Cultivating liquid storage structure of biosensor

A biosensor and liquid storage technology, applied in the field of cultivation liquid storage structure, can solve the problems of complicated operation and high personnel requirements, and achieve the effects of convenient replacement, complete replacement and rapid liquid discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

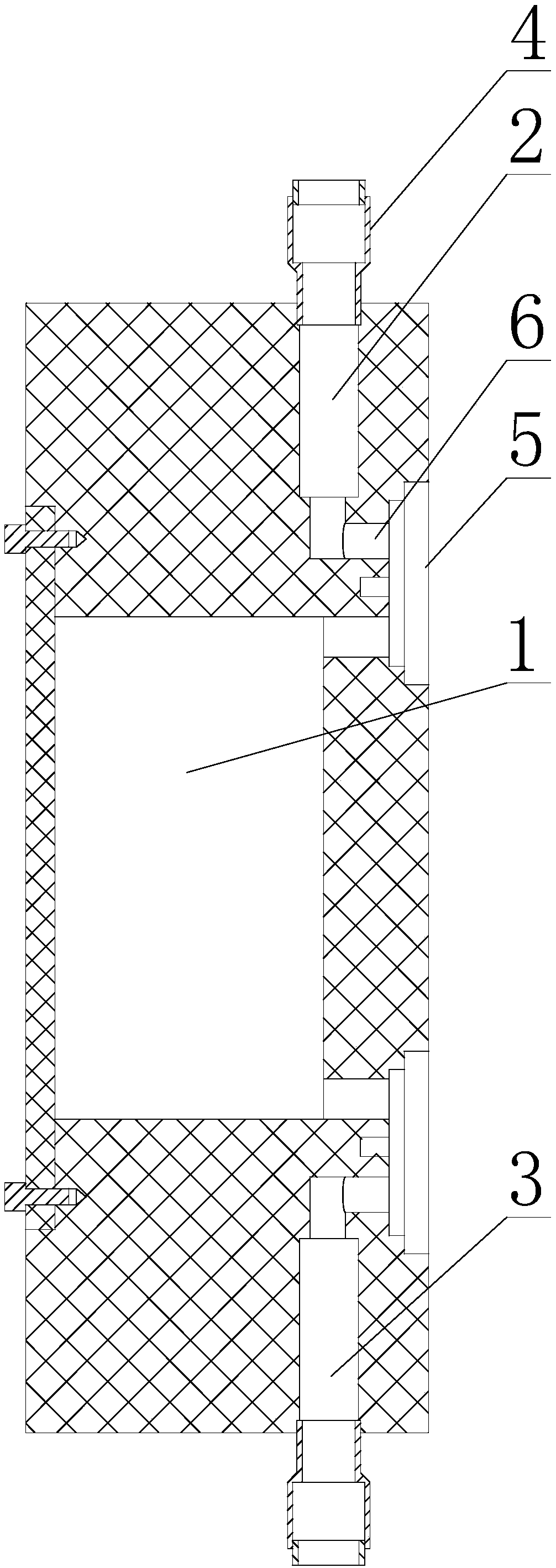

[0023] like figure 1 As shown, the cultivation fluid storage structure in the biosensor includes a liquid storage structure body and a liquid storage chamber 1 arranged on the liquid storage structure body, and the liquid storage chamber 1 is a cavity enclosed in the liquid storage structure body;

[0024] It also includes the first pipeline 2 and the second pipeline 3 arranged on the liquid storage structure body, and two accommodating chambers 5 arranged on the side of the liquid storage structure body, and the accommodating chambers 5 are all steps with a stepped surface A hole-shaped blind hole, and the end with a larger cross-sectional size of each accommodation cavity 5 is the outer end, and the hole depth direction of each accommodation cavity 5 is located in the horizontal direction;

[0025] In the horizontal direction, one of the accommodation chambers 5 is located outside the top end of the liquid storage chamber 1, and the other accommodation chamber 5 is located o...

Embodiment 2

[0031] like figure 1 As shown, this embodiment is further limited on the basis of Embodiment 1: the top end of the first pipeline 2 and the bottom end of the second pipeline 3 are both equipped with quick connectors 4 for air source pipes. In this solution, by setting the gas source pipe quick connector 4 on the two pipelines, when in use, the corresponding fluid pipe adopts the hose method, so that the gas source pipe and the upper gas source pipe can be quickly removed when the liquid storage chamber 1 enters the liquid. The connection of joint 4 is to realize pressure equalization and complete the connection between the cultivation liquid pipe and the quick joint 4 of the lower air source pipe to facilitate liquid intake; It is used to introduce purge gas into the liquid storage chamber 1, and replace the hose on the quick connector 4 of the lower gas source pipe with a waste liquid pipe for waste liquid diversion.

[0032]In order to make this solution adaptable to hoses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com