Bait casting machine for aquaculture

An aquaculture and feeding machine technology, which is applied in application, fish farming, climate change adaptation, etc., can solve the problems of low feeding efficiency and insufficient uniform feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

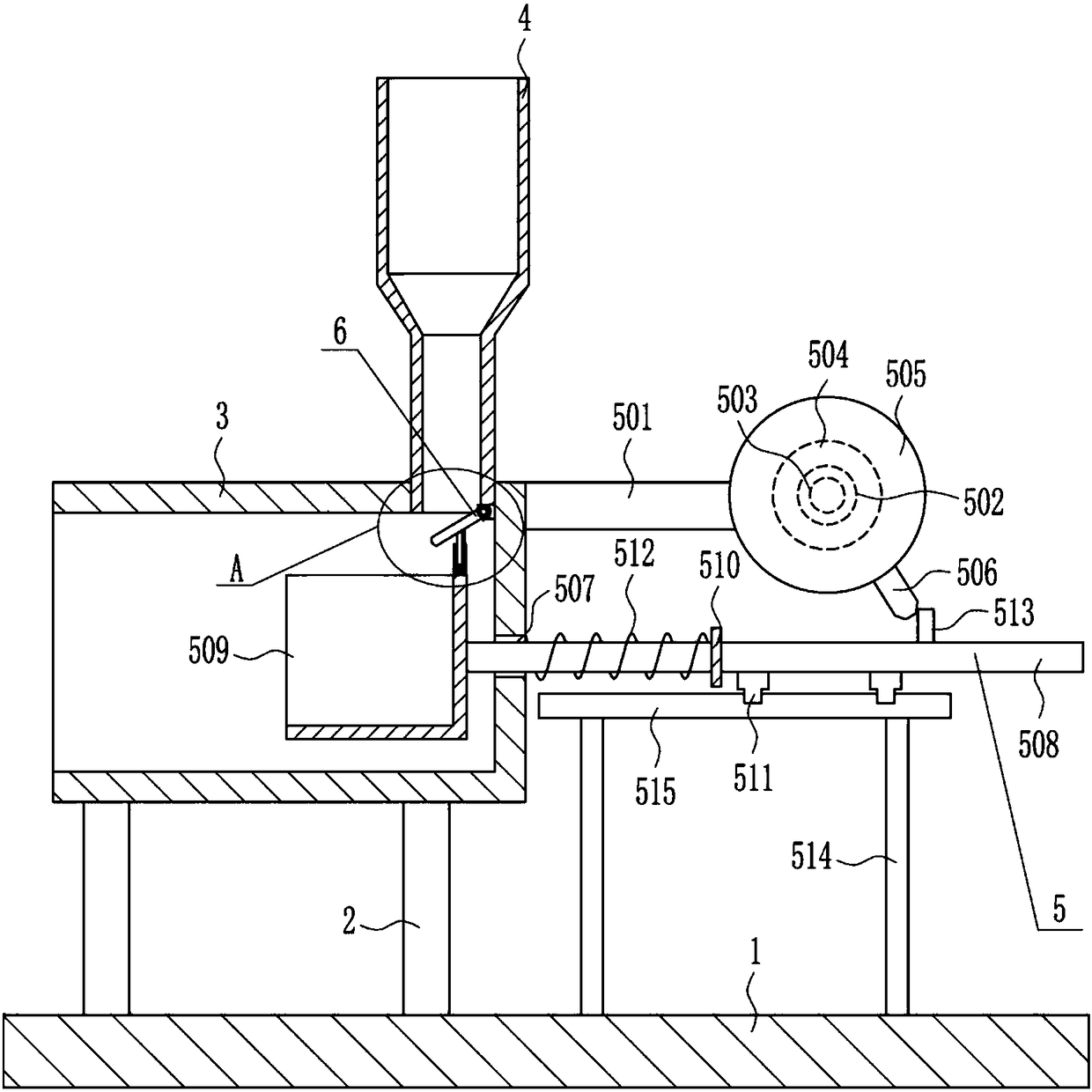

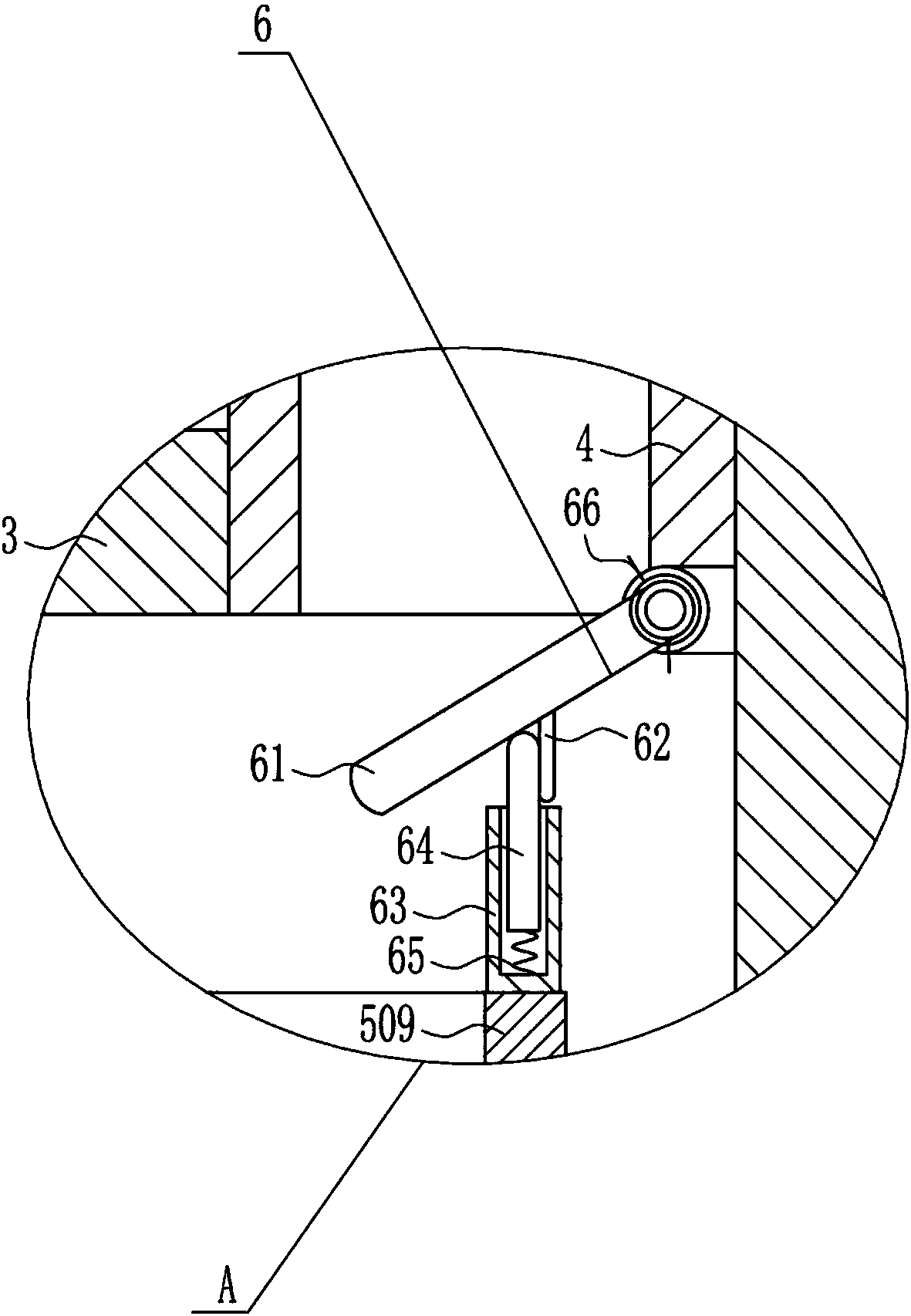

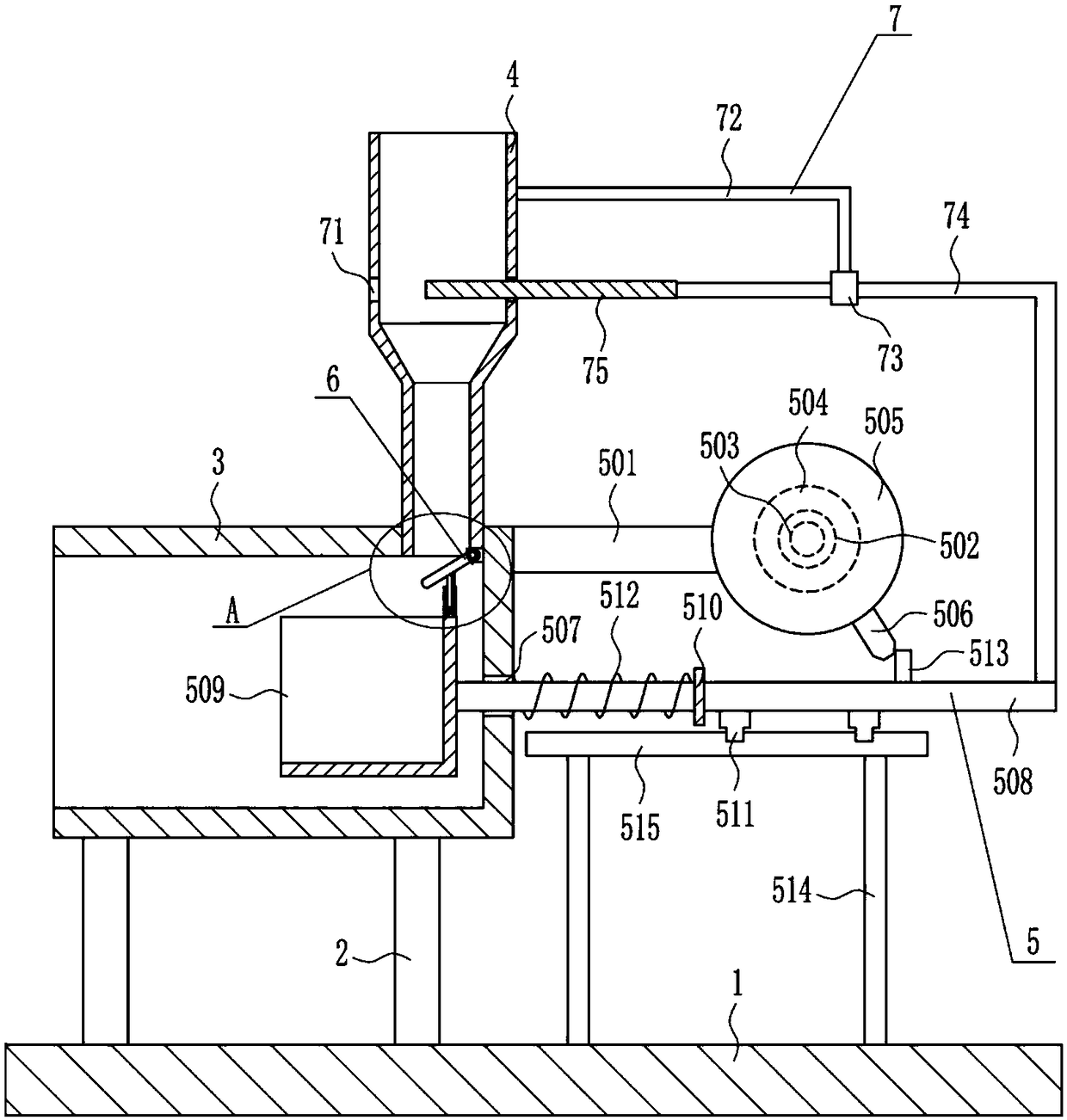

[0029] A bait feeding machine for aquaculture, such as Figure 1-4 As shown, it includes a bottom plate 1, a first pole 2, a frame body 3, a hopper 4, a feeding device 5 and a feeding device 6, and four first poles 2 are installed on the left side of the top of the bottom plate 1. The first pole 2. A frame body 3 is installed on the top, and the left side of the frame body 3 is open. A lower hopper 4 is installed on the right side of the top of the frame body 3. The lower hopper 4 communicates with the frame body 3. A feeding device 5 is installed on the top right of the bottom plate 1. The feeding part of the feeding device 5 is located in the frame body 3 , and the top right of the frame body 3 is provided with a feeding device 6 .

