Liquid distributing disc structure, evaporator and air-conditioner

A distribution plate and evaporator technology, which is applied in the direction of evaporator/condenser, water shower cooler, heat exchanger, etc., can solve the problem of poor heat exchange effect, insufficient utilization of heat exchange area, and refrigerant flow distribution Inhomogeneity and other problems, to achieve the effect of improving heat transfer efficiency, good heat transfer effect, and uniform flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

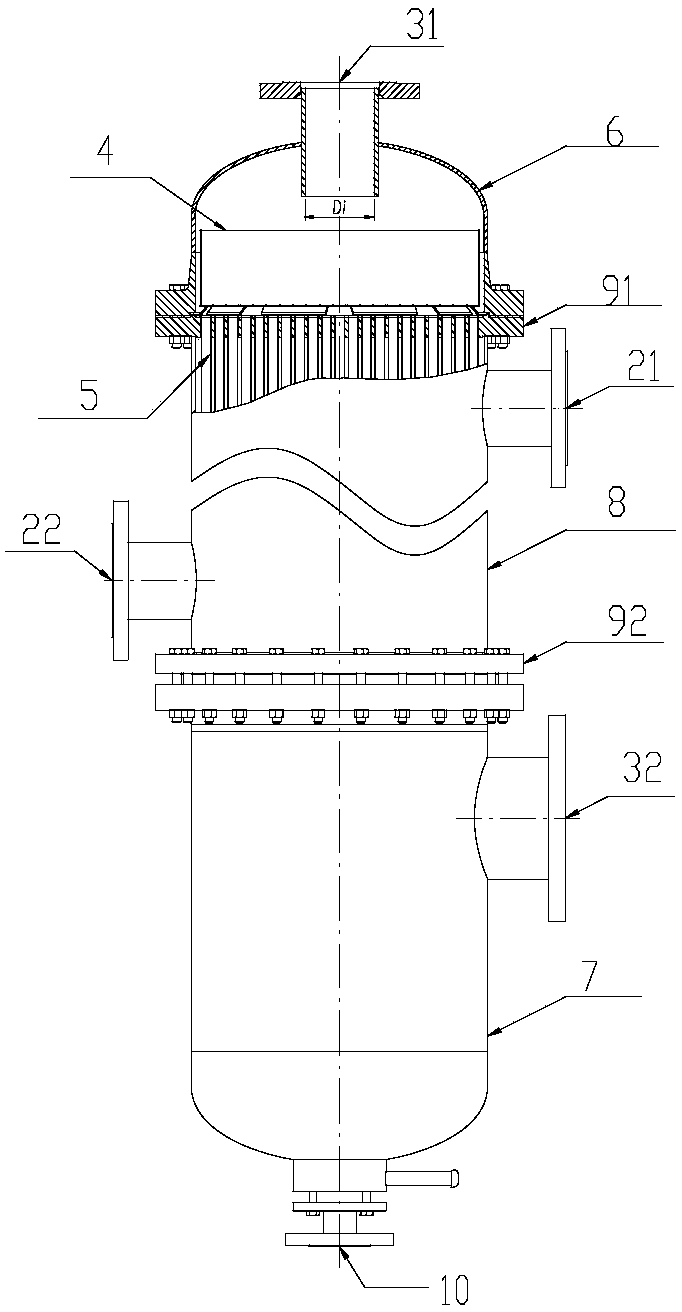

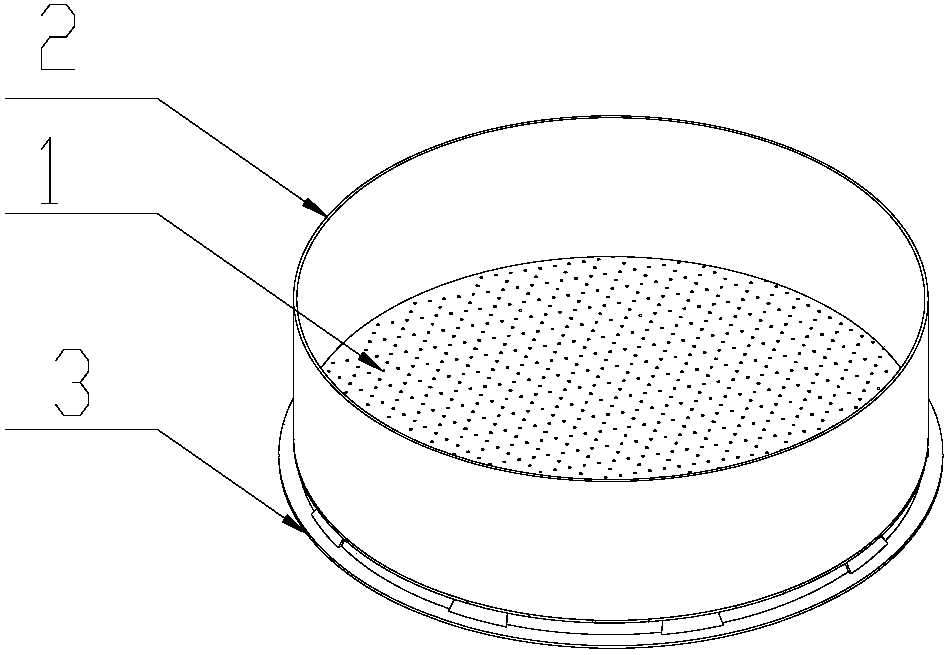

[0054] like Figure 2-6 As shown, the present invention provides a liquid distribution plate structure, which includes:

[0055] The liquid uniform plate 1 is provided with at least one circular liquid uniform hole group 11, each of which includes a first center 111 and a plurality of uniformly distributed circular holes around the first center Liquid equalizing holes 112, a plurality of liquid equalizing holes 112 are arranged around the first circle center to form an annular group of liquid equalizing holes 11, each of the annular liquid equalizing hole groups 11 can be exchanged with one The heat pipes 5 correspond to distribute the liquid into the heat exchange pipes 5 through the plurality of liquid uniform holes 112 .

[0056] With at least one circular liquid uniform hole group arranged on the liquid uniform plate, each said liquid uniform hole group includes a first center and a plurality of circular uniform liquid uniform holes around the first center, Each of the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com