Glass lace grinding method

A lace and glass technology, applied in the direction of grinding/polishing equipment, grinding machines, machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of low added value and single product form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

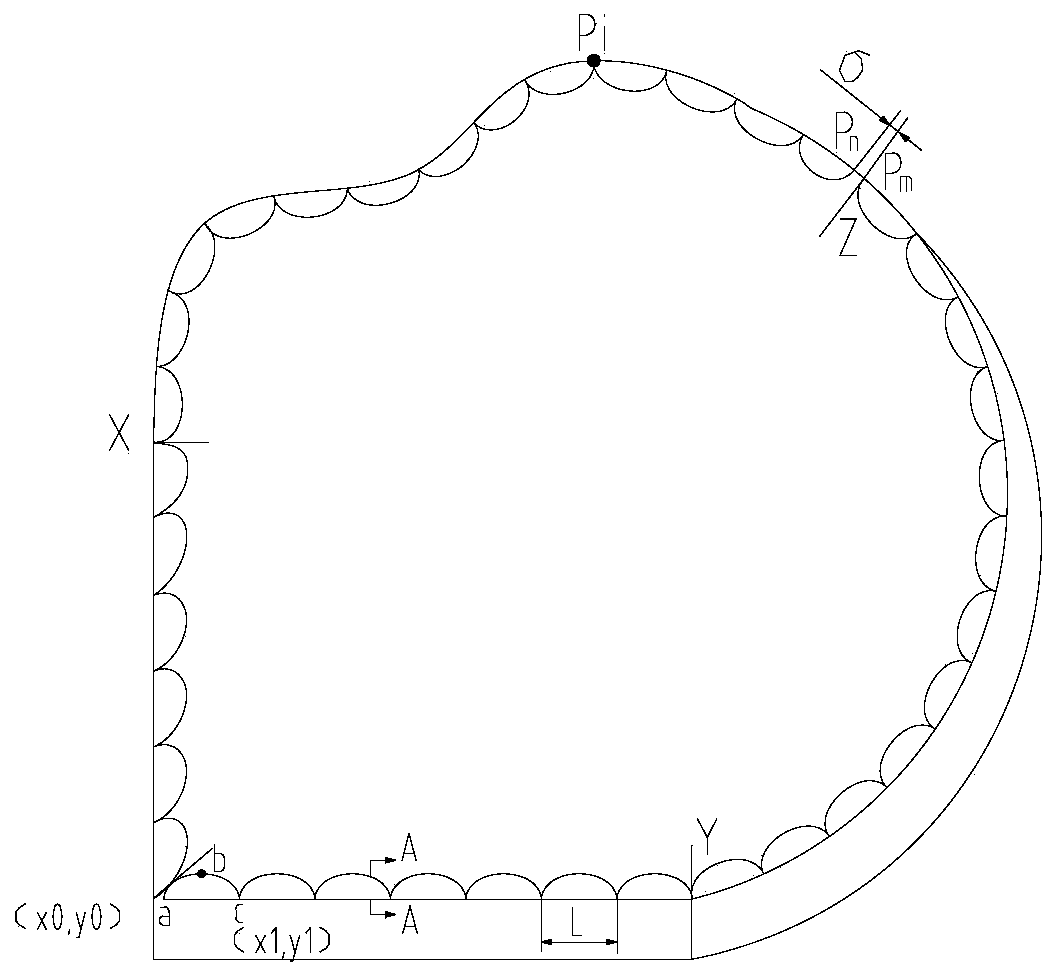

[0097] In the glass lace grinding method, the realization of the method is based on a four-axis linkage glass beveling equipment, wherein the four axes are: X axis, Z axis, C1 axis and C2 axis; specifically, the X axis can realize The tool can move forward and backward; the Z axis can realize the up and down direction movement of the tool; the C1 axis can realize the rotary feeding movement of the glass; the C2 axis can realize the rotation movement of the grinding wheel around the Z axis, and always maintain a tangent state with the glass contour.

[0098] Wherein, in the glass lace grinding method, the processing tool used is a grinding wheel, such as a diamond grinding wheel.

