Vertical take-off and landing aircraft with layouts of tilting ducts and connecting wings

A technology of vertical take-off and landing and connecting wings, applied in the field of unmanned aerial vehicles, it can solve the problems of inability to trim the pitching moment, the aircraft cannot maintain the vertical attitude, etc. Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

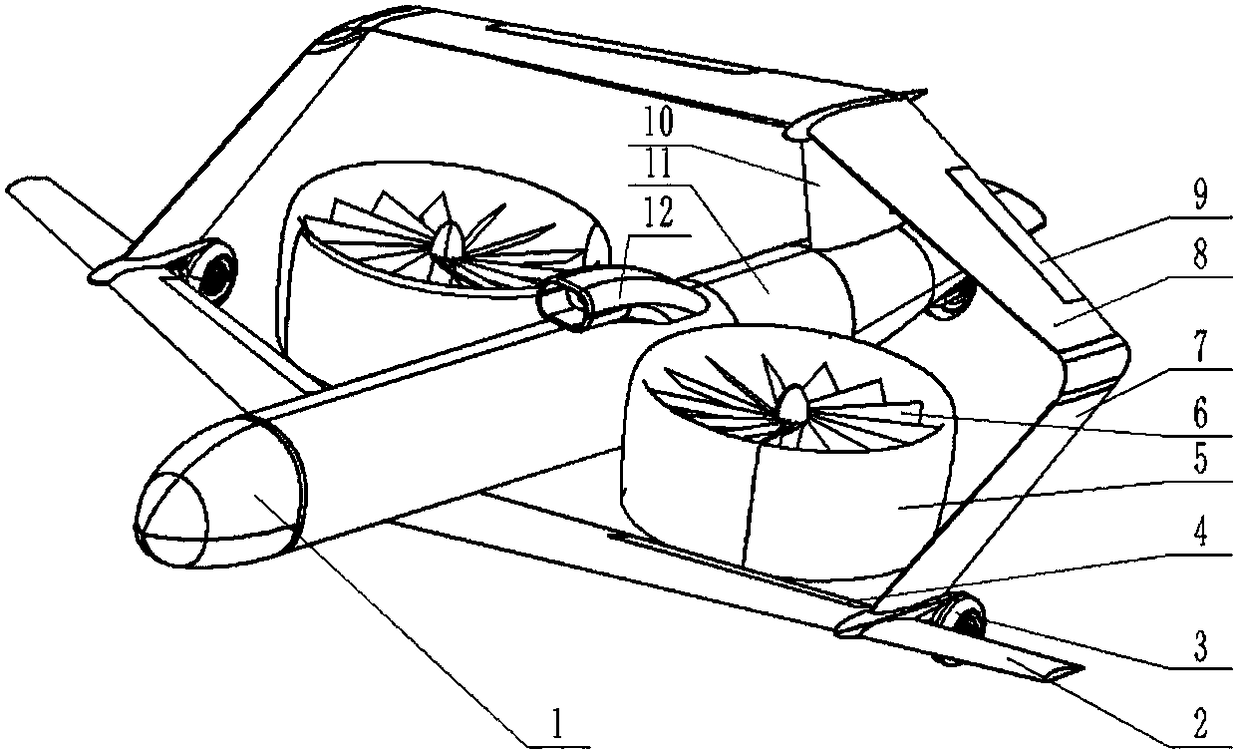

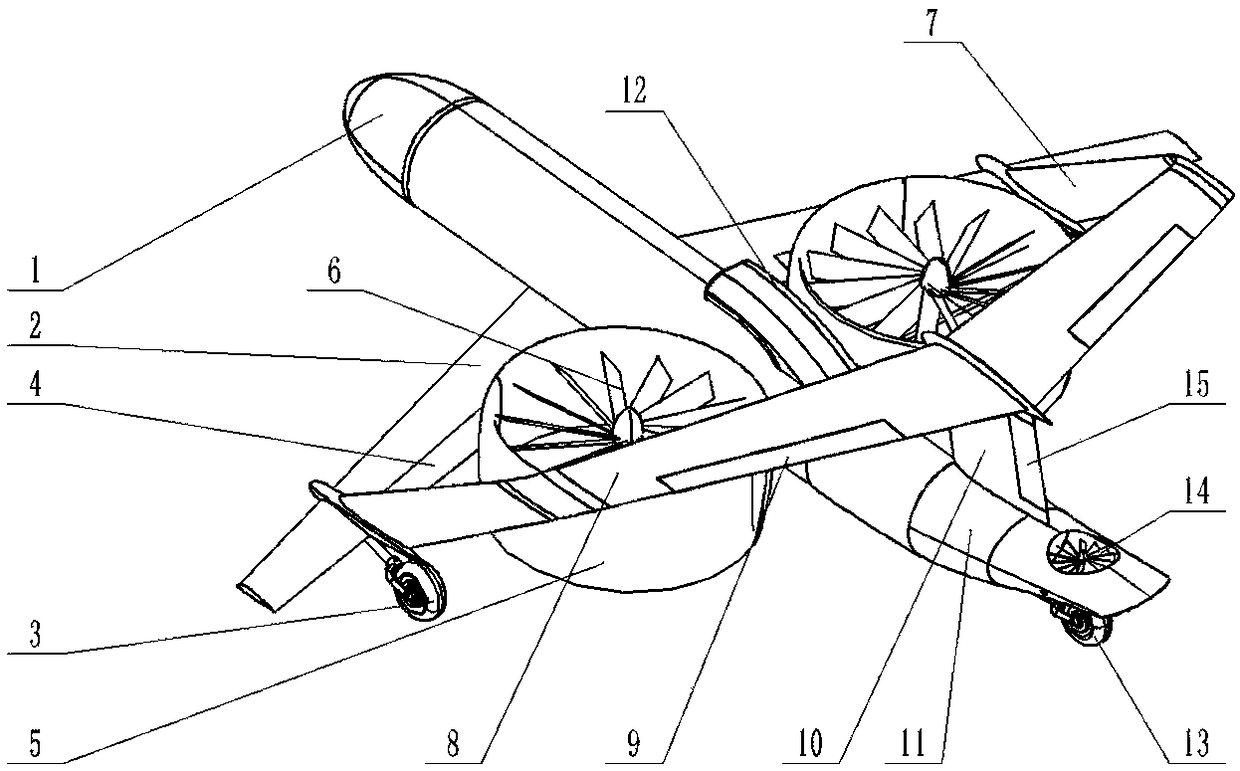

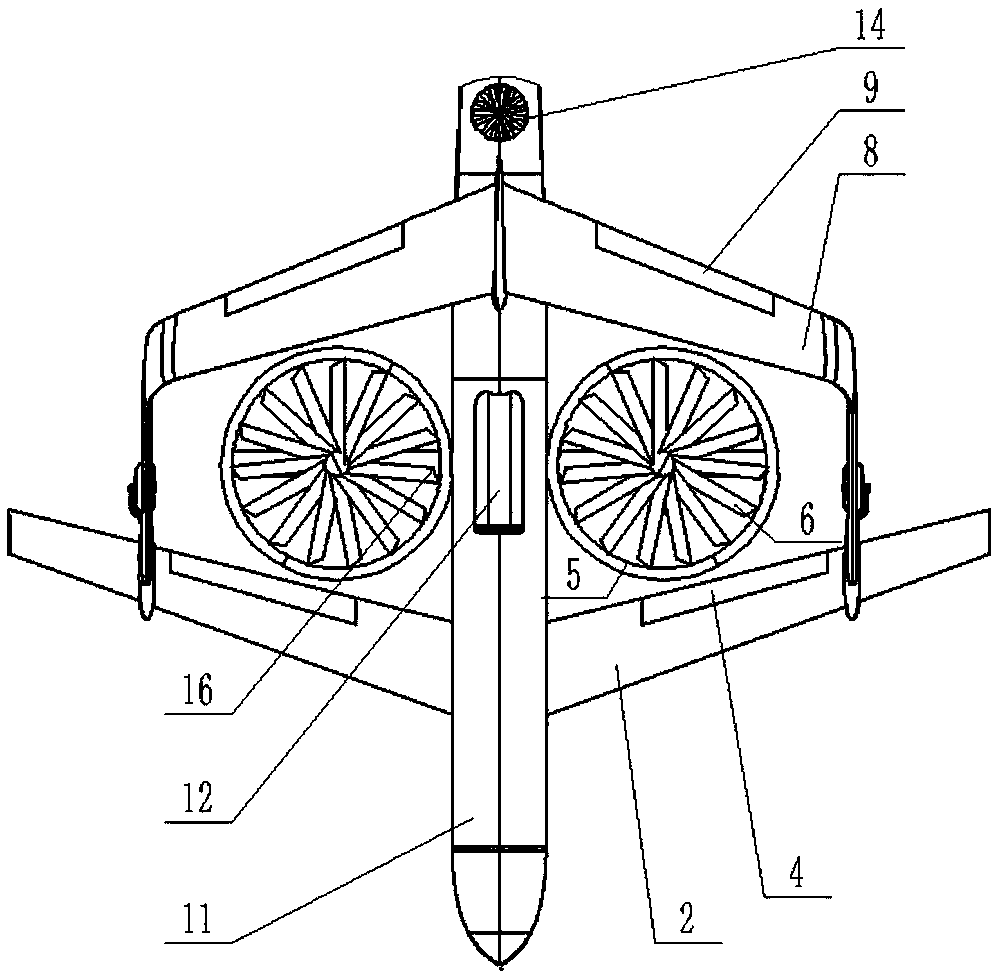

[0030] Such as figure 1 As shown in , an aircraft with vertical take-off and landing with a tilting ducted fan connected to the wing layout, such as Figure 1-Figure 5As shown, the aircraft includes a fuselage 1, connecting wings 2, tilting ducted fans, tail trim fans 14 and landing gear. The connecting wing includes a front wing 2 and a rear wing 8, and there is a certain height difference between the two wings and different distances from the nose along the direction of the fuselage, forming a staggered arrangement in space. The root of the rear wing is connected to the rear of the fuselage by a vertical empennage 10, and the tip of the rear wing is connected to the middle part of the front wing 2 through a vertical connection structure 7. The tilting ducted fan is composed of the main duct 5 and the main fan 6, and is arranged in the middle of the fuselage, avoiding the vertical projection area of the connecting wing, and symmetrically arranged left and right. The engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com