Optical measurement method and device with control points

An optical measurement and control point technology, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of difficult layout, low efficiency, and heavy workload of optical measurement mark layout, and achieve high precision, high efficiency, and overcome work A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: An example of an optical measurement method using control points

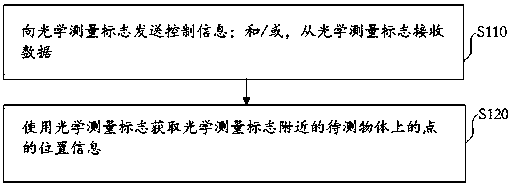

[0035] See figure 1 As shown, an embodiment of an optical measurement method using control points provided by the present invention includes:

[0036] Step S110, sending control information to the optical measurement sign; and / or, receiving data from the optical measurement sign;

[0037] In step S120, the optical measurement mark is used to obtain position information of points on the object to be measured near the optical measurement mark.

[0038] The optical measurement mark serves as a measurement control point.

[0039] Generally, four or more measurement control points are arranged in a scene covered by an optical imaging picture. Typically, four to sixteen measurement control points are arranged. If there are more measurement control points, the measurement error is small.

[0040] The optical measurement indicator, receiving the control information through a wired channel or a wireless channel,...

Embodiment 2

[0183] The second embodiment, an example of an optical measurement device using control points

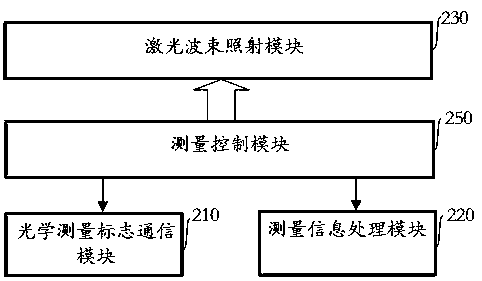

[0184] See figure 2 As shown, an embodiment of an optical measurement device using control points provided by the present invention includes:

[0185] Optical measurement sign communication module 210 and measurement information processing module 220; among them,

[0186] The optical measurement sign communication module 210 is used for sending control information to the optical measurement sign; and / or, receiving data from the optical measurement sign, including a wireless or wired transmission sub-module;

[0187] The measurement information processing module 220 is configured to use the optical measurement mark to obtain position information of points on the object to be measured near the optical measurement mark, and includes a data processing sub-module.

[0188] The device given in this embodiment further includes a laser beam irradiation module 230 and a measurement control module 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com