Weather-resistant PC/polyester alloy material as well as preparation method and application thereof

A polyester alloy and weather-resistant technology, applied in the field of weather-resistant PC/polyester alloy materials and their preparation, can solve the problems of failing to meet the aging of xenon lamp, alternating heat and cold test and fatigue test, failing to meet the weather-resistant conditions of exterior decoration, etc. Achieve high weather resistance and improve the effect of low temperature impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

