Gear internal diameter measurement mechanism based on self-centering and measurement method thereof

A measuring mechanism and self-centering technology, used in measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of poor adaptability of measuring and positioning tooling, measuring tooling affecting measurement accuracy, slow measurement rhythm, etc. Objective, low cost, reasonable design and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

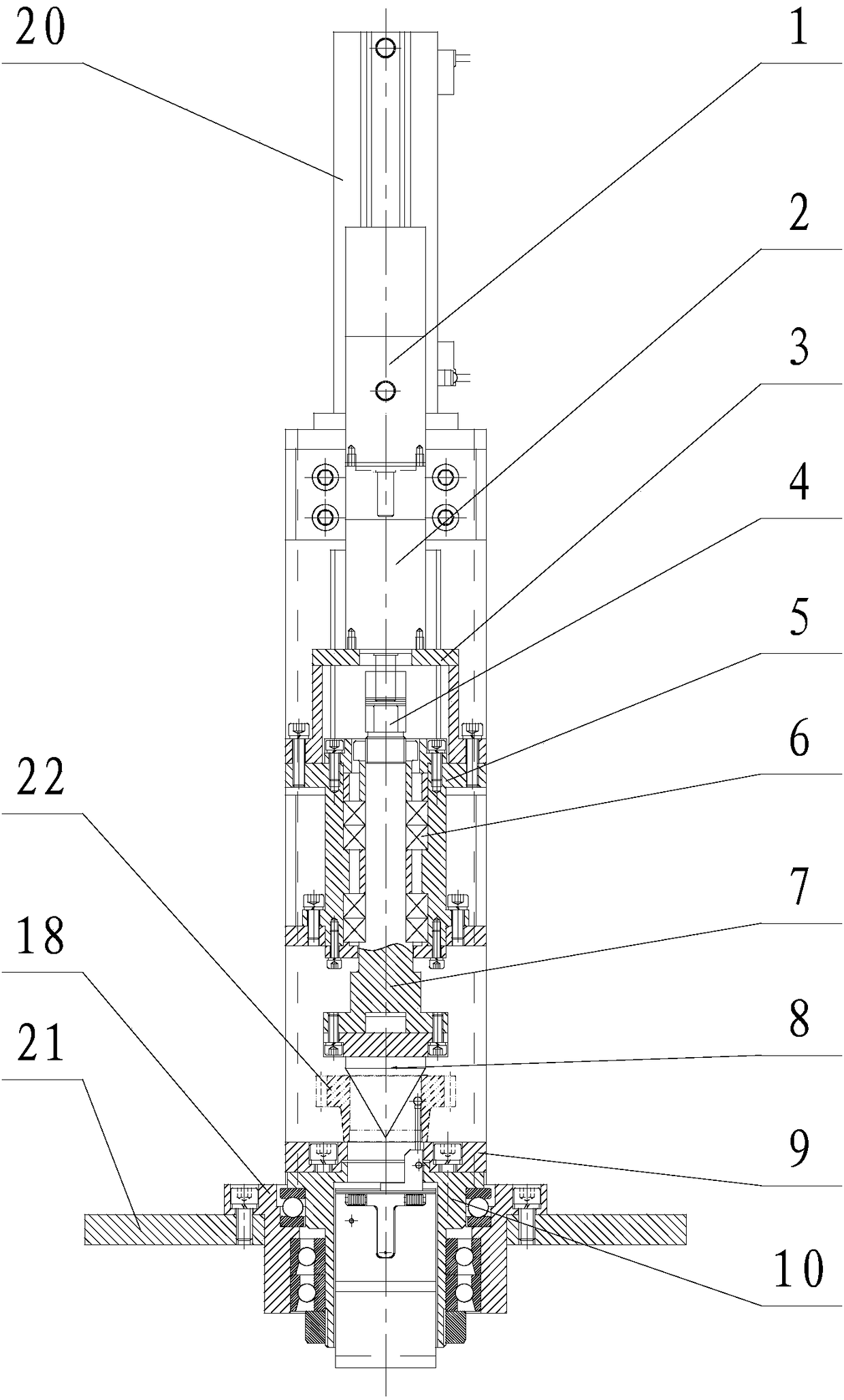

