Viscous chemical material high efficiency stirring mixing device

A stirring and viscous technology, which is applied in the field of high-efficiency stirring and mixing devices for viscous chemical materials, can solve the problems of poor mixing degree of materials, inability to mix materials, and materials that take a long time to achieve the effect of full mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

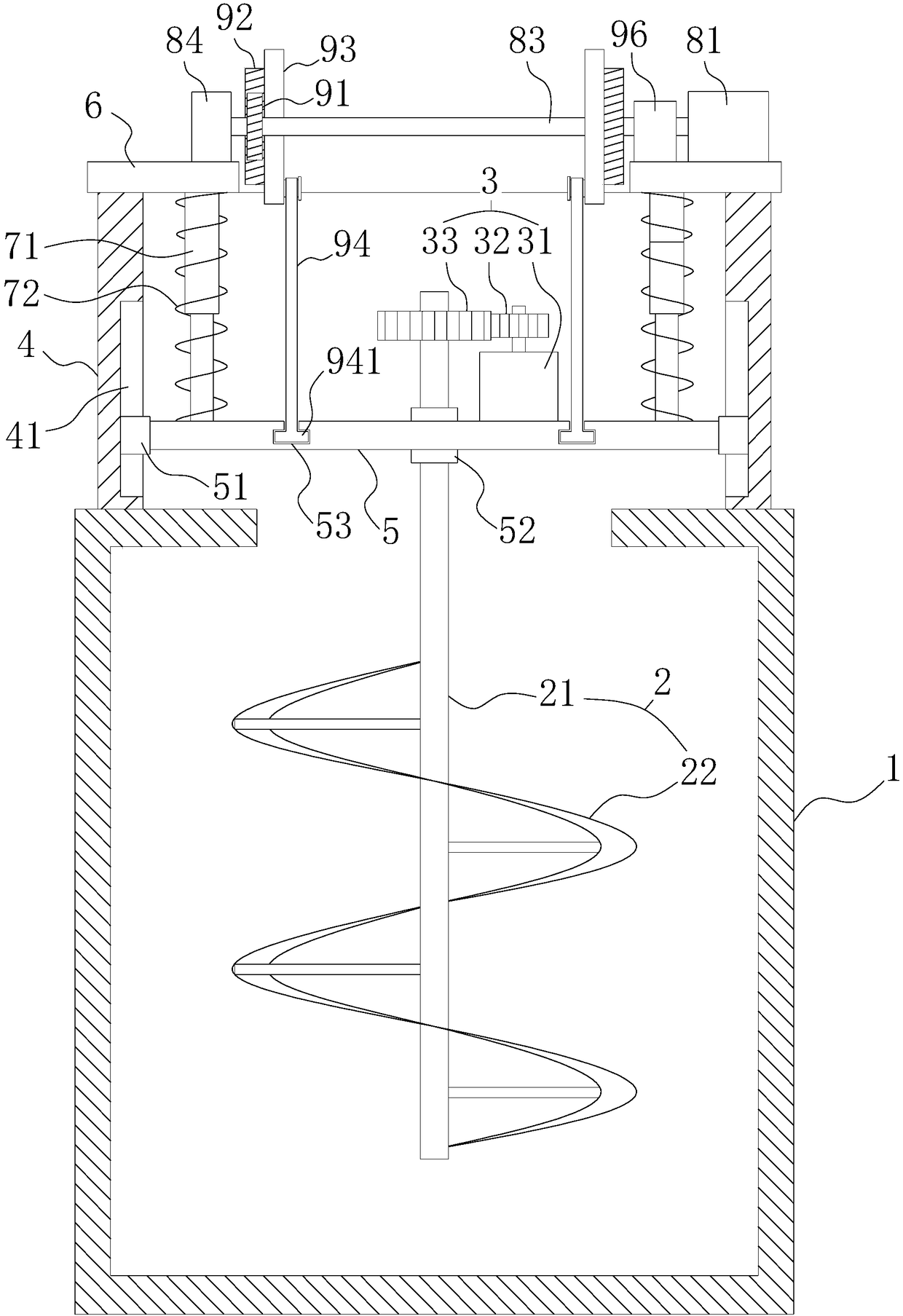