Embodiment 2

[0031] A bait feeding machine for aquaculture, such as Figure 1-4 As shown, it includes a bottom plate 1, a first pole 2, a frame body 3, a hopper 4, a feeding device 5 and a feeding device 6, and four first poles 2 are installed on the left side of the top of the bottom plate 1. The first pole 2. A frame body 3 is installed on the top, and the left side of the frame body 3 is open. A lower hopper 4 is installed on the right side of the top of the frame body 3. The lower hopper 4 communicates with the frame body 3. A feeding device 5 is installed on the top right of the bottom plate 1. The feeding part of the feeding device 5 is located in the frame body 3 , and the top right of the frame body 3 is provided with a feeding device 6 .

[0032] The feeding device 5 includes a support plate 501, a first bearing seat 502, a first rotating shaft 503, a first motor 504, a turntable 505, a first contact tooth 506, a slide bar 508, a discharge frame 509, a limit plate 510, a first Sl...

Embodiment 3

[0034] A bait feeding machine for aquaculture, such as Figure 1-4 As shown, it includes a bottom plate 1, a first pole 2, a frame body 3, a hopper 4, a feeding device 5 and a feeding device 6, and four first poles 2 are installed on the left side of the top of the bottom plate 1. The first pole 2. A frame body 3 is installed on the top, and the left side of the frame body 3 is open. A lower hopper 4 is installed on the right side of the top of the frame body 3. The lower hopper 4 communicates with the frame body 3. A feeding device 5 is installed on the top right of the bottom plate 1. The feeding part of the feeding device 5 is located in the frame body 3 , and the top right of the frame body 3 is provided with a feeding device 6 .

[0035] The feeding device 5 includes a support plate 501, a first bearing seat 502, a first rotating shaft 503, a first motor 504, a turntable 505, a first contact tooth 506, a slide bar 508, a discharge frame 509, a limit plate 510, a first Sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com