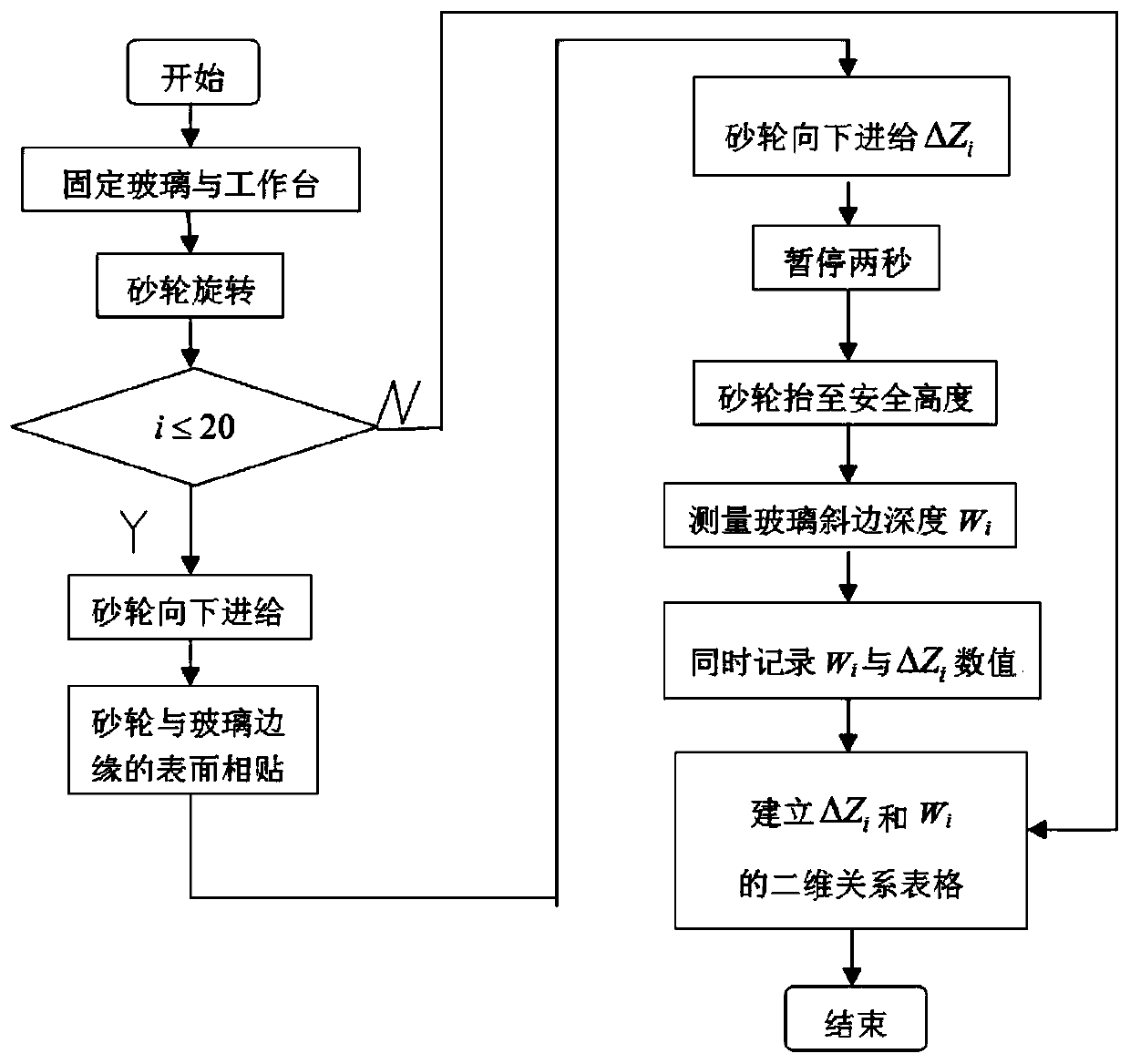

[0099] In some embodiments, when the glass lace grinding method is used for grinding, the following preparatory work needs to be done before grinding.

