A Kiss Cut Waverider Design Method with a Given 3D Front Line

A design method and waverider technology, applied in computer-aided design, calculation, instrument, etc., can solve the problem that the three-dimensional leading edge line cannot be directly specified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

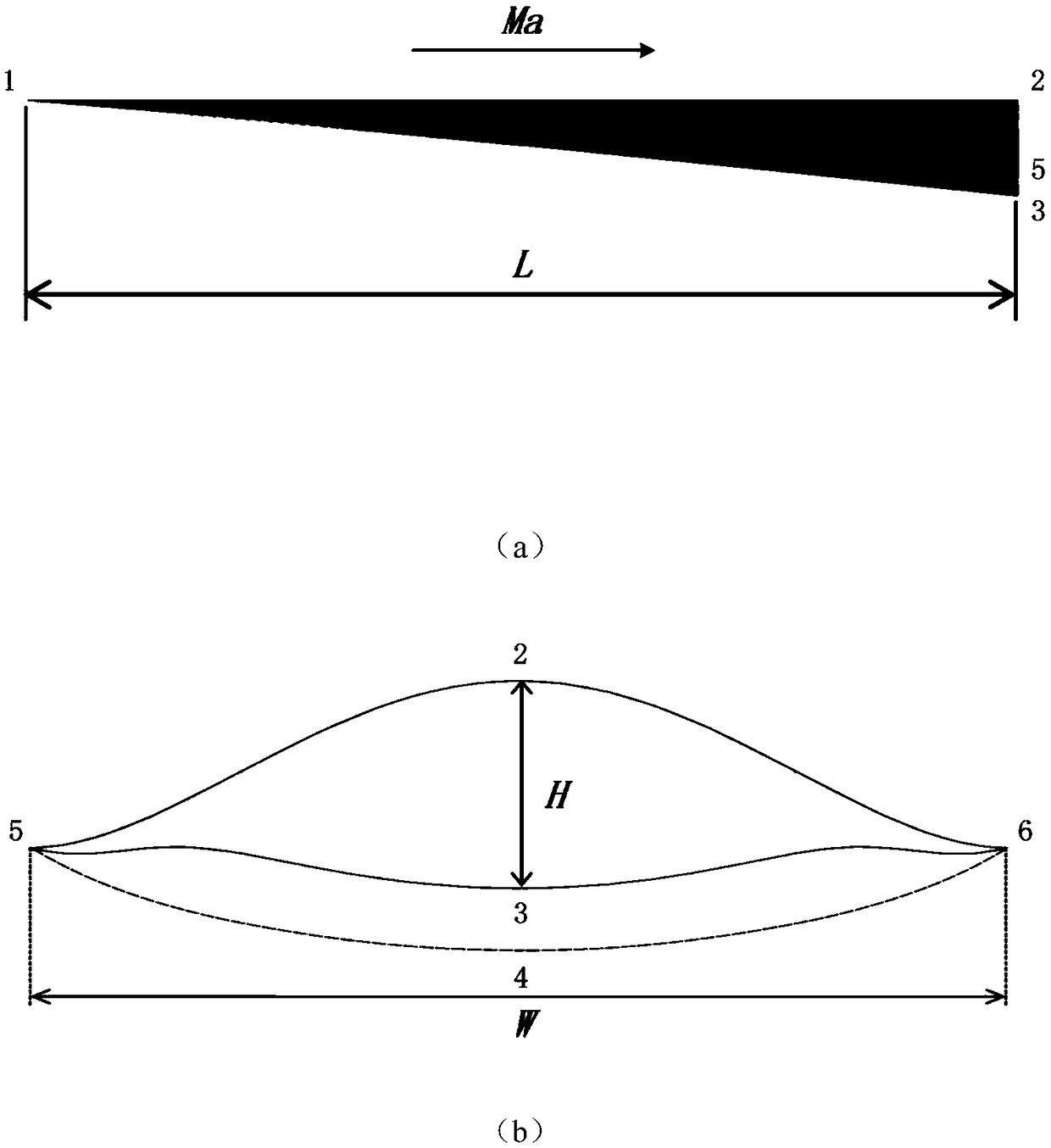

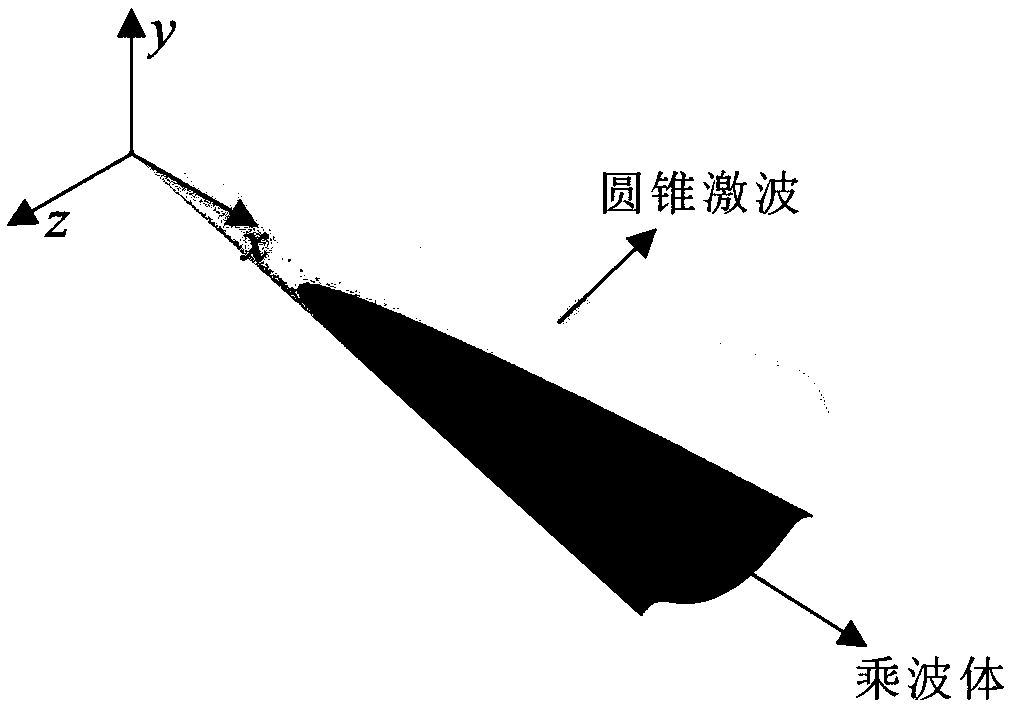

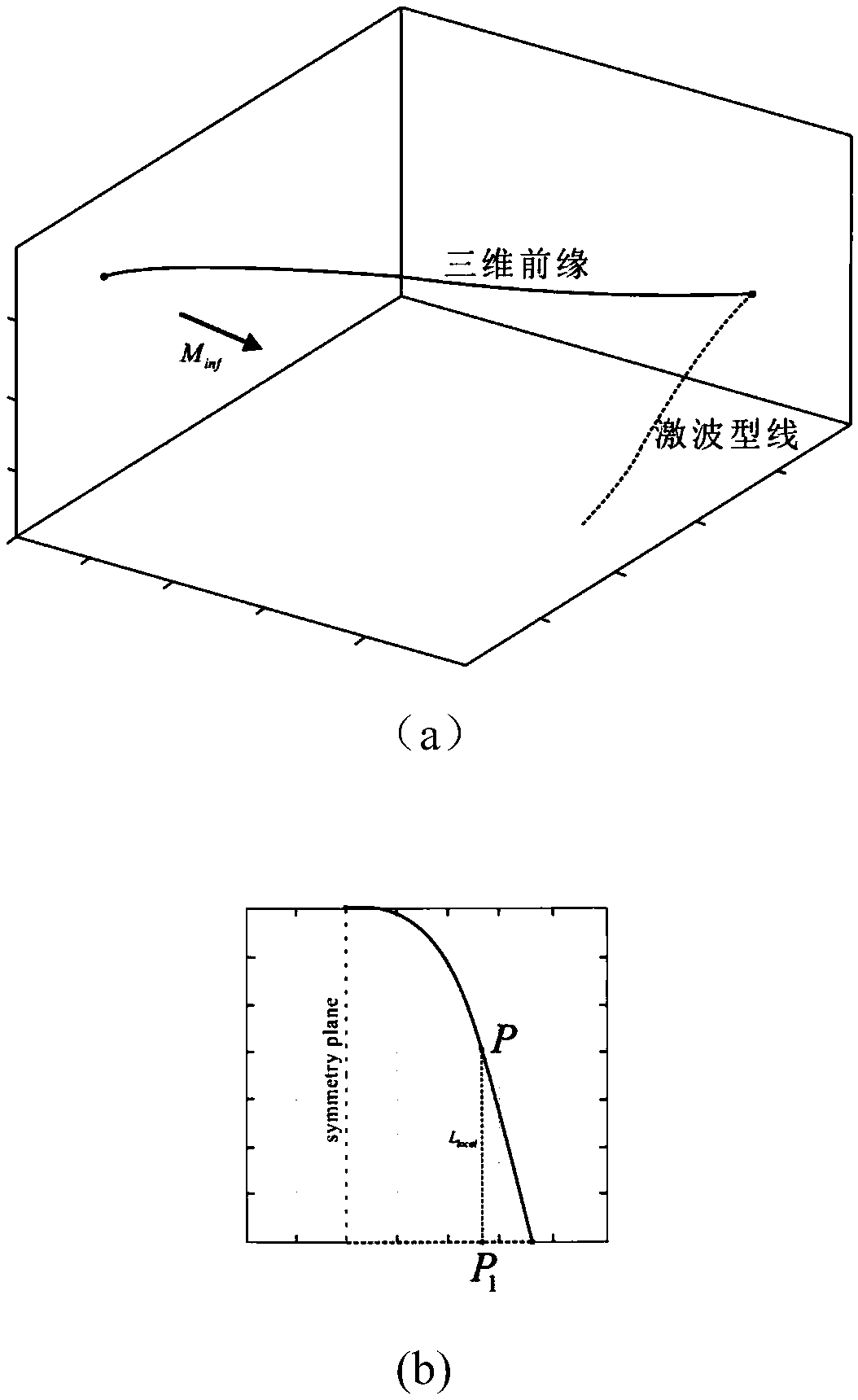

[0050] Firstly, the typical lines and surfaces of the waveriders to be designed are introduced, refer to figure 1 is a schematic diagram of the geometric parameters of the waverider part, figure 1 where Ma is the Mach number of the incoming flow, L is the length of the waverider, H is the height of the waverider, W is the wingspan of the waverider, points 1, 2, 3, and 4 are the three-dimensional leading edge line and upper edge of the waverider, respectively. The midpoint of the surface exit profile, the bottom surface exit profile, and the shock wave exit profile, and points 5 and 6 are the three-dimensional leading edge line, top surface exit profile, bottom surface exit profile, and shock wave exit of the waverider The two intersection points where these four typical molded lines intersect, curve 5-1-6 is the three-dimensional leading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com