Rapid supporting device for emergency maintenance of pipeline and application method for rapid supporting device

A support device and fast technology, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of unsuitable pipeline repairs, maintenance, low efficiency, Larsen steel sheet piles or ordinary channel steel sheet piles are difficult to press in, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

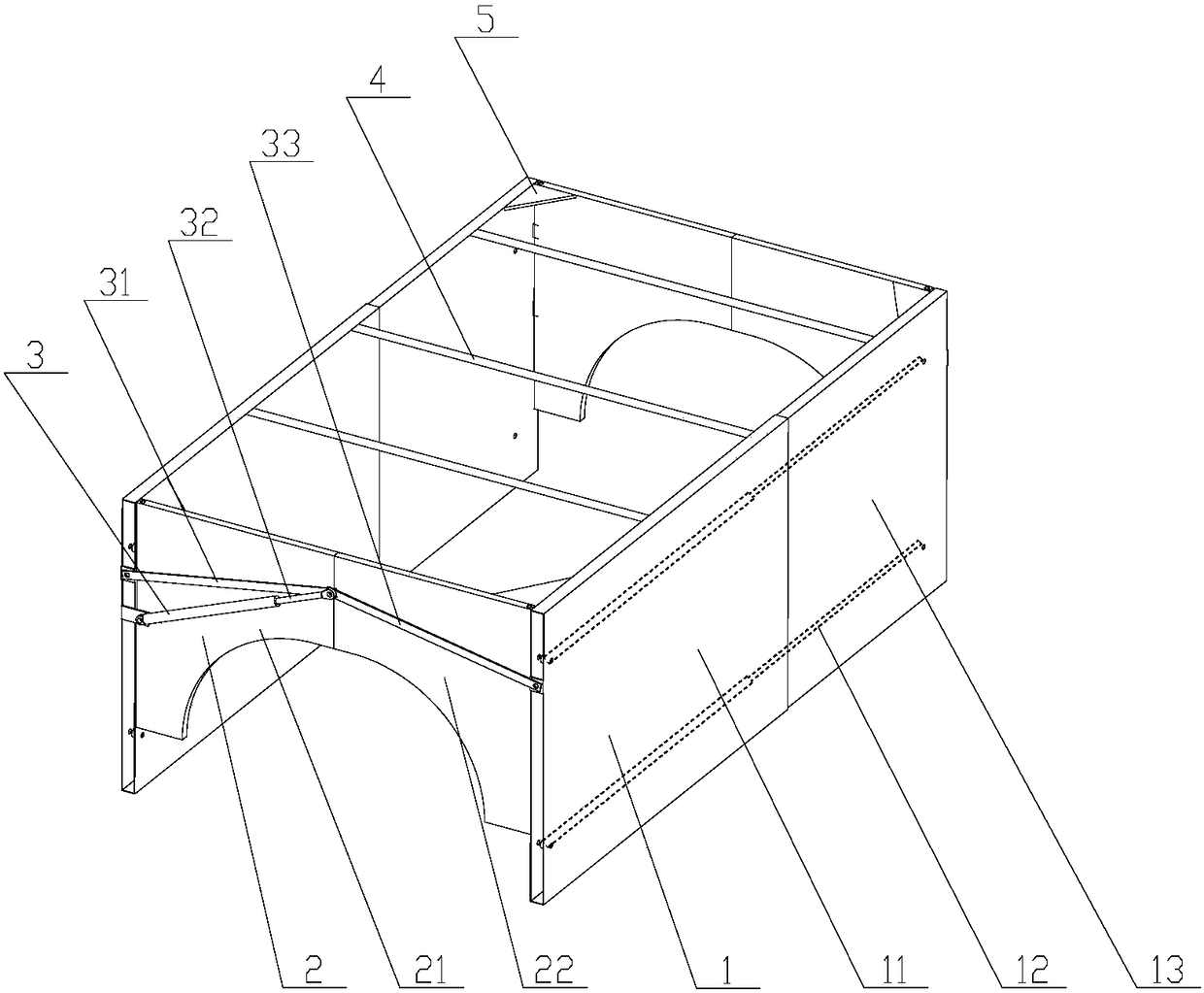

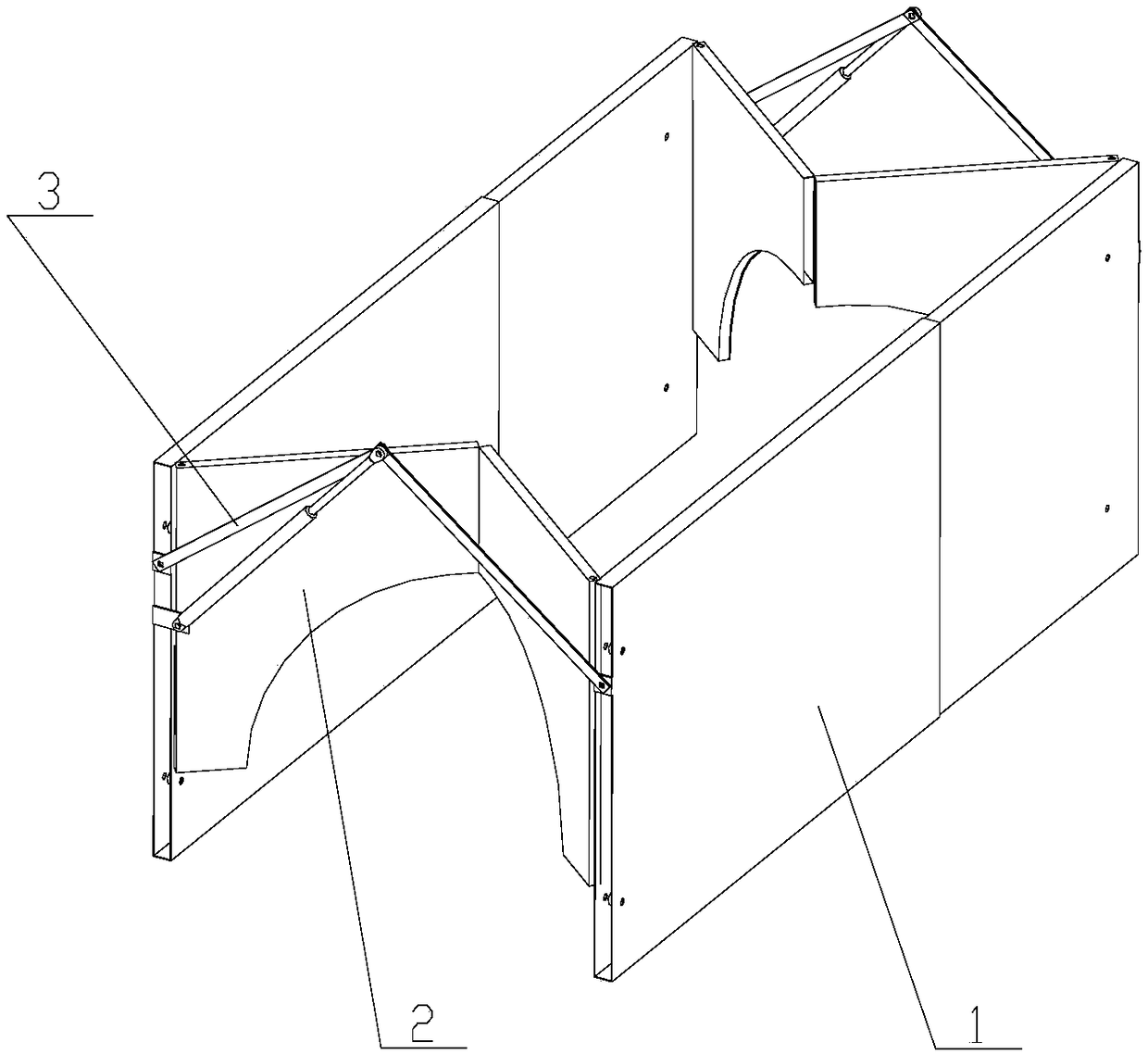

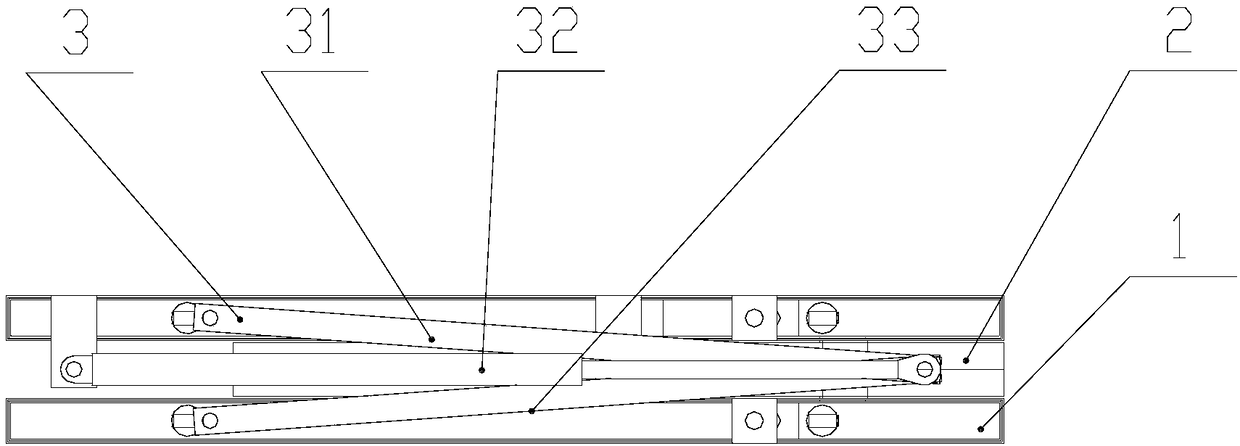

[0029] as attached figure 1 and 2 As shown, the present invention provides a quick support device for pipeline emergency repair, which includes a side support mechanism 1, an end support plate 2, a deployment mechanism 3, a quick support rod 4 and a limit block 5;

[0030] The side support mechanism 1 includes a fixed unit 11, a telescopic drive unit 12 and a movable unit 13; the movable unit 13 is connected with the fixed unit 11 through the telescopic drive unit 12; out or retract to meet the support requirements of different lengths of pits;

[0031] The end support plate 2 is located between the two side support mechanisms 1 , and its two ends are respectively hinged to the two side support mechanisms 1 . It includes: a left end support plate 21 and a right end support plate 22 . One end of the left end support plate 21 is hinged with the left side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com