Parallel separation chamber of super-conducting magnetic separator and method of achieving uniform water distribution therewith

A sorting cavity and superconducting magnetic technology, applied in the direction of high gradient magnetic separator, etc., can solve the problem of uneven water distribution, achieve the effect of improving the precision of ore dressing, avoiding clogging, improving the processing precision and the stability of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

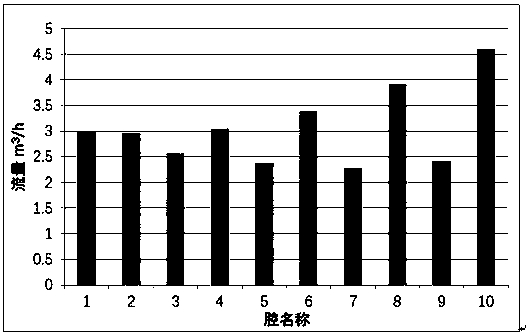

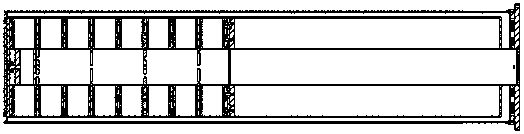

[0034] 500mm caliber, effective magnetic field length 1200mm Superconducting magnetic separator, divided into 10 sorting chambers, each sorting chamber has an effective steel wool area length of 100mm; the inner diameter of the water inlet pipe is 150mm, and the cross-sectional area is 17662.5mm 2 , the interval of the return water channel outside the outer sleeve is 30mm, and the converted cross-sectional area is about 20000mm 2 . If the flow field is not optimized, the pressure distribution of the ore feed flow field of the 10 cavities is as follows figure 1 As shown, the ore flow estimation of 10 cavities is as follows figure 2 shown. Utilize the technical solution provided by this patent to greatly reduce the cross-sectional area of the water channel of the outer sleeve to less than 3000mm 2 , the total cross-sectional area of water distribution of 5 groups of outer sleeve water channels is less than 15000mm 2 , at this time the flow estimates of the 10 cavities a...

Embodiment 2

[0036] 500mm caliber, effective magnetic field length 1200mm Superconducting magnetic separator, divided into 10 sorting chambers, each sorting chamber has an effective steel wool area length of 100mm; the inner diameter of the water inlet pipe is 150mm, and the cross-sectional area is 17662.5mm 2 , the interval of the return water channel outside the outer sleeve is 30mm, and the converted cross-sectional area is about 20000mm 2 . If the flow field is not optimized, the pressure distribution of the ore feed flow field of the 10 cavities is as follows figure 1 As shown, the ore flow estimation of 10 cavities is as follows figure 2 shown. Using the technical solution provided by this patent, a baffle is added to the steel wool cross-section of the 10 cavities, and small holes with a diameter of 5mm are drilled on the baffle, and the total water cross-sectional area of all the small water holes is 1500mm 2 , the total cross-sectional area of 10 parallel cavity baffles is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com