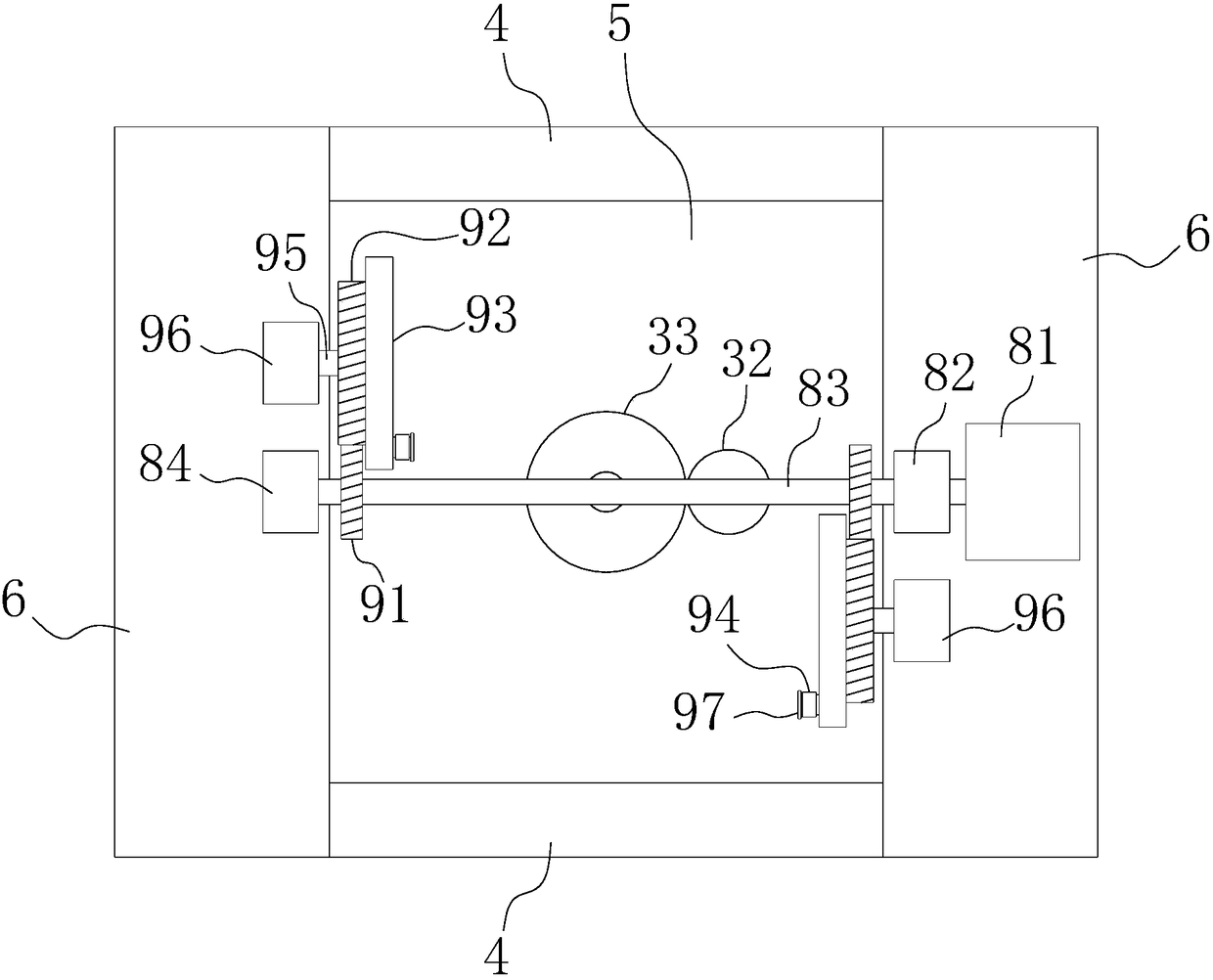

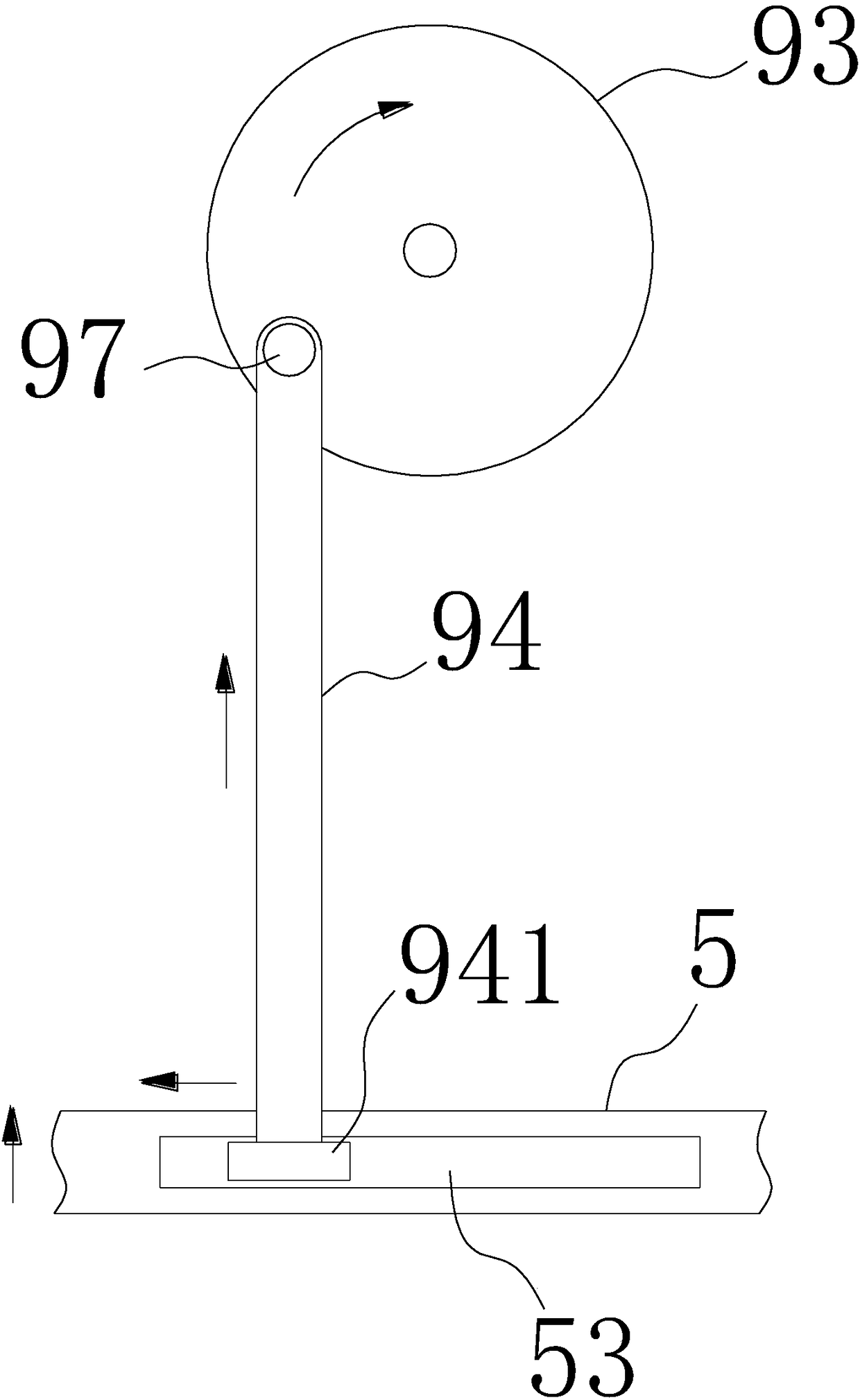

[0032] like Figure 1-Figure 6 As shown, a viscous chemical material high-efficiency mixing device provided by the present invention includes a mixing drum 1, a stirring paddle 2, a first drive assembly 3, a lateral support plate 4, a movable plate 5, a lateral support plate 6, a telescopic Rod 71, the second drive assembly and the linkage assembly.

[0033] The mixing drum 1 is used to hold materials.

[0034] The stirring paddle 2 extends into the stirring drum 1 and is used to stir the materials.

[0035] The first drive assembly 3 is used to drive the stirring paddle 2 to rotate.

[0036] The number of the lateral support plates 4 is four, all of which are installed above the mixing drum 1 and form a frame structure, wherein the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com