Manufacturing method of sealing ring used for fuel-tank caps

A manufacturing process and sealing ring technology, which is applied in the field of manufacturing process of sealing rings for fuel caps, can solve the problems such as failure of the rubber ring to reach predetermined technical indicators, cracks and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

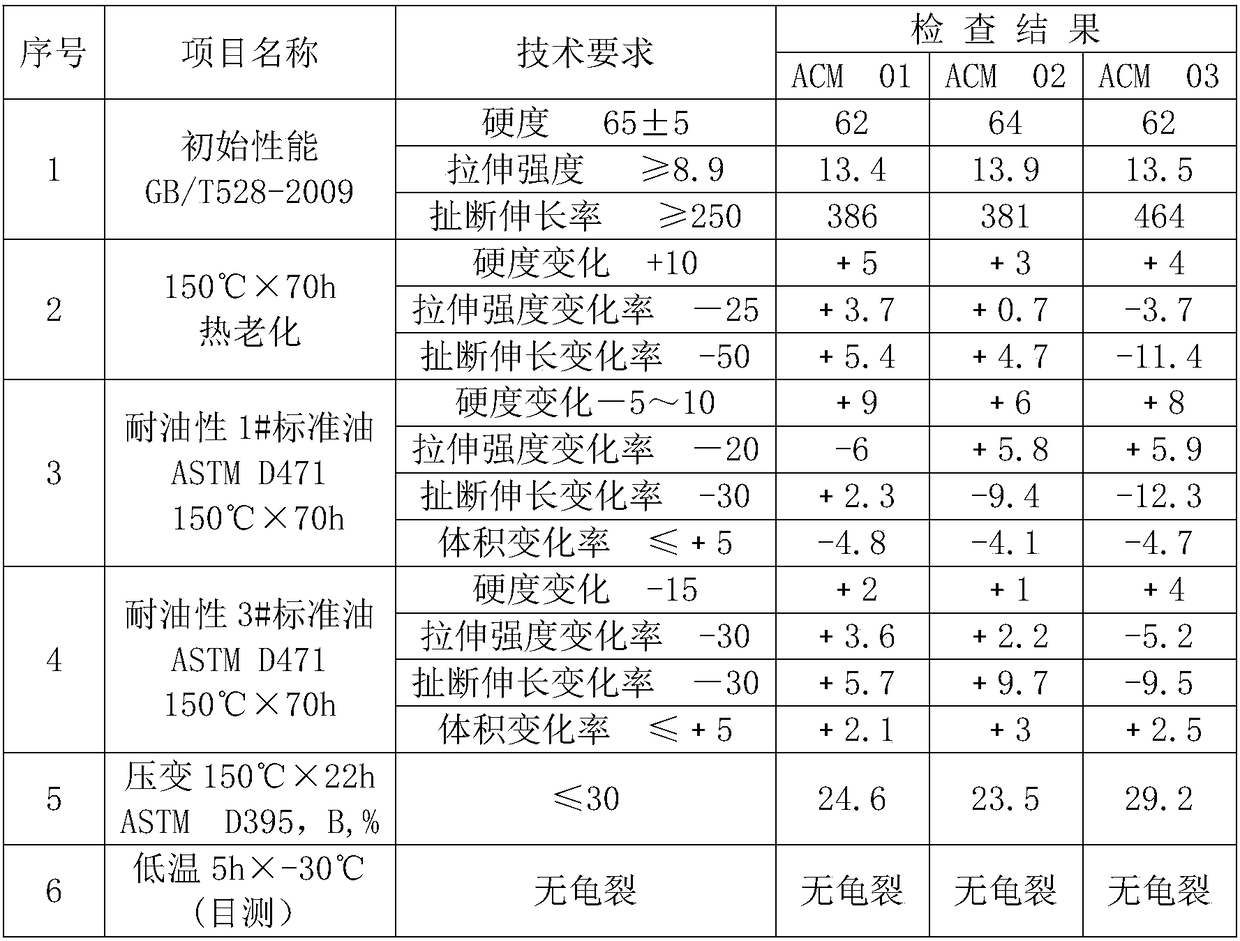

Examples

Embodiment 1

[0032] Embodiment 1 of the present invention: a kind of manufacturing process of oil filler cap seal ring, comprises the following steps:

[0033] First, weigh the formula raw materials according to the following parts by weight, acrylate rubber 90, fluorine rubber 10, high wear-resistant carbon black 25-35, fast extruded carbon black 15-25, plasticizer 8-11, anti-scorch agent 0.1-25 0.5, paraffin 0.8-1.5, anti-aging agent 4.5-5.5, sulfur 0.3-1, potassium stearate 0.5-0.7, sodium stearate 3.5-4. The type of the anti-aging agent is MC445 and grade 1 RD, and the weight part of the MC445 type antioxidant is 2.4-3.6. The weight part of the first-grade RD type antioxidant is 0.9-1.1.

[0034] The model of acrylate rubber in the present embodiment is AR-100, the model of fluorine rubber is DS2602, the model of high wear-resistant carbon black is N330, the model of fast extrusion carbon black is N550, and the model of plasticizer is THIOKOL TP- 95. The model of the anti-scorch agent...

Embodiment 2

[0040] Embodiment 2: a kind of manufacturing process of oil filler cap sealing ring, comprises the following steps:

[0041] First, weigh the formula raw materials according to the following parts by weight, acrylate rubber 89.8, fluorine rubber 9.8, high wear-resistant carbon black 24.8, fast extruded carbon black 14.8, plasticizer 7.8, anti-scorch agent 0.2, paraffin wax 0.7, anti-aging agent 4.4 , sulfur 0.2, potassium stearate 0.4, sodium stearate 3.4. The type of the anti-aging agent is MC445 and grade 1 RD, and the weight part of the MC445 type antioxidant is 2.4-3.6. The weight part of the first-grade RD type antioxidant is 0.9-1.1.

[0042] The model of acrylate rubber in the present embodiment is AR-100, the model of fluorine rubber is DS2602, the model of high wear-resistant carbon black is N330, the model of fast extrusion carbon black is N550, and the model of plasticizer is THIOKOL TP- 95. The model of the anti-scorch agent is CTP, the model of paraffin is OK1900...

Embodiment 3

[0048] Embodiment 3: a kind of manufacturing process of sealing ring for refueling cap, comprises the following steps:

[0049] First, weigh the formula raw materials according to the following parts by weight, acrylate rubber 90.2, fluororubber 10.2, high wear-resistant carbon black 35.2, fast extruded carbon black 25.2, plasticizer 11.2, anti-scorch agent 0.6, paraffin wax 1.6, anti-aging agent 5.6 , sulfur 0.9, potassium stearate 0.6, sodium stearate 4.1. The type of the anti-aging agent is MC445 and grade 1 RD, and the weight part of the MC445 type antioxidant is 2.4-3.6. The weight part of the first-grade RD type antioxidant is 0.9-1.1.

[0050] The model of acrylate rubber in the present embodiment is AR-100, the model of fluorine rubber is DS2602, the model of high wear-resistant carbon black is N330, the model of fast extrusion carbon black is N550, and the model of plasticizer is THIOKOL TP- 95. The model of the anti-scorch agent is CTP, the model of paraffin is OK19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com