A kind of preparation method of sand base material with fast water filtering function

A water filtering, sand-based technology, applied in ceramic products, household appliances, other household appliances, etc., can solve the problems of complex preparation process and difficult industrialization implementation, and achieve large water permeability coefficient, good weather resistance, and long-term water filtering effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

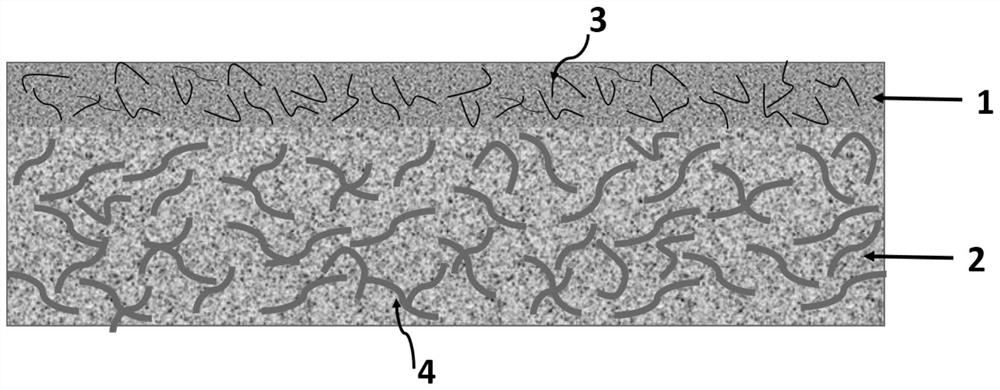

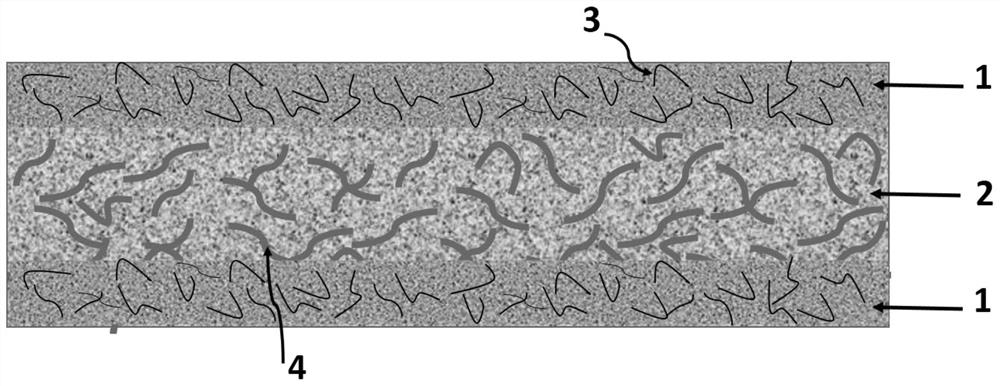

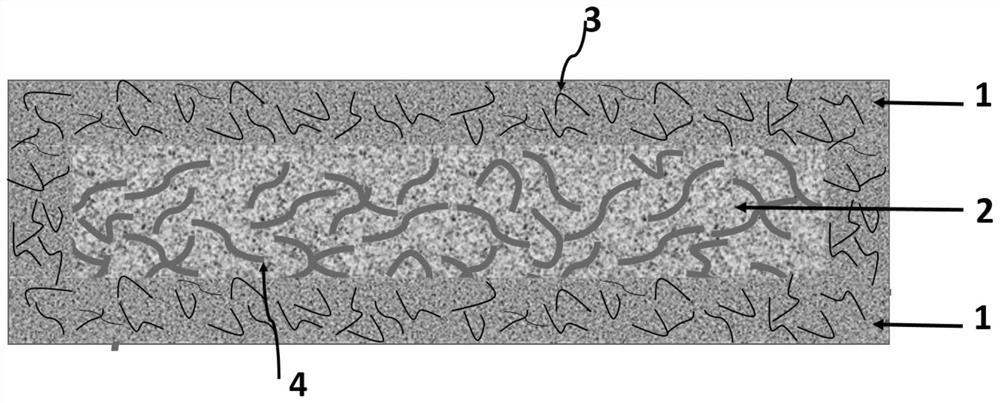

Image

Examples

Embodiment 1

[0043] 1. Preparation method of water filtering functional layer material

[0044] Put 500g of coated sand in JJ-5 cement mortar mixer and stir, use 25g of hexanediol diglycidyl ether as adhesive, and 7.5g of supporting polyetheramine modified isophorone diamine as curing agent, 0.6g polypropylene fiber (1cm), 4g inorganic pigment iron oxide red (Tianjin Bodi Chemical Industry Co., Ltd.), obtain the water filtering functional layer material after fully stirring, stand-by.

[0045] 2. Preparation method of water-permeable functional layer material

[0046] Put 2000g basalt gravel (3-8mm continuous gradation), 500g ordinary portland cement PO42.5, 2g basalt fiber chopped strands (4cm), 140g water, 5.28g polycarboxylate high-performance water reducing agent, put in Stir in a JJ-5 cement mortar mixer, and get the permeable functional layer material after fully stirring, ready for use.

[0047] 3. Preparation method of water-filtering and permeable composite materials

[0048] T...

Embodiment 2

[0050] 1. Preparation and method of water filtering functional layer material

[0051] Same as Example 1

[0052] 2. Preparation and method of water-permeable functional layer materials

[0053] Same as Example 1

[0054] 3. Preparation and method of filter functional materials

[0055] The water-filtering and water-permeable composite material is prepared by static pressure molding. The water-filtering functional layer material is first placed in a stainless steel mold (200*100*50mm), and the universal press is turned on to apply a pressure of 1.5MPa. After 5 minutes, lift the pressure head . Then add the water-permeable functional layer material into the mold, continue to apply a pressure of 2 MPa for 10 minutes, turn over the mold and the uncured composite material together after 2 hours, and cure and form at room temperature without special maintenance. After 24 hours, the mold is demoulded to obtain a filter functional material with a microporous filter surface layer ...

Embodiment 3

[0057] 1. Preparation and method of water filtering functional layer material

[0058] Same as Example 1

[0059] 2. Preparation and method of water-permeable functional layer materials

[0060] Same as Example 1

[0061] 3. Preparation and method of filter functional materials

[0062] The water-filtering and permeable composite material is prepared by combining vibration molding and static pressure molding. The water-filtering functional layer material is first placed in a stainless steel mold (200*100*50mm), and then the water-permeable surface layer material is added to the mold to open the concrete. The vibrating table vibrates, and at the same time, the universal press is turned on to apply a pressure of 1.5MPa for 45s. After 2 hours, the mold and the uncured composite material are turned over together, and no special maintenance is required for curing at room temperature. After demoulding after 24 hours, the filter functional material of the microporous filter surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com