Compressor and control method and controller thereof

A control method and compressor technology, applied in the field of control, can solve the problems of low energy efficiency and service life of compressors, and achieve the effect of reducing the duration and increasing the compression rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

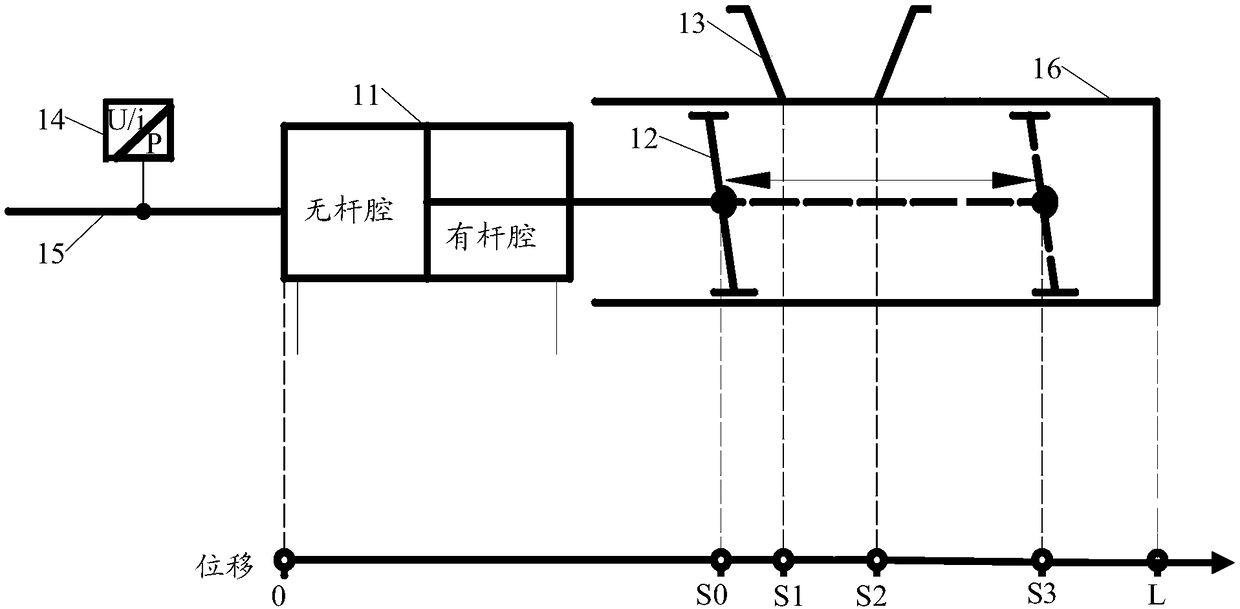

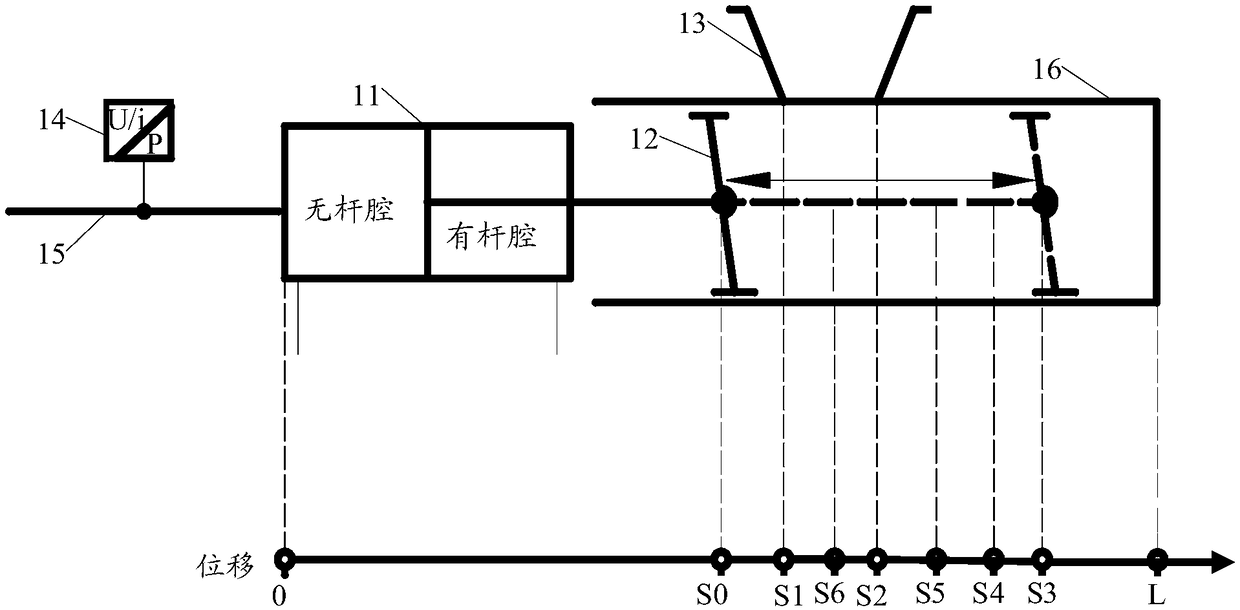

[0033] figure 1 A schematic diagram of the working principle of a garbage compactor in the prior art is given, as figure 1As shown, the garbage compactor can include a push head 12, a hydraulic cylinder 11 suitable for driving the push head 12, a hopper 13, a main pressure oil channel 15 and a pressure sensor suitable for detecting the pressure in the main pressure oil channel 15. sensor 14. Wherein: the hydraulic cylinder 11 includes a rod chamber and a rodless chamber, and the rod chamber is hinged to the push head 12 . The push head 12 and the hydraulic cylinder 11 are arranged in the compression box 16 . The main pressure oil channel 15 is coupled with the hydraulic cylinder 11 and is suitable for supplying oil to the hydraulic cylinder 11 , and the internal pressures of the two are the same.

[0034] Moreover, the position corresponding to one side of the rodless chamber of the hydraulic cylinder 11 is taken as the origin, and all the positions or displacements describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com