Novel landing-gear-drop-test driving rotating device and test method

A landing gear and test belt technology, applied in the field of aeronautical engineering, can solve the problems of not meeting the requirements of belt rotation, affecting the stability of belt rotation, and vibration of the motor, and achieving the effects of simple structure, convenient height adjustment and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

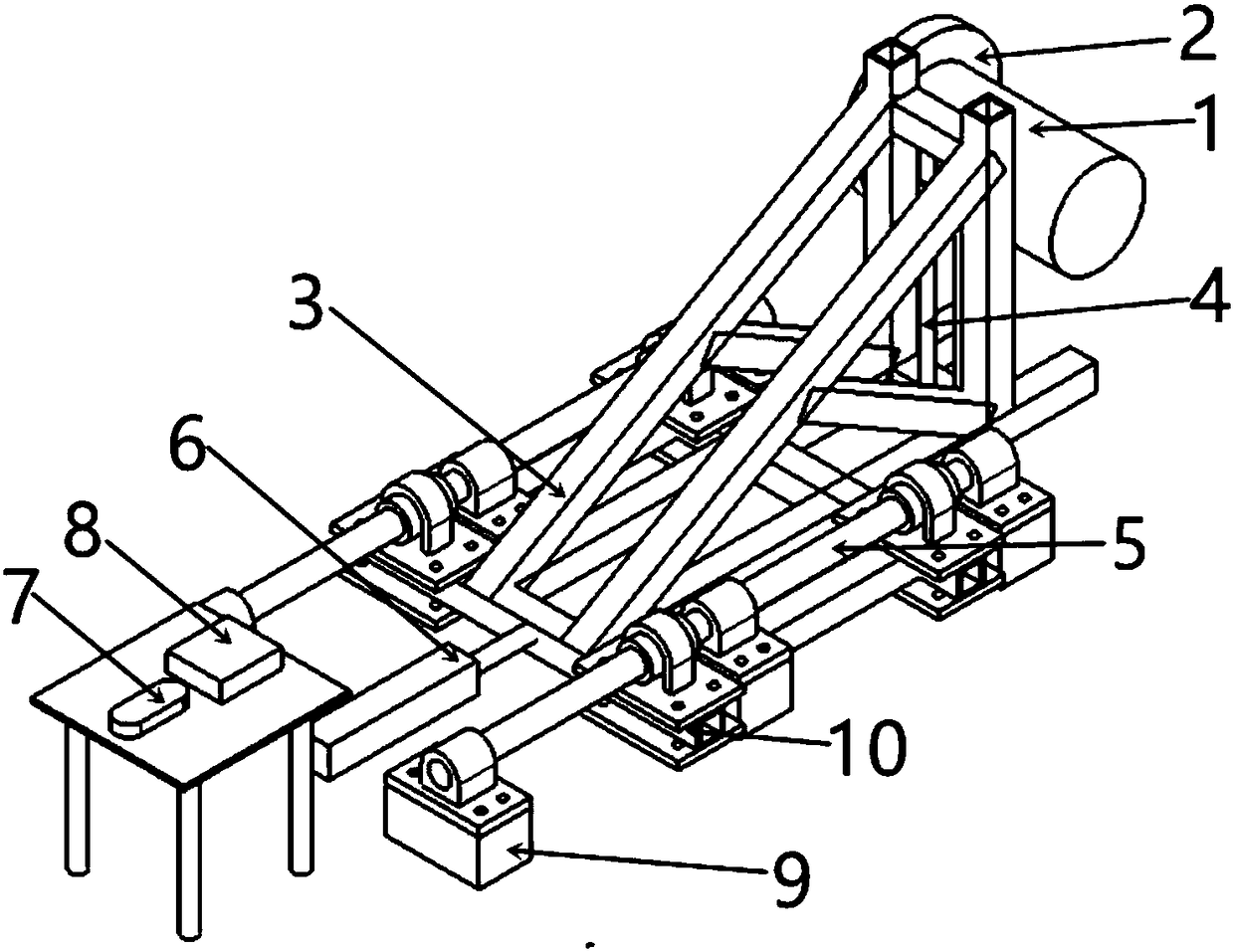

[0021] The patent will be further described below in conjunction with the accompanying drawings and specific examples, but not as a limitation of the patent.