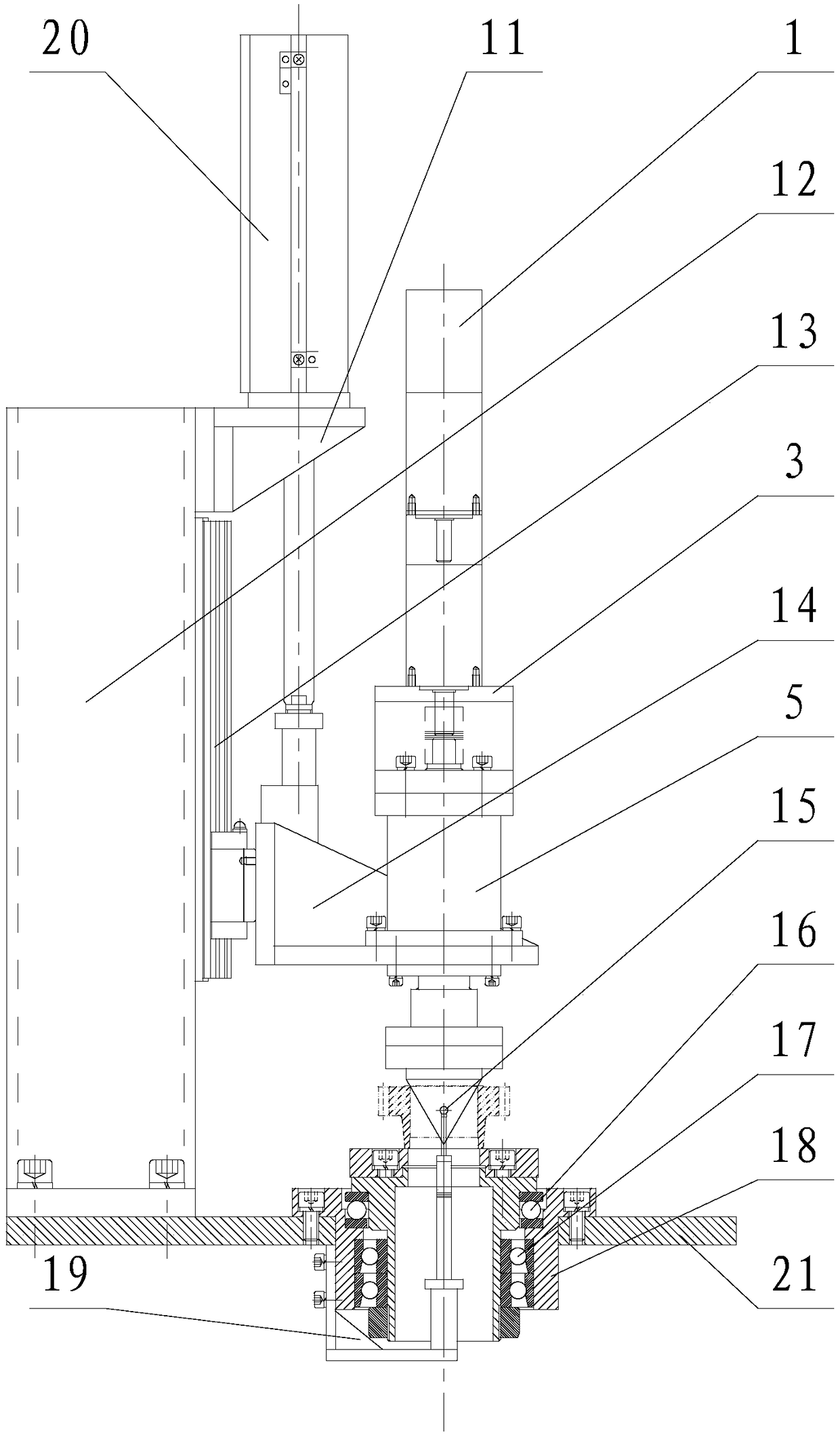

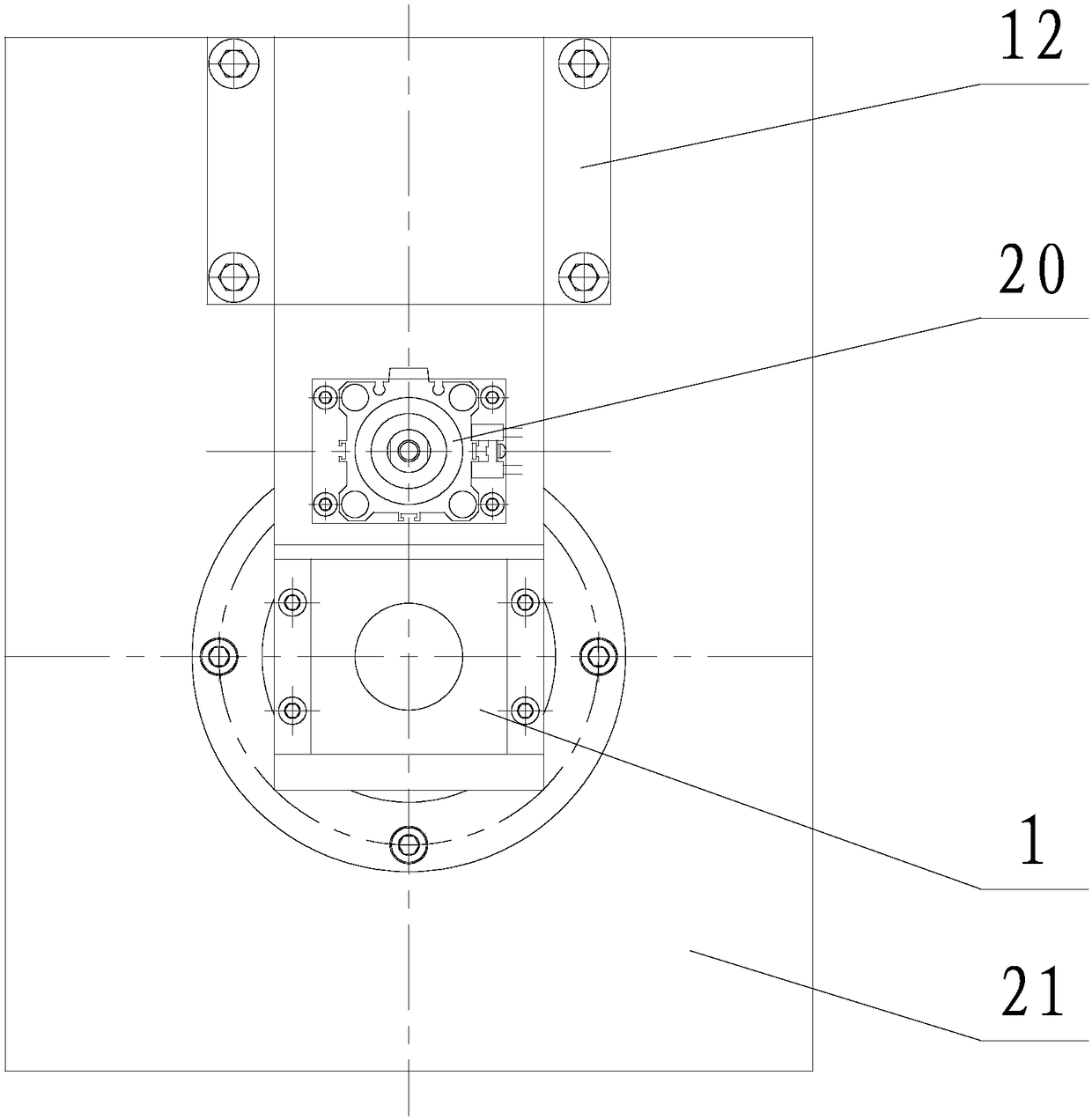

[0031] Such as Figure 1~3 As shown, the measuring mechanism of the present invention includes a centering driving part, a passive rotating measuring part and a main body part of the equipment, wherein the centering driving part includes a power source, a fixed bracket 3, a rotating fixed sleeve 5, a rotating shaft 7 and a positioning tip 8, The passive rotation measurement part includes a rotating disk 9, a rotating seat 10, a block-type displacement sensor 15 and a passive rotating sleeve 18. The main body of the equipment includes a fuselage 12, a cylinder 20, a cylinder support 11, a lifting slide 14, a linear guide rail 13 and Platen 21 .

[0032] The fuselage 12 and the passive rotating sleeve 18 are respectively fixed on the platen 21 , the cylinder 20 is fixed on the top of the fuselage 12 through the cylinder bracket 11 , and the piston of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com