A kind of mulberry leaf picking equipment

A technology of mulberry leaves and equipment, which is applied in the field of mulberry leaf picking equipment, can solve the problems of increasing the difficulty of manual picking, the disorderly extrusion of mulberry leaves, and the less dense mulberry leaves, etc., to achieve the advantages of good handling, good flexibility and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0040] The present invention will be further described below with reference to the accompanying drawings.

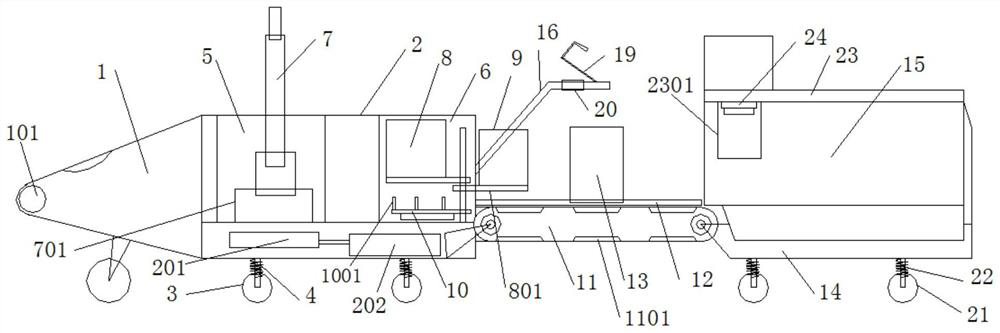

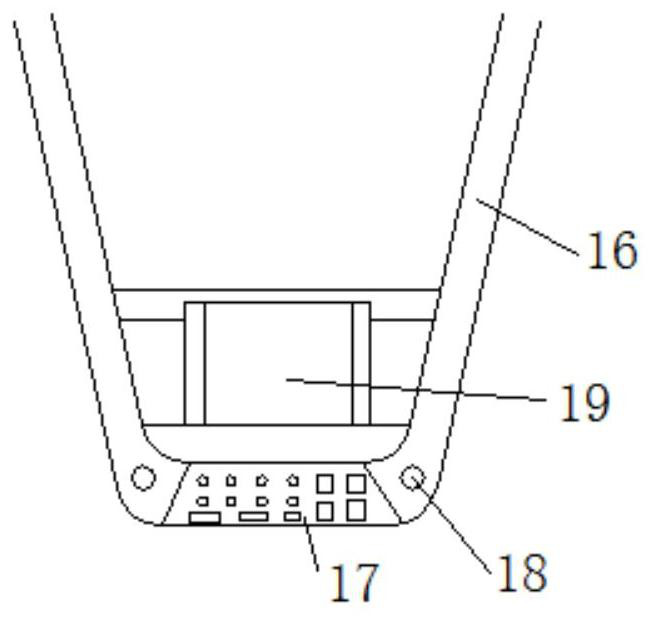

[0041] See Figure 1 - Figure 5 , Figure 8 - Figure 11 As shown, it includes a guide header 1, an operating case 2, a wheel 3, a damper 4, a cartridge one 5, a cartridge two 6, a robot 7, a bracket, a bracket, two 9, a vibrating bracket 10, The conveying member 11, the conveying member bracket 12, the conveying baffle 13, the fixing tow direct, the storage case 15, the push handle 16, the control keyboard 17, the handle 18, the display 19, the processor 20; the guide head 1 is disposed The front end of the case 2; the guiding head is a tapered guiding head, and a plurality of LED lamps 101 are inlaid on the guiding head; the bottom of the guide head 1 is provided with a pressure plate for carrying the weeds on the ground, overwhelming; The bottom portion of the operating case 2 is provided with a number of wheels 3, and the bottom of the wheel and the bottom of the operatin...

specific Embodiment approach 2

[0048] See Figure 1 - Figure 12 As shown, the specific embodiment is different from the specific embodiment in that the lower half of the outer wall of the strip first 8 is provided with a spacer rib 804, and the air between the spacer ribs 804 is mixed with the positioning jaw 1001; Other structures and connection methods are the same as those of the specific embodiments.

specific Embodiment approach 3

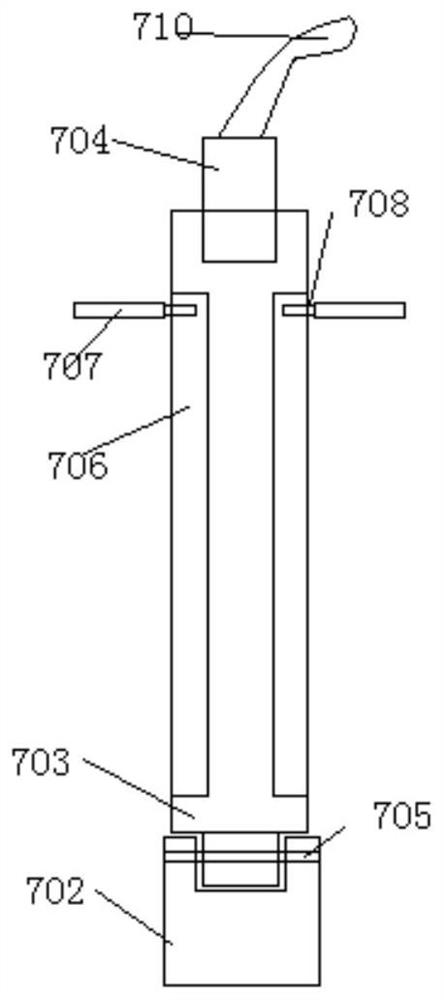

[0050] See Figure 1 - Figure 12 As shown, the specific embodiment is different from the specific embodiment in that the side chopping groove 706 is provided with a circulating chain 711, the tail of the leafy card 707, with the circulating chain 711, and the circulation chain 711. The leafy claw 707 can be moved up and down, and several sub-claws can be mounted on the circulation chain 711; other structures are the same as those of the specific embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com