Soymilk machine

A soymilk machine and pulping technology, applied in kitchen utensils, home utensils, applications, etc., can solve the problems of low disturbance degree and low crushing efficiency, and achieve the effect of high disturbance degree, high pulping efficiency, and improved crushing degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further detailed explanation through specific implementation mode below:

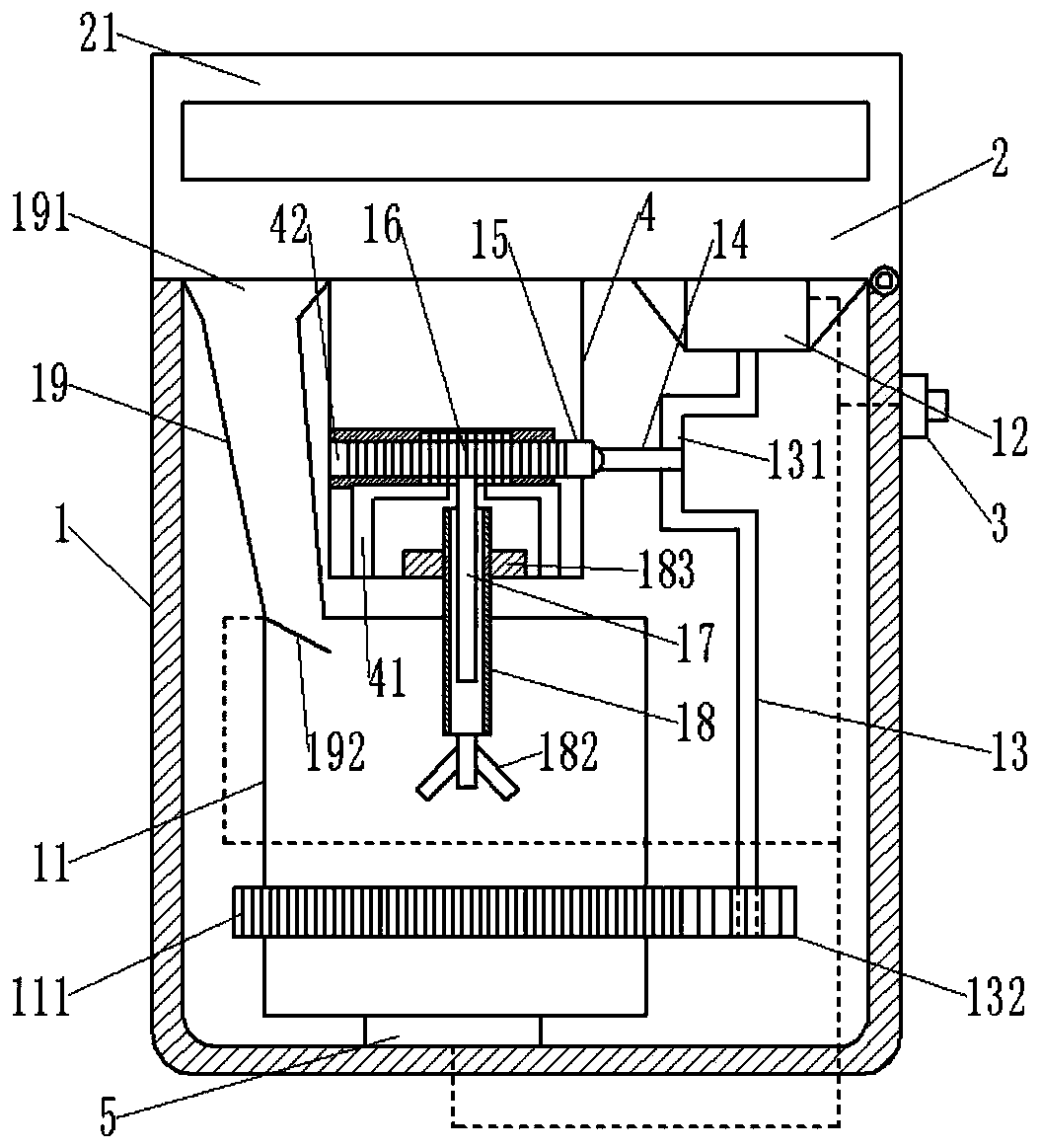

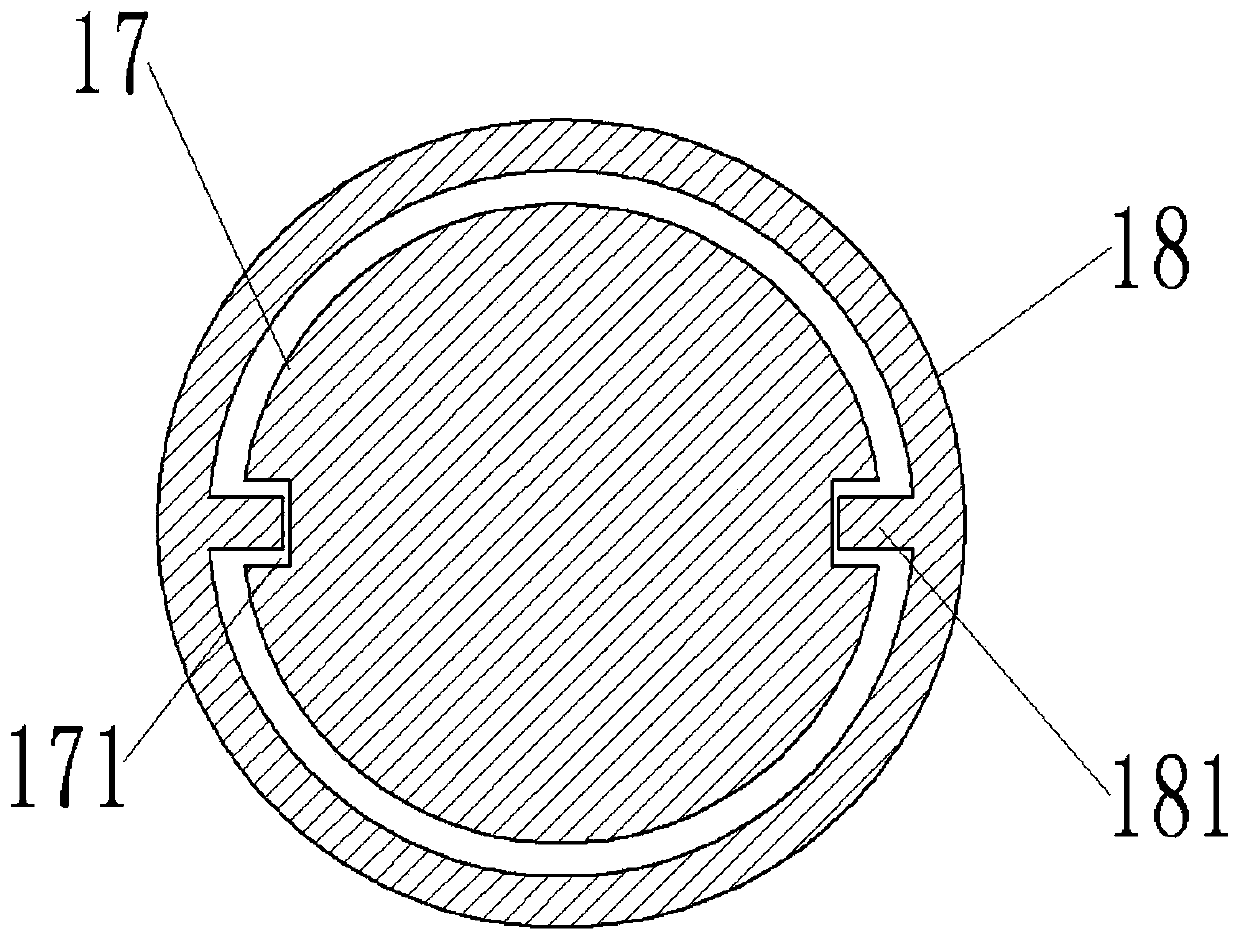