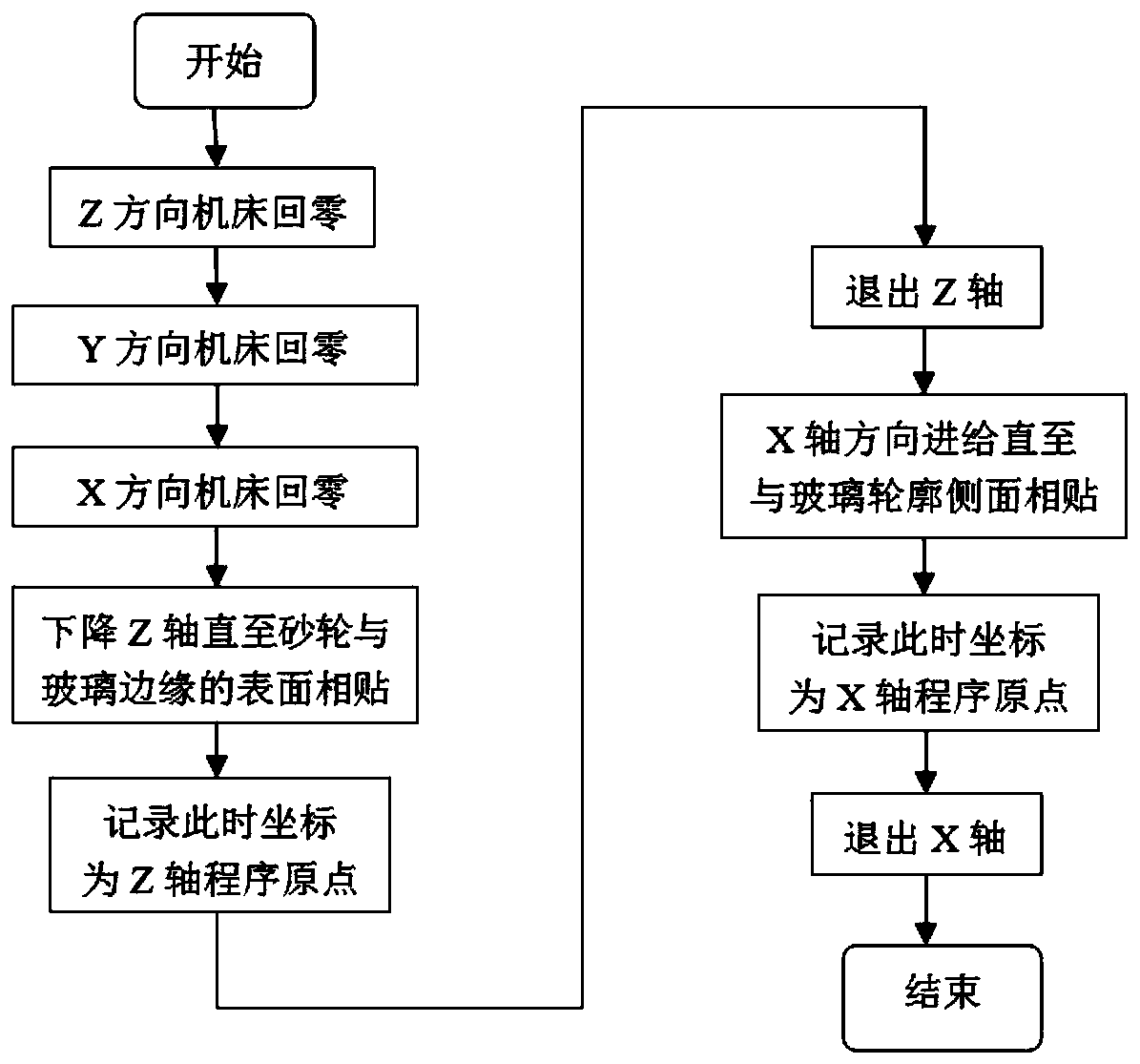

[0100] (1) Tool setting. The main purpose of tool setting is to establish the position of the tool in X axis, Z axis, C 1 Axis and C 2 The relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com