Open hydraulic fluid flow circuit arrangement and method of controlling the hydraulic circuit

A fluid flow and fluid technology, applied in the field of electronic control devices, can solve problems such as mechanical brake wear and low energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

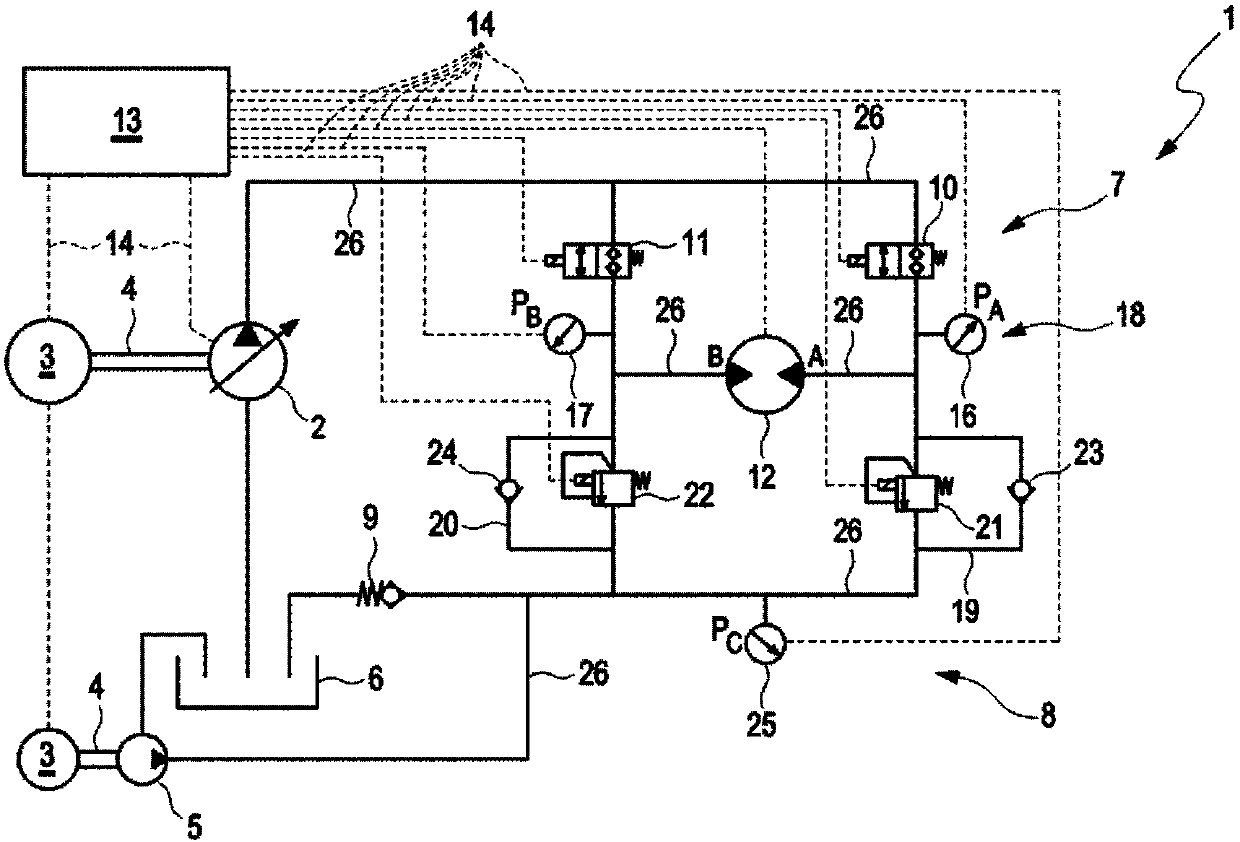

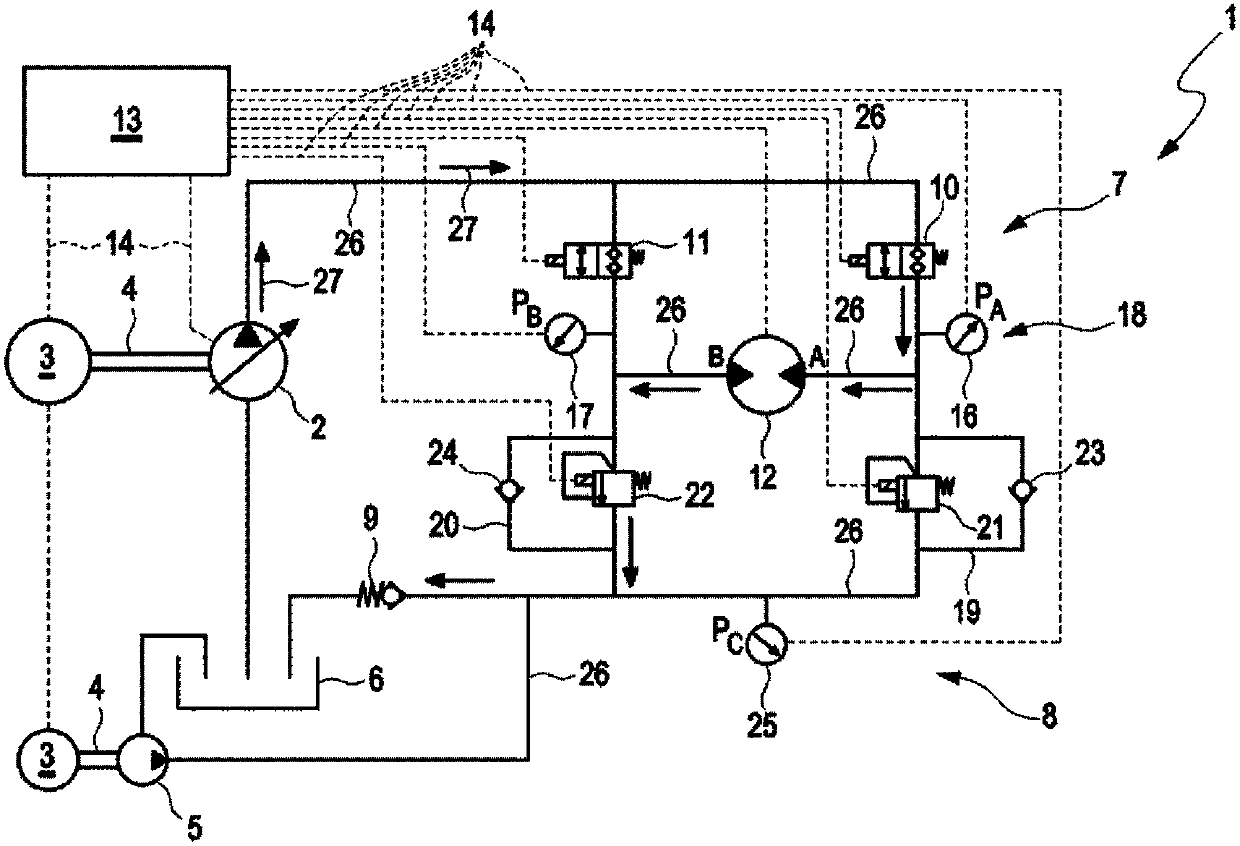

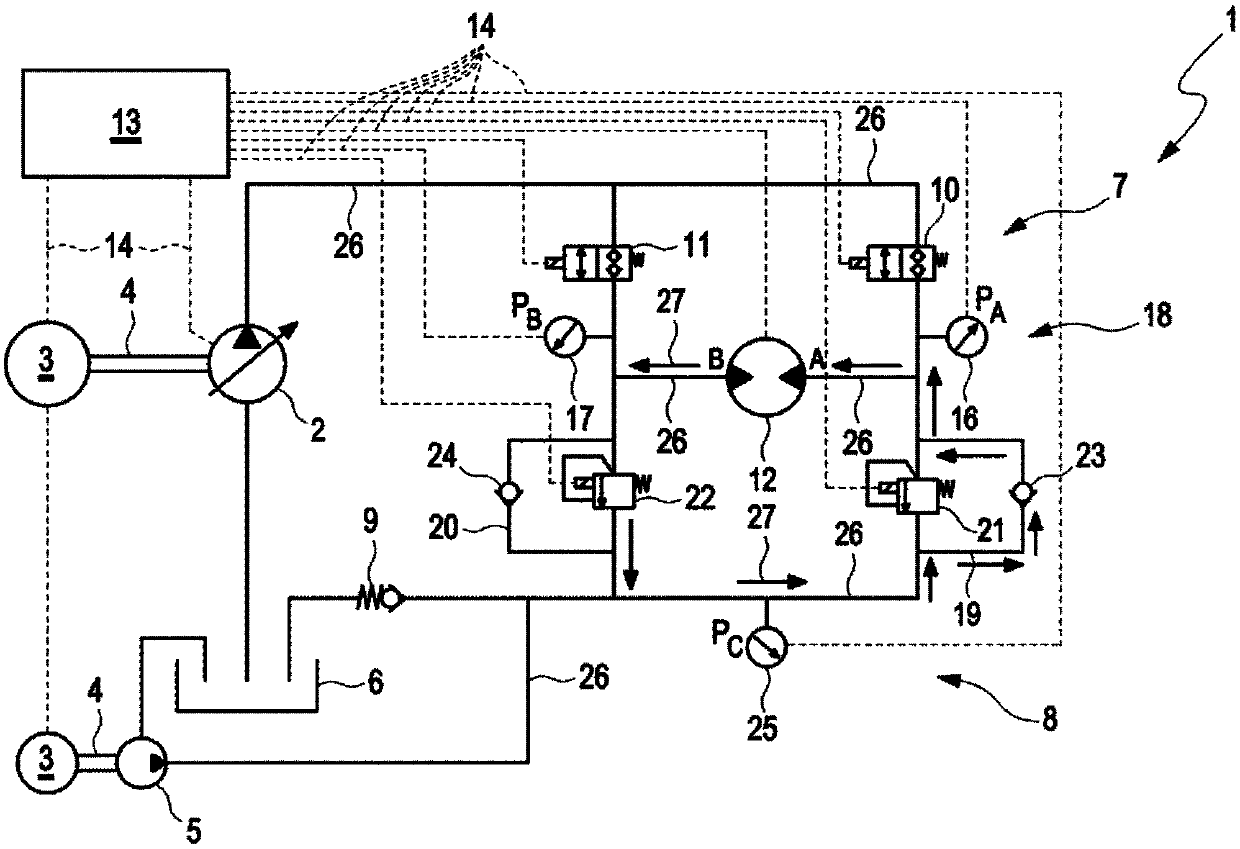

[0034] exist figure 1 In, a first embodiment of a hydraulic propulsion circuit 1 that can be used in mobile vehicles (especially vehicles that use hydraulic systems anyway, for example, forklifts, shovel loaders, excavators, etc.) is shown as a fluid Flow diagram. The presently shown hydraulic propulsion circuit 1 is set up in such a way that the vehicle can be moved in two different (opposite) directions, ie in forward and reverse directions. Since the diagram is set in a symmetrical manner, the propulsion characteristics (maximum speed, torque, etc.) are essentially the same in both directions. This is actually the preferred behavior for machinery such as excavators or forklifts. Furthermore, it can be seen that the hydraulic propulsion circuit 1 is of the open hydraulic fluid flow circuit type.

[0035] In "real life" the output of the main hydraulic pump 2 could also be used for different purposes, like hydraulic pistons for raising the forks of a forklift, hydraulic pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com