Long-bone fracture reset force testing device

A technology for testing device and reset force, applied in medical science, external fixator, surgery, etc., can solve the problems of insufficient displacement and increased workload of patients, and achieve the effect of easy disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

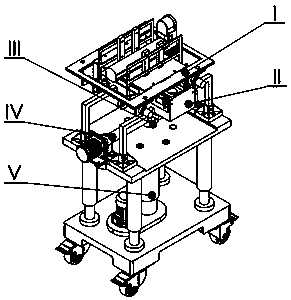

[0029] see figure 1 , The long bone fracture reduction force testing device includes a clamping mechanism (I), a lateral reduction mechanism (II), a T-shaped connection mechanism (III), a traction reduction mechanism (IV) and a lifting mechanism (V). It is characterized in that the clamping mechanism (I) is connected with the sliding block (24) in the horizontal reset mechanism (II) through the connecting plate (1), and the horizontal reset mechanism is connected with the traction reset mechanism (IV) through the T-shaped connection mechanism (III). The leading screw slide block (36) is connected, and the traction reset mechanism (IV) is installed on the lifting frame (27) in the hoisting mechanism (V) by bearing blocks (25, 35).

Embodiment 2

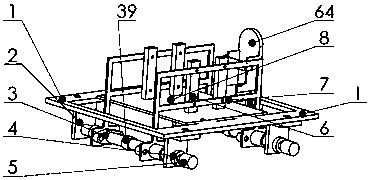

[0031] see figure 2 , this embodiment is basically the same as Embodiment 1, and the special feature is that: the clamping structure (1) includes clamping and fixing parts (6, 7) on both sides of the thigh, a leg contact bottom plate (8), a connecting plate (1 ), servo motor (5), lead screw (39) and foot fixture (64). The clamping fixtures (6, 7) on both sides of the thighs are synchronously driven by a lead screw (39) controlled by two small servo motors (5), and the clamping fixtures (6, 7) include two clamping frames (7) and four identical rectangular blocks (6), each rectangular block (6) is connected to the clamping frame (7) by 2 screws, and a patch type force sensor is attached to the rectangular block (6); two The screw (39) rotates through the 4 L-shaped connecting plates (2) below the connecting plate (1), and two screw sliders (3) are screwed on each screw (39) installed in parallel. The two ends of the lower side of the holder (7) are respectively fixed on the two...

Embodiment 3

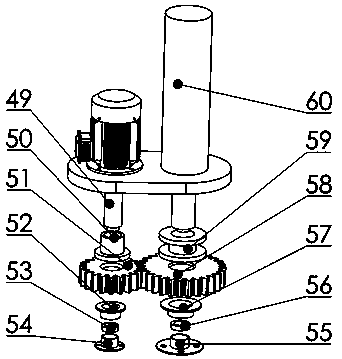

[0033] see image 3 , this embodiment is basically the same as Embodiment 1, and the special feature is that: the foot fixing part (64) includes an h-shaped connecting part (11), a screw (17), a foot connecting part (9, 10), 6 a fixing nut, the foot connecting piece (9, 10) includes a foot connecting plate (9) and a foot fixing ring (10), and one end of the foot fixing ring (10) is hinged to the foot connecting plate (9) One side is connected, and the other end of the foot fixing ring (10) is fixed to the other side of the foot connecting plate (9) by screws. The screw (17) is placed in a long groove at the front end of the connecting plate (1), and the screw ( 17) Fix on both sides of the long slot with large nuts (13, 14), and two h-shaped connectors (11) are fixed at both ends of the screw (17) with small nuts (12, 15, 16, 18), h-shaped connection The part (11) is connected with the foot connecting plate (9) through screws, and the said foot fixing part can adjust the scre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap