Direct-buried 1KV polyvinyl chloride insulated power cable laying machine with intelligent backfilling

A polyvinyl chloride and power cable technology, applied in cable laying equipment, overhead line/cable equipment, etc., can solve the problems of complicated process, high labor intensity, long time consumption, etc., and achieve simple operation, low labor intensity, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

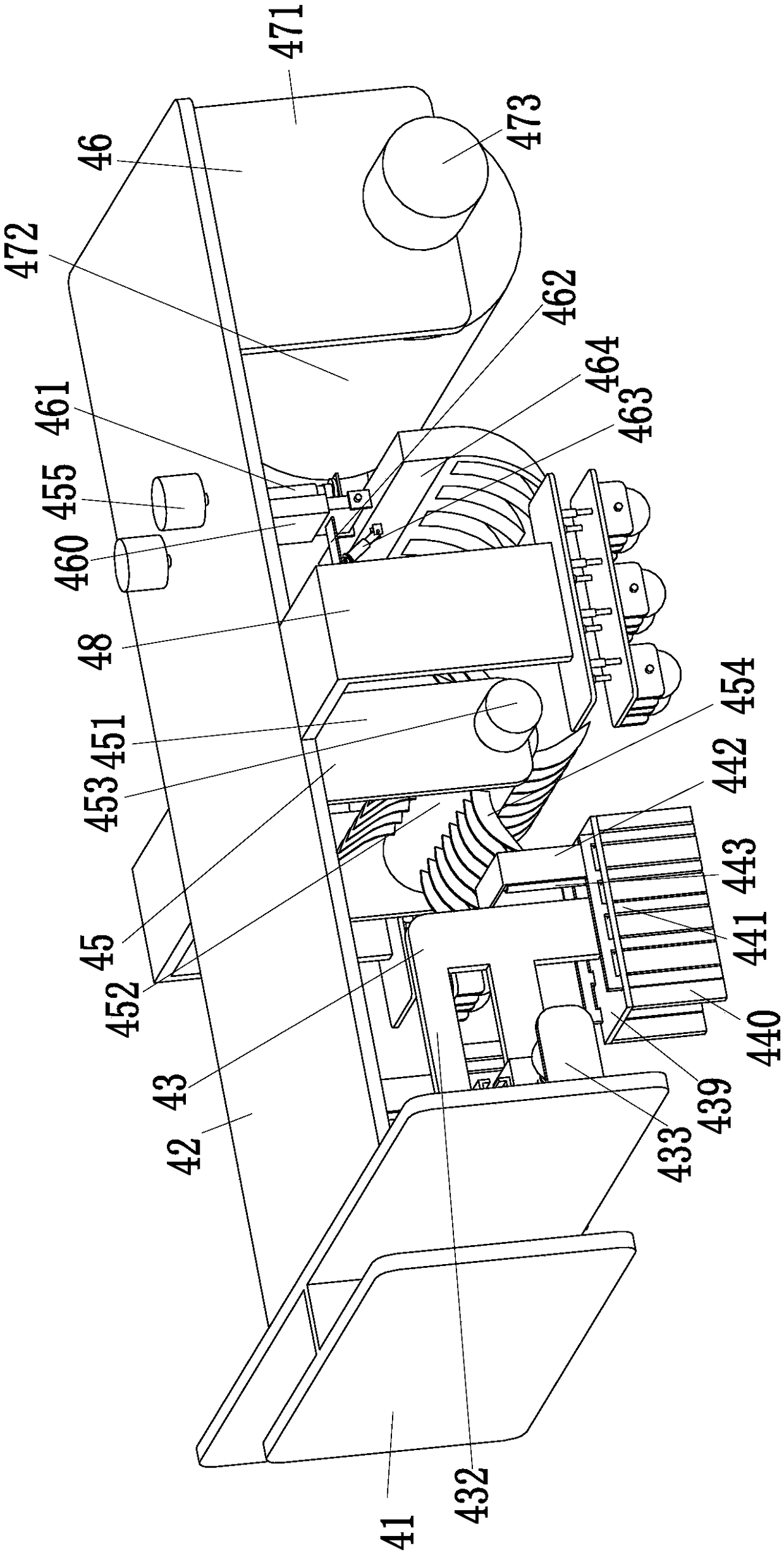

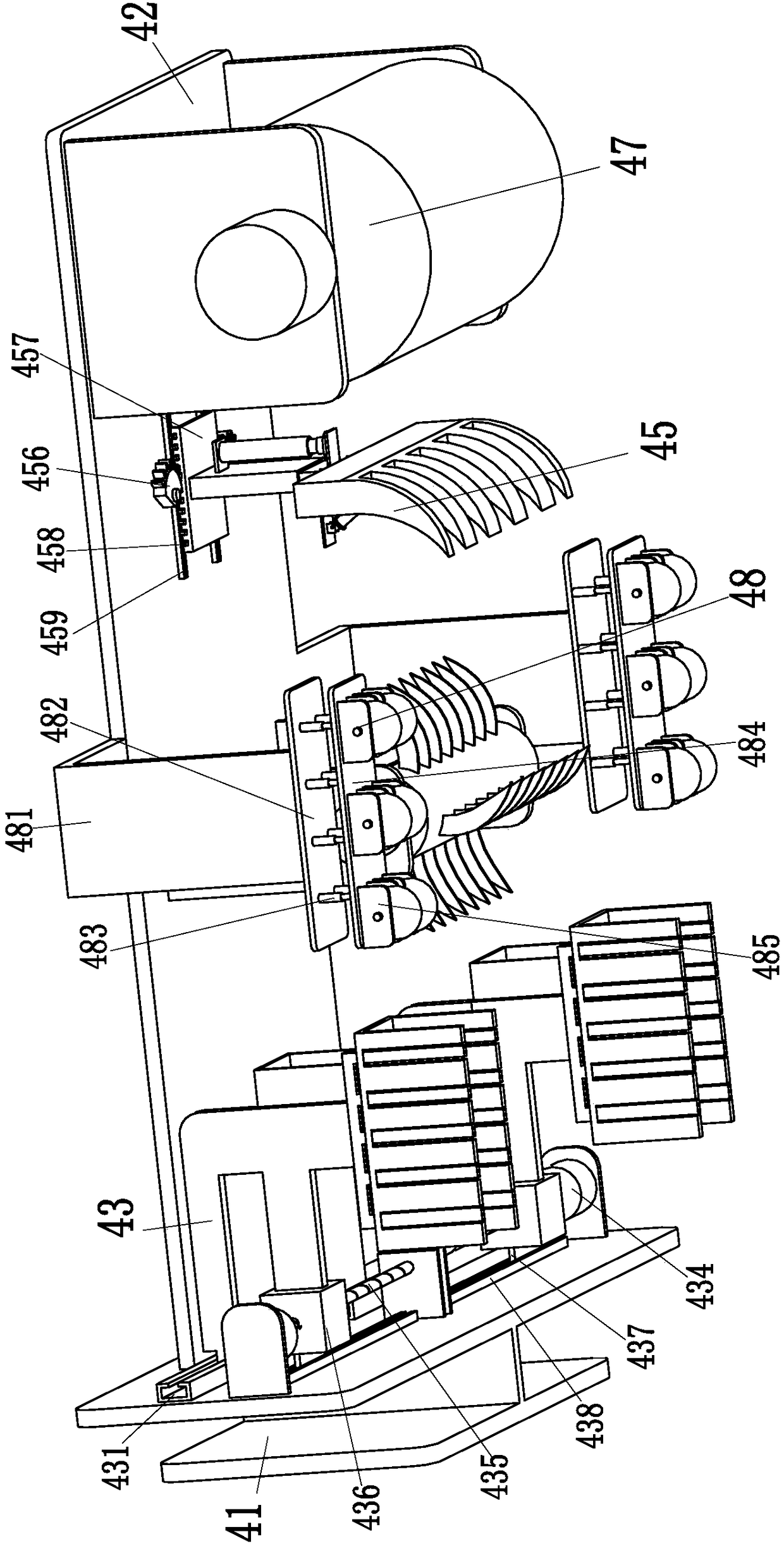

[0021] Such as Figure 1 to Figure 2As shown, in order to achieve the above object, the present invention adopts the following technical solutions: a direct-buried 1KV polyvinyl chloride insulated power cable laying machine that can be intelligently backfilled, including a work frame 41, a horizontal plate 42, two backfill mechanisms 43, loose The soil mechanism 45, the rolling mechanism 47 and two auxiliary mechanisms 48, the two backfilling mechanisms 43 push and backfill the soil on both sides, the soil loosening mechanism 45 loosens the soil, and the rolling mechanism 47 rolls th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com