Self-cleaning filter of scraper knife

A self-cleaning filter and scraper technology, applied in the direction of fixed filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems of impurities sticking, unable to completely clear impurities, etc., and achieve the effect of removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

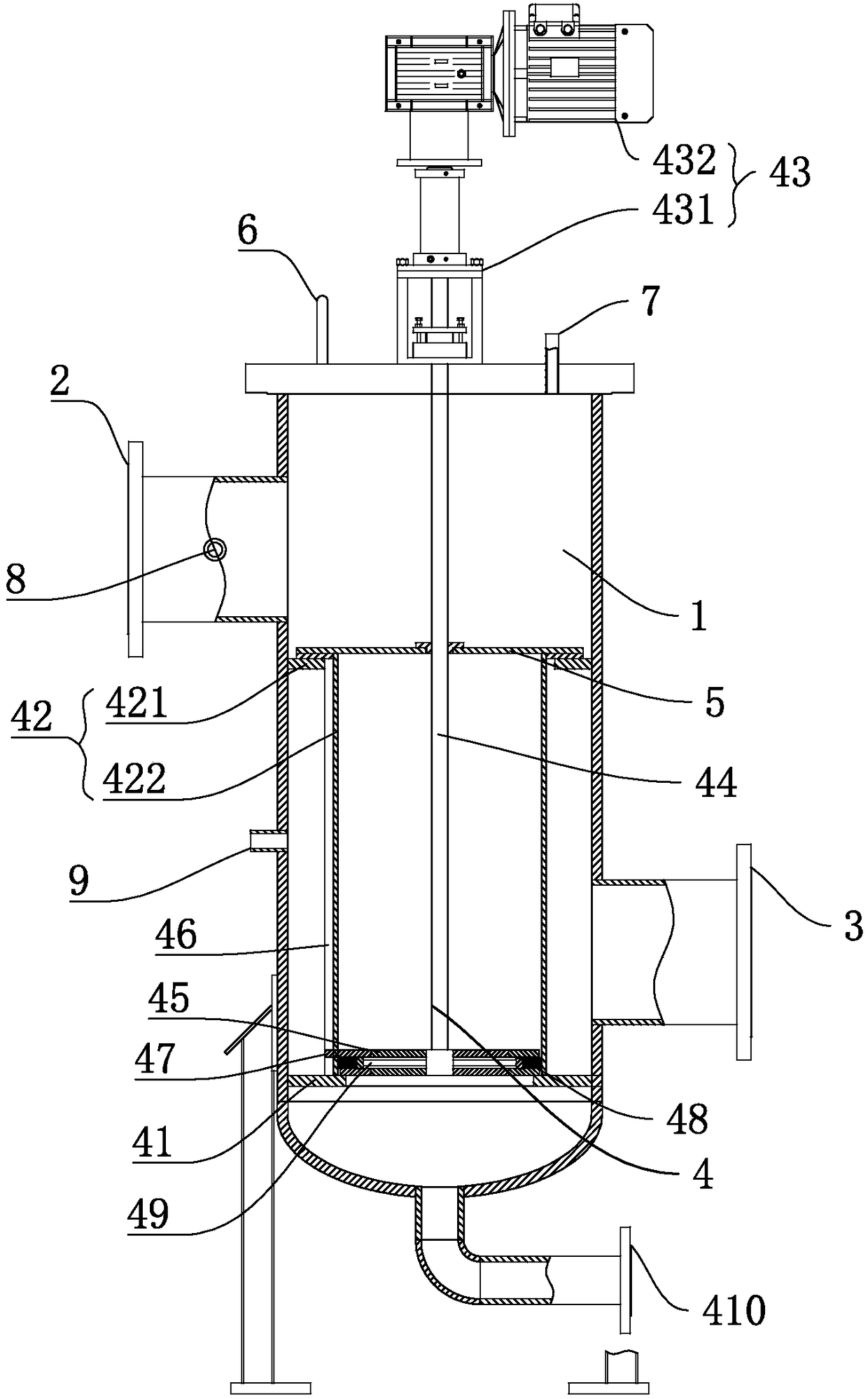

[0025] Embodiment 1: a kind of scraper self-cleaning filter, as figure 1 As shown, including the tank body 1, the top side of the tank body 1 is provided with an inlet pipe 2 communicating with the tank body 1, the bottom side of the tank body 1 is provided with an outlet pipe 3, and the inlet pipe 2 is provided with a first differential pressure gauge interface 8. A second differential pressure gauge interface 9 is provided on the outer wall of the middle part of the tank body 1, and a lifting lug 6 is provided on one side of the top of the tank body 1, and an emptying pipe 7 communicating with the tank body 1 is provided on the other side. The tank body 1 is provided with a scraping device 4, the scraping device 4 includes a base plate 41 located on the inner wall of the tank body 1 below the outlet pipe 3, and a filter device 42 fixed on the base plate 41, and the filter device 42 includes a filter device located under the inlet pipe 2. The inner wall of the tank body 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com