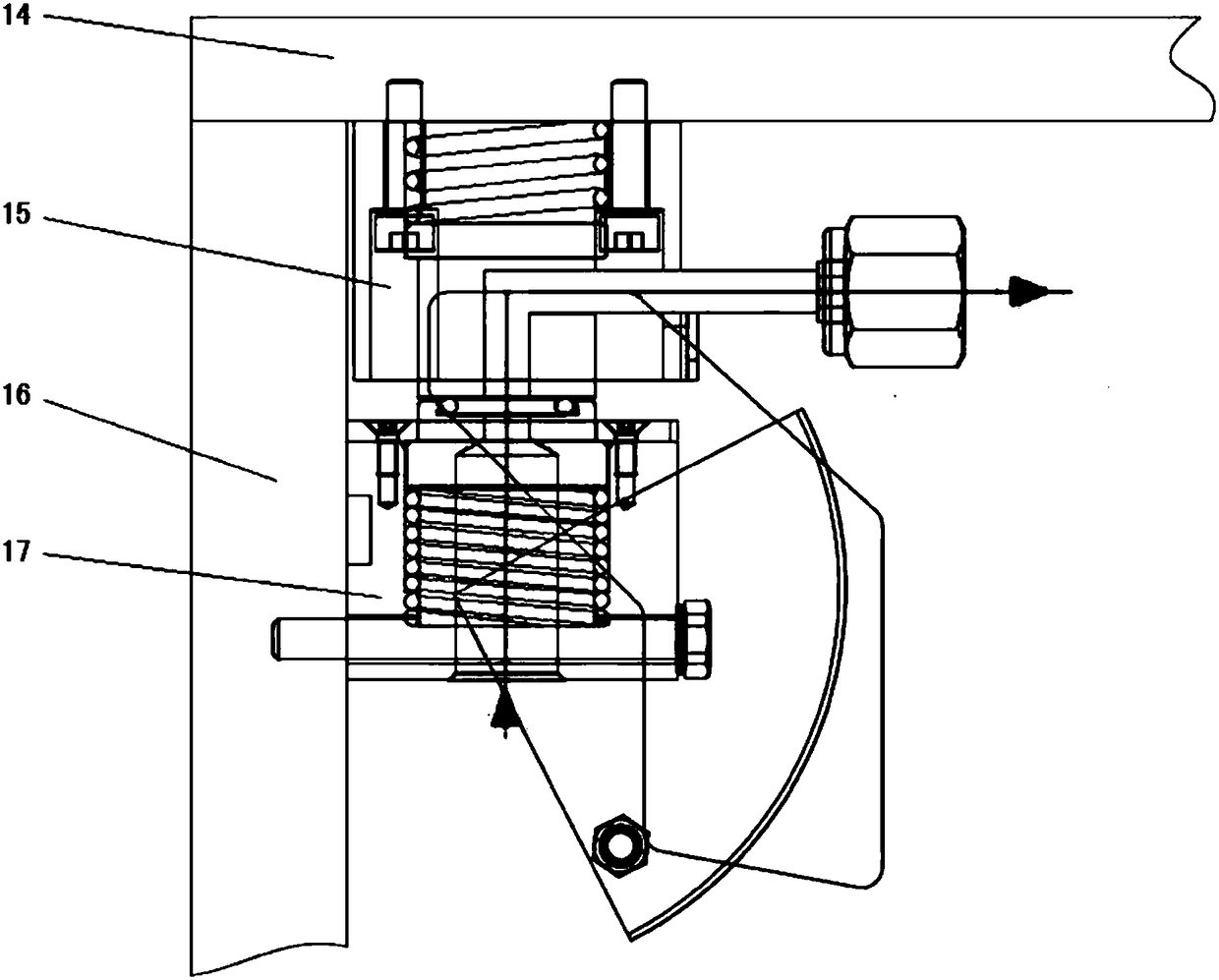

[0026] Such as image 3 The upper intake assembly 15 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com