Preparation method of silver phosphate-compounded bismuth phosphate photocatalyst

A composite bismuth phosphate and photocatalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of unstable components of silver phosphate photocatalysts, reduced catalyst degradation performance, and high production costs. , to achieve the effect of improving photocatalytic efficiency, stable composition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] Example 1

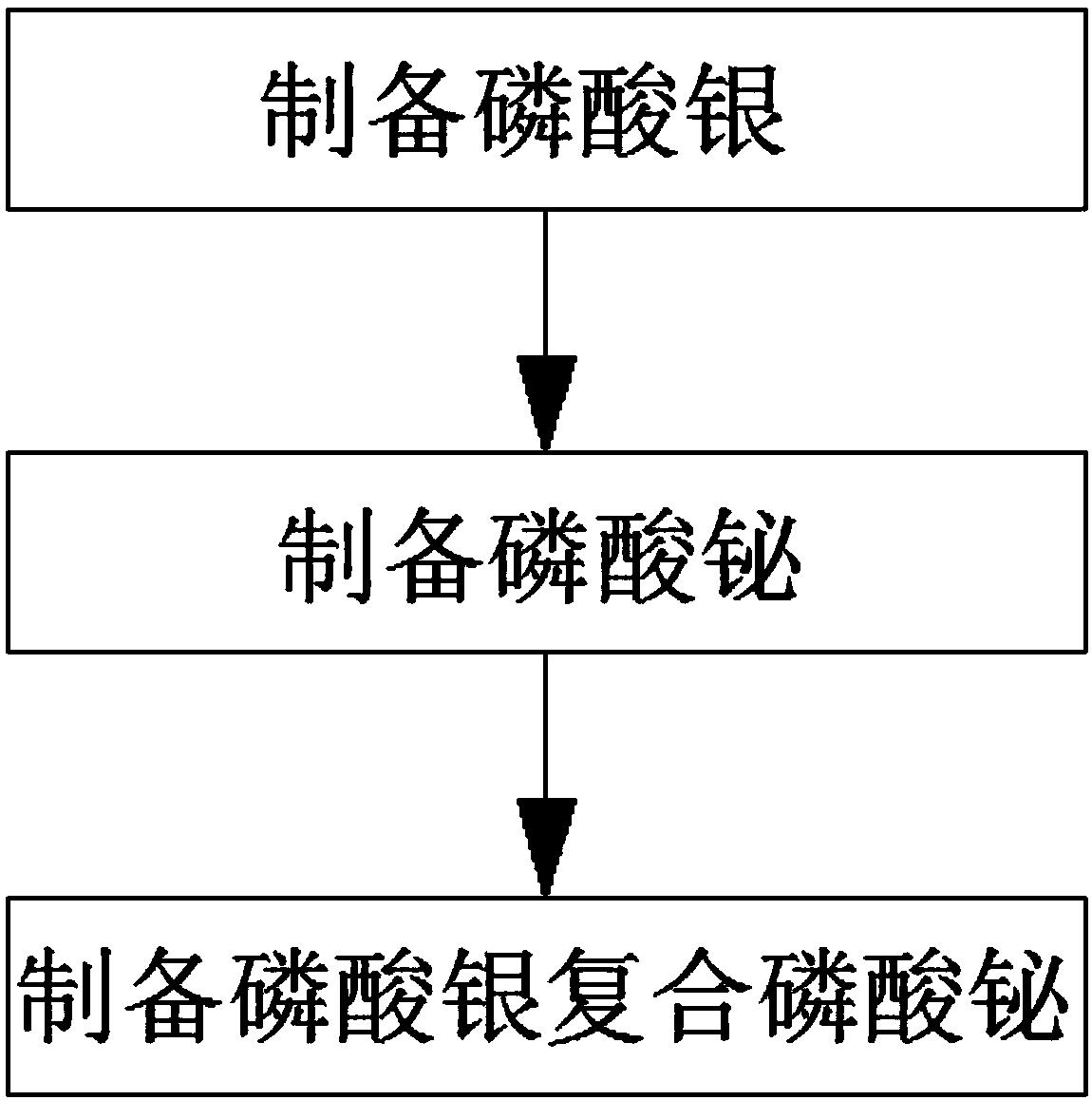

[0019] The preparation method of the silver phosphate composite bismuth phosphate photocatalyst includes the following steps:

[0020] S1: Preparation of silver phosphate: add 4 parts of silver nitrate to 80 parts of distilled water, oscillate with ultrasonic waves at room temperature, slowly add dilute ammonia water under stirring, start to produce brown precipitate, and then stop adding dilute ammonia water when the precipitate is dissolved. The concentration of ammonia water is 1.2mol / L, the adding rate of the dilute ammonia water is 3 drops / sec, the stirring is accelerated, the speed of the accelerated stirring is 300 revolutions / min, the stirring time is 10 minutes, and 140 parts of 0.2mol / L are added Continue stirring for 1.6 hours. Centrifuge and filter to obtain the precipitate. Wash 4 times. The washing method is to use deionized water and absolute ethanol for cleaning, drying, and drying at a vacuum of 80 Celsius, get silver phosphate;

[0021] S2: Prep...

Example Embodiment

[0023] Example 2

[0024] The preparation method of the silver phosphate composite bismuth phosphate photocatalyst includes the following steps:

[0025] S1: Preparation of silver phosphate: Add 3 parts of silver nitrate to 75 parts of distilled water, oscillate with ultrasonic waves at room temperature, and slowly add dilute ammonia under stirring to start to form a brown precipitate, and then when the precipitate is dissolved, stop adding dilute ammonia. The concentration of ammonia water is 1mol / L, the adding rate of the dilute ammonia water is 2 drops / sec, the stirring is accelerated, the speed of the accelerated stirring is 250 revolutions / min, the stirring time is 8 minutes, and then 120 parts of 0.15 mol / L are added Sodium hydrogen phosphate, continue to stir, stirring time is 1.2 hours, centrifuge, filter, get the precipitate, wash 3 times, washing method is to use deionized water and absolute ethanol for cleaning, drying, drying temperature is vacuum 70 degrees Celsius , ...

Example Embodiment

[0028] Example 3

[0029] The preparation method of the silver phosphate composite bismuth phosphate photocatalyst includes the following steps:

[0030] S1: Preparation of silver phosphate: add 2 parts of silver nitrate to 50 parts of distilled water, oscillate with ultrasonic waves at room temperature, slowly add dilute ammonia with stirring, start to form brown precipitate, and then stop adding dilute ammonia when the precipitate is dissolved. The concentration of ammonia water is 0.8 mol / L, the adding rate of the dilute ammonia water is 1 drop / second, the stirring is accelerated, the speed of the accelerated stirring is 200 rpm, the stirring time is 6 minutes, and then 100 parts of 0.1 mol / L are added Sodium hydrogen phosphate, continue to stir, stirring time is 0.8 hours, centrifuge, filter, get the precipitate, wash twice, washing method is to use deionized water and absolute ethanol for cleaning, drying, drying temperature is vacuum 60 Celsius, get silver phosphate;

[0031]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap