Electrode holder mold-repairing compensation device and method and electrode holder device

A compensation device and welding gun technology, applied in welding equipment, resistance welding equipment, electrode features, etc., can solve the problems of workpiece clamping error, welding pressure reduction, cylinder working efficiency reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An embodiment of the present invention provides a welding tongs mold repair compensation device, including a welding tongs body 100, a Z-axis movement assembly 200 for driving the welding tongs body 100 to move along the Z axis, and a device for recording the replacement of a new electrode cap by the welding tongs body 100 The absolute encoder value of the Z-axis movement component 200 when the rear welding tongs body 100 is in the initial state and the absolute encoder and controller of the Z-axis movement component 200 absolute value encoder value when the welding tongs body 100 is in the initial state after mold repair; The controller is connected with the absolute encoder so that the controller can retrieve the data in the absolute encoder; the controller is connected with the Z-axis motion assembly 200 so that the controller can control the Z-axis motion assembly 200 .

[0044] An embodiment of the present invention provides a welding tongs mold repair compensation ...

Embodiment 2

[0048] An embodiment of the present invention provides a welding tongs mold repair compensation method, including the following steps: after the welding tongs body 100 is replaced with a new electrode cap, record the absolute value encoder value of the Z-axis motion assembly 200 when the welding tongs body 100 is in the initial state , to obtain the first recorded value; after the welding tongs body 100 is repaired, record the absolute encoder value of the Z-axis motion assembly 200 when the welding tongs body 100 is in the initial state, to obtain the second recorded value; for the first recorded value and The difference operation is performed on the second recorded value to obtain the third recorded value; the Z-axis value of the welding tong body 100 is compensated by the controller according to the third recorded value, so as to ensure the Z-axis position accuracy.

[0049] An embodiment of the present invention provides a welding tongs mold repair compensation method, incl...

