Gap measuring tool

A technology for measuring tools and gaps, applied in the direction of mechanical gap measurement, etc., to achieve the effect of fast and simple assembly, conforming to operating habits, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0035] The invention discloses a gap measuring tool, which can measure the distance at the gap where a feeler gauge cannot easily reach, and is especially suitable for use when a speed sensor is installed on a flywheel housing of an engine. A through hole is provided on the flywheel housing for installing a rotational speed sensor. The following are specific examples:

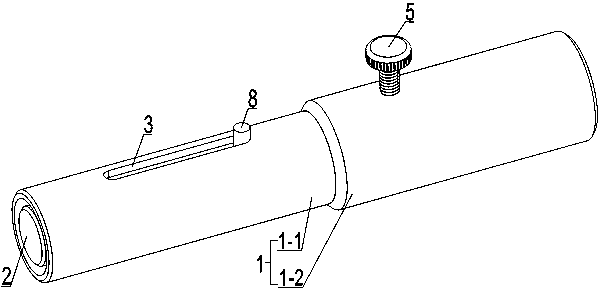

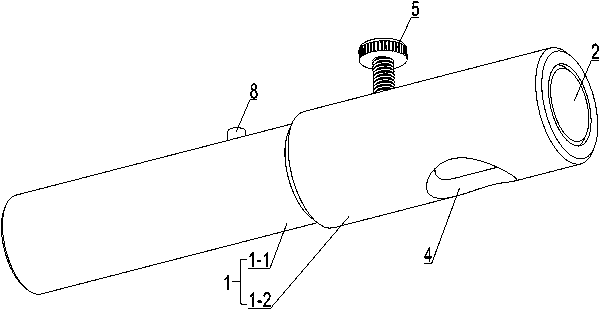

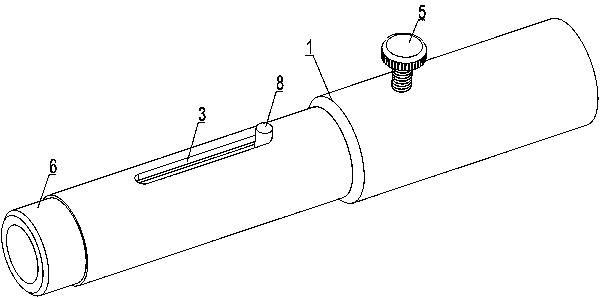

[0036] Gap measurement tool of the present invention, such as figure 1 , figure 2 As shown, it includes a sleeve 1 and a measuring shaft 2 set in the sleeve 1 and having the same length as the sleeve 1 . The measuring shaft 2 can slide along the axis in the sleeve 1. During use, the measuring shaft 2 slides until one end contacts with the speed measuring chainring, thereby converting the gap to be measured between the back of the flywheel housing of the engine and the speed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com