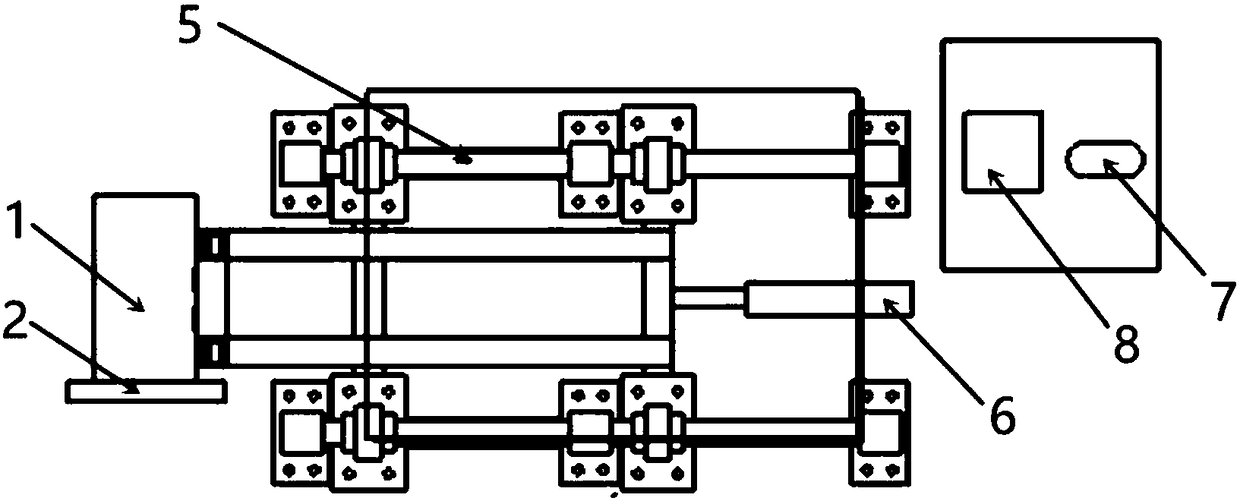

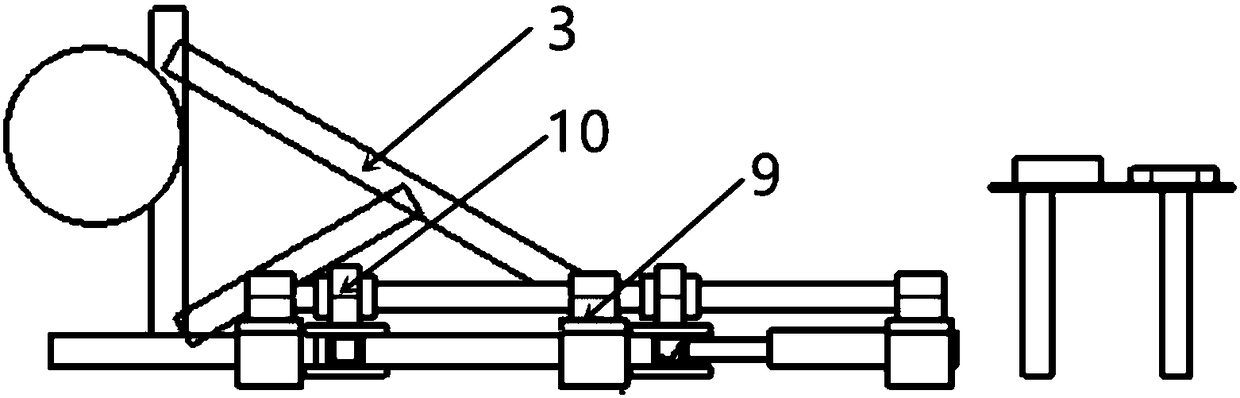

[0022] A novel undercarriage drop test belt rotating device provided by the present invention, the device to be rotated includes a motor 1, a friction wheel 2, a lifting screw 3, a support stand 4, a sliding guide rail 5, an actuator 6 and an air pressure adjustment Valve 7, wherein, described sliding guide rail 5 is provided in pairs, is fixed with support stand 4 in its inner side; Described support stand 4 is fixed with slide guide rail 5 as a whole, and slides on slide guide rail 5; A lifting screw 3 is arranged in the frame 4, and the direction of the lifting screw 3 is approximately perpendicular to the direction of the sliding guide rail 4; a motor 1 is provided at the end of the lifting screw 3 away from the sliding guide rail, and a friction wheel 2 is connected to the motor;

[0023] One end of the support sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com