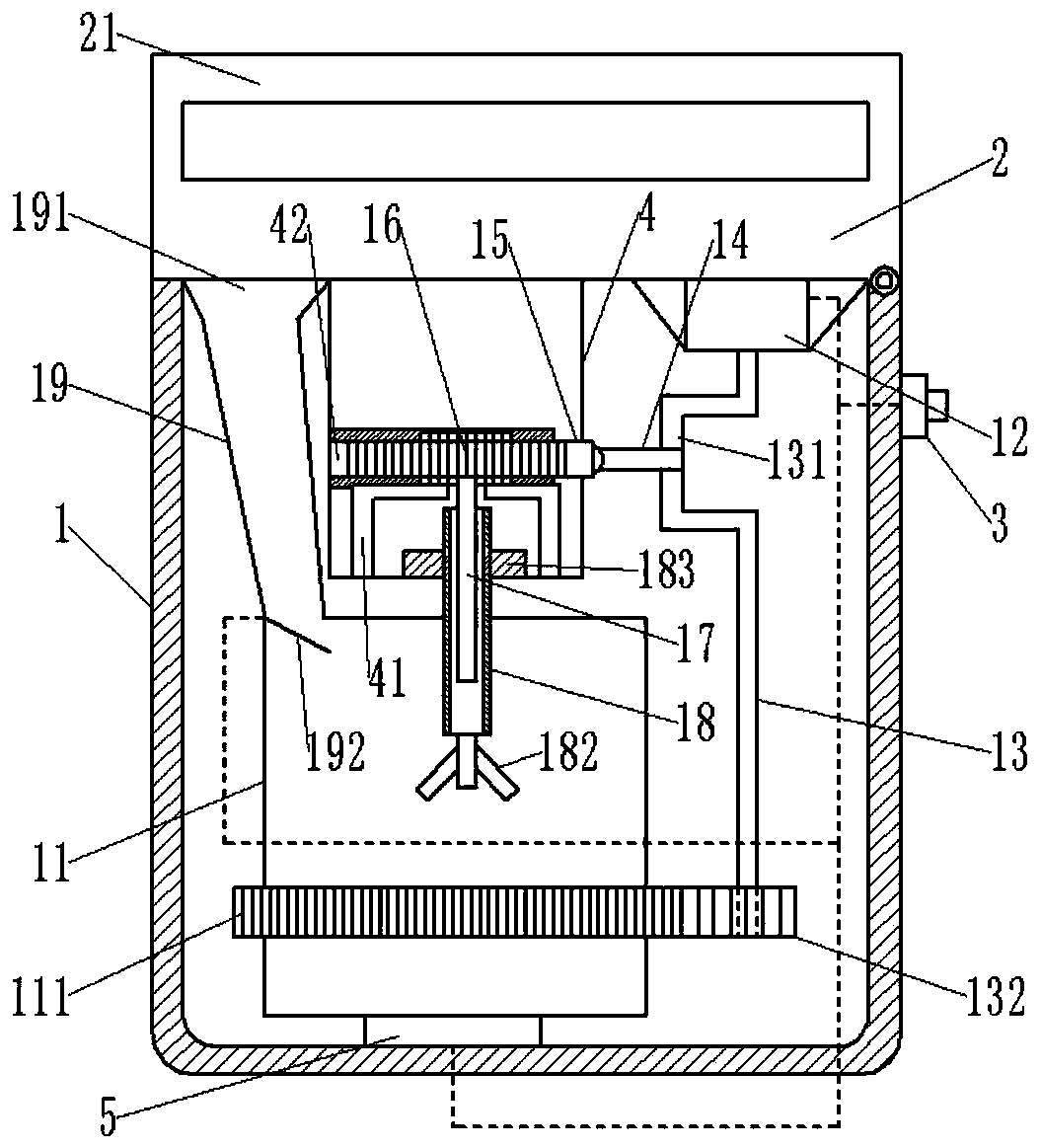

[0015] The reference signs in the accompanying drawings of the description include: cylinder 1, pulping cylinder 11, ring gear 111, motor 12, crankshaft 13, connecting rod journal 131, second gear 132, connecting rod 14, rack 15, first Gear 16, rotating shaft 17, first chute 171, screw rod 18, bump 181, blade 182, nut 183, feeding pipe 19, feeding port 191, valve 192, cover body 2, handle 21, control switch 3, support Frame 4, support seat 41, second chute 42, electric heater 5.

[0016] The embodiment is basically as attached figure 1 As shown: a soymilk machine, including a cylinder 1 and a cover 2 hinged to the upper end of the cylinder 1, the cylinder 1 is provided with a pulping cylinder 11 and a crushing mechanism, and the cover 2 is provided with a handle 21, the crushing The mechanism includes a screw rod 18, a first gear 16, a motor 12, a crankshaft 13 connected to the output end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com