Automatic gluten cooking device

A cooking device and gluten technology, which are applied in the directions of vegetable protein processing, food forming, food science, etc., can solve the problems of simple equipment and low efficiency, and achieve the effect of standardizing the structure and improving the cooking efficiency of gluten.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

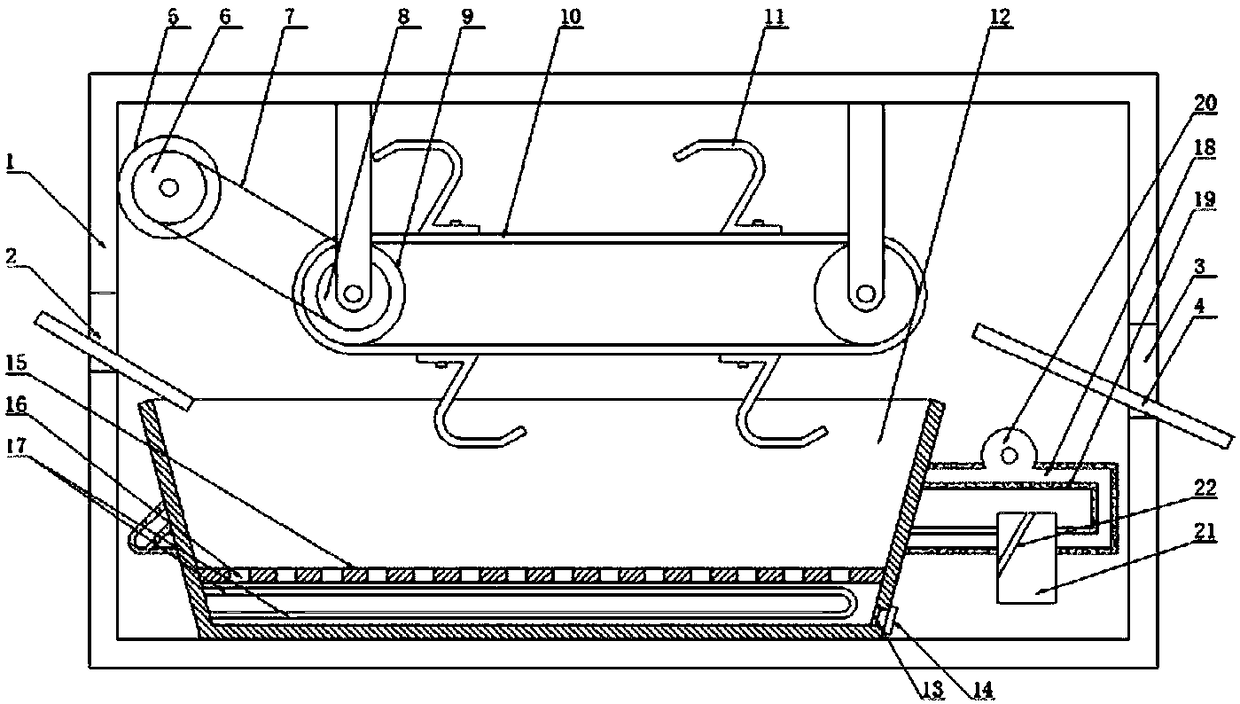

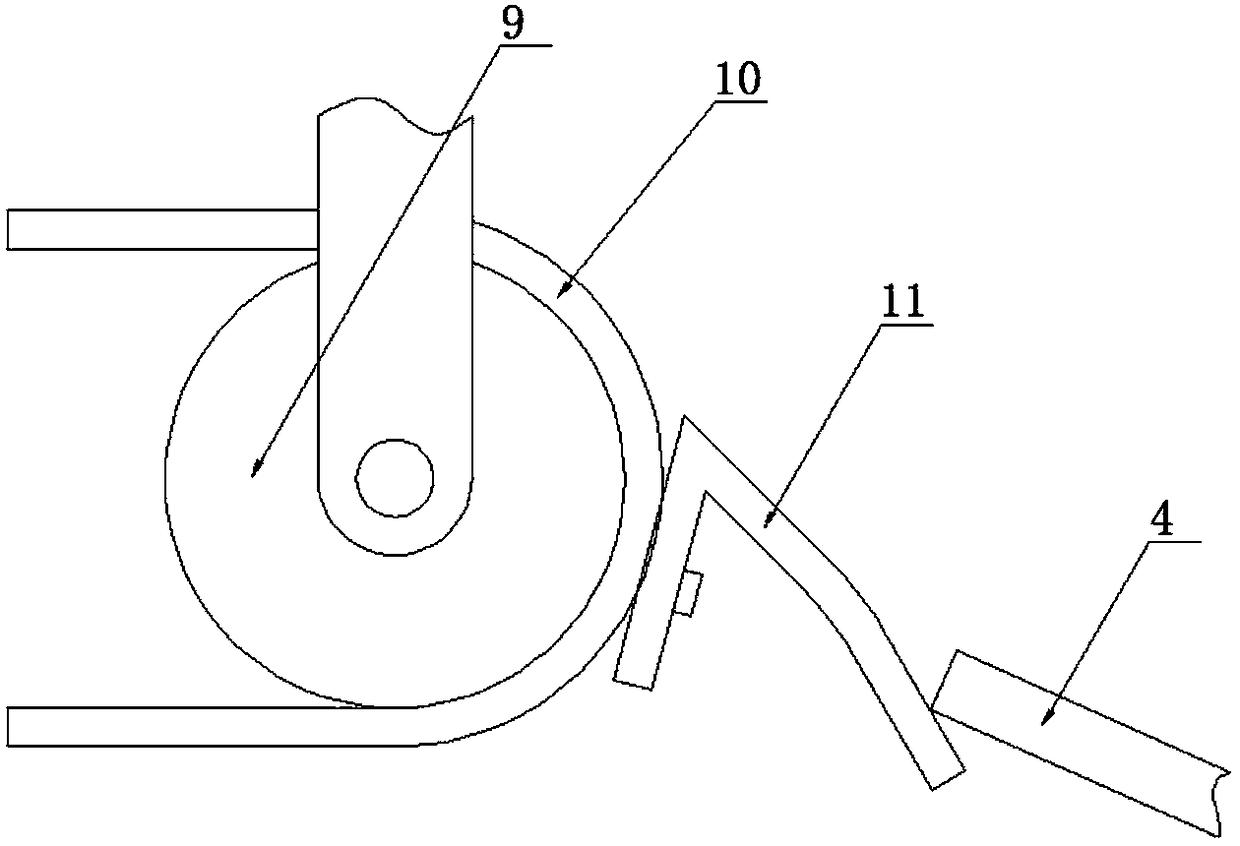

[0011] Example 1, see figure 1 and figure 2 , an automatic gluten cooking device, comprising a body 1, a feed port 2, a discharge port 3, a discharge guide plate 4, a motor 5, a driving pulley 6, a transmission belt 7, a driven pulley 8, a conveyor wheel 9, and a conveyor belt 10 , fishing spoon 11, cooking trough 12, drain hole 13, sealing plug 14, partition 15, through hole 16, heating pipe 17, circulation pipe 18; wherein: one side of body 1 is provided with feeding port 2, and the other side There is a discharge port 3, a discharge guide plate 4 is installed in the discharge port 3, a motor 5 is installed on the top of the body 1, and a driving pulley 6 is installed at the output end of the motor 5, and the driving pulley 6 is connected to the driven pulley through the transmission belt 7. 8 are connected, the driven pulley 8 is coaxially fixedly connected with the conveying wheel 9, and the conveying wheels 9 are connected by a conveyor belt 10, a scoop 11 is installed ...

Embodiment 2

[0012] Example 2, see figure 2 , an automatic gluten cooking device, wherein: the circulation pipe 18 is covered with a layer of insulation layer 19 to ensure that the heat will not be lost when the water is in the circulation pipe 18. All the other are with embodiment 1.

[0013] working principle:

[0014] Gluten strips are dropped into the cooking tank 12 from the feeding port 2, and sink to the partition plate 15. At this time, the heating pipe 17 is powered on and generates heat to heat the water in the cooking tank 12. When the water boils Afterwards, the gluten strips can be cooked, and the cooked gluten strips will float to the water surface due to their density being lower than that of water. The wheel 8, the conveying wheel 9, and the conveyor belt 10 drive the scoop 11 to move. When the scoop 11 moves to the bottom, the scoop 11 will extend into the shallow water to pick up the gluten strips floating on the water. And continue to move, when the scoop 11 moves to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com