Embodiment 3

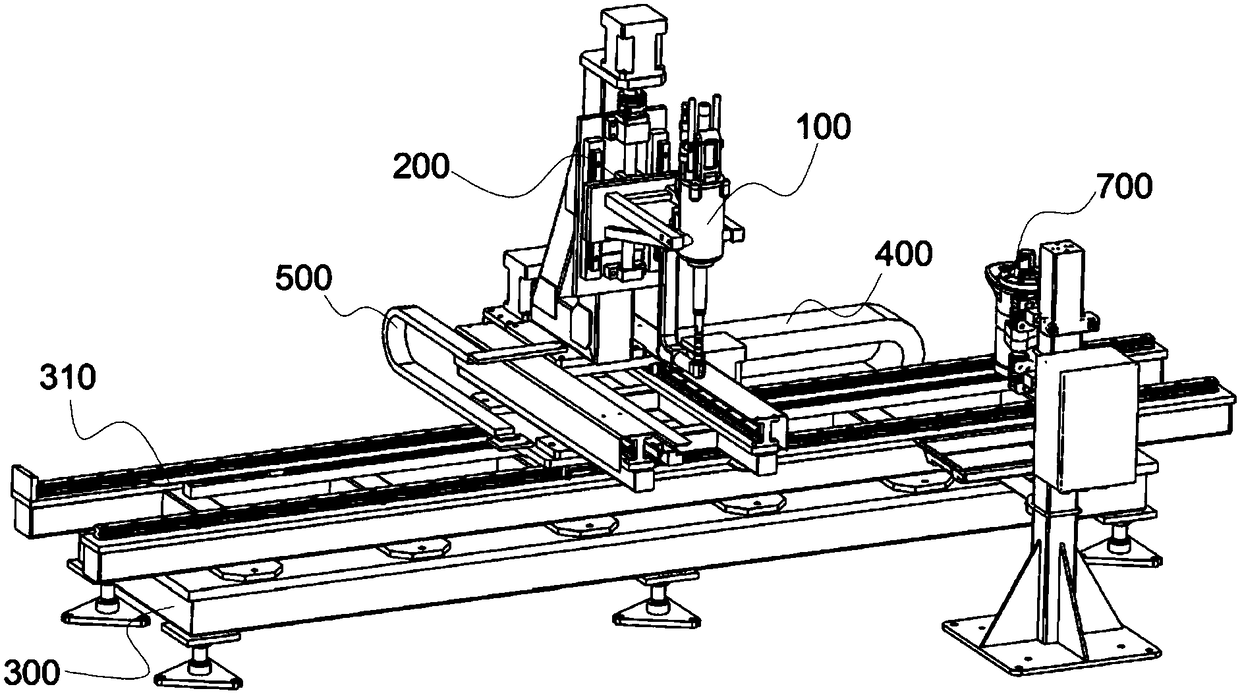

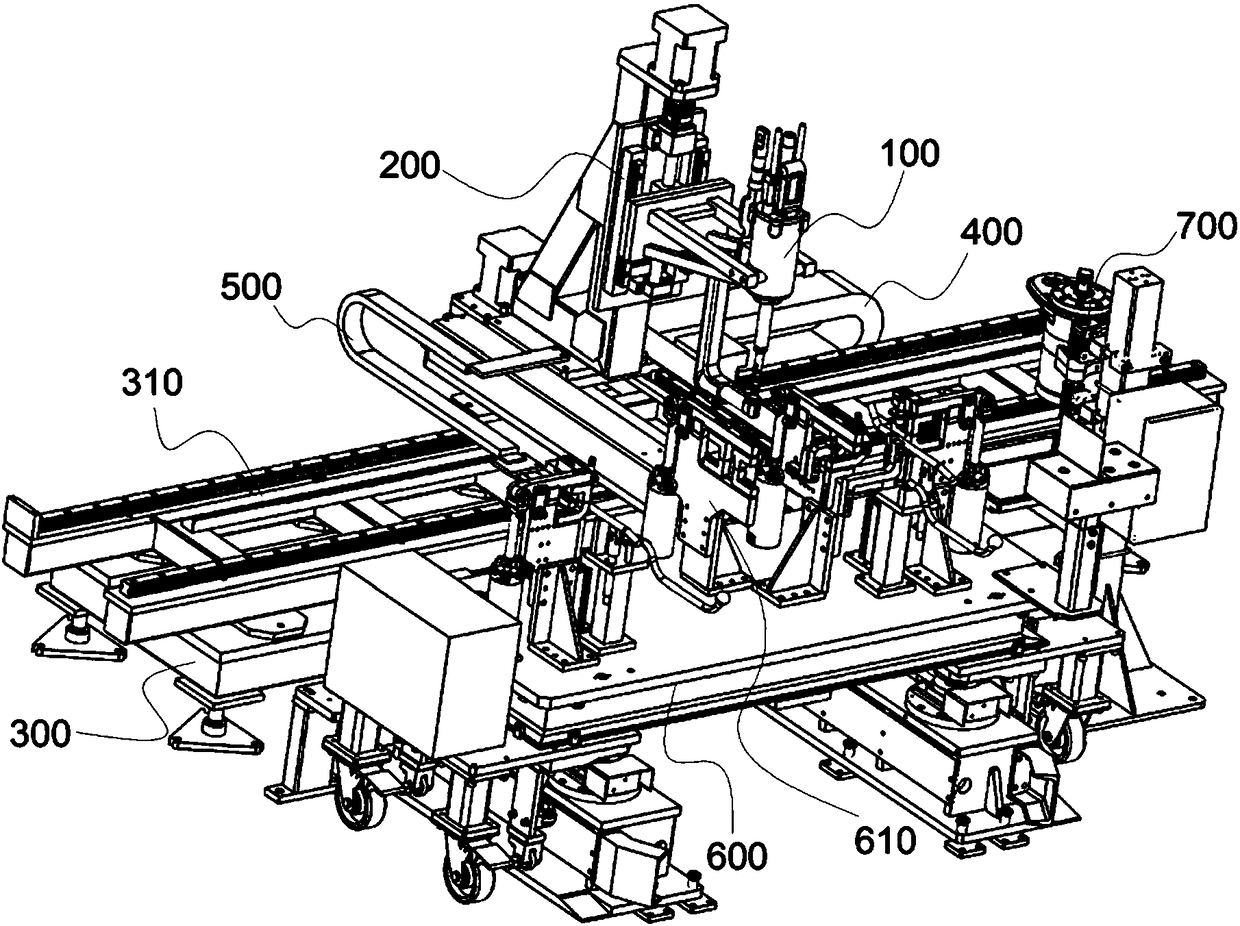

[0053] The embodiment of the present invention provides a welding tongs device, including: a base 300, a power assembly disposed on the base 300, a working platform 600 disposed on the base 300, and a welding tongs mold repair compensation device; the power assembly and the corresponding welding tongs body 100 connections.

[0054] The embodiment of the present invention provides a welding tongs device, including: a base 300, a power assembly disposed on the base 300, a working platform 600 disposed on the base 300, and a welding tongs mold repair compensation device; the power assembly and the corresponding welding tongs body 100 connection, the welding tongs device has the above-mentioned advantages compared with the prior art, which will not be repeated here.

[0055] In an optional solution of this embodiment, the power assembly includes an X-axis movement assembly 400 for driving the welding tongs body 100 to move along the X-axis, a Y-axis movement assembly 500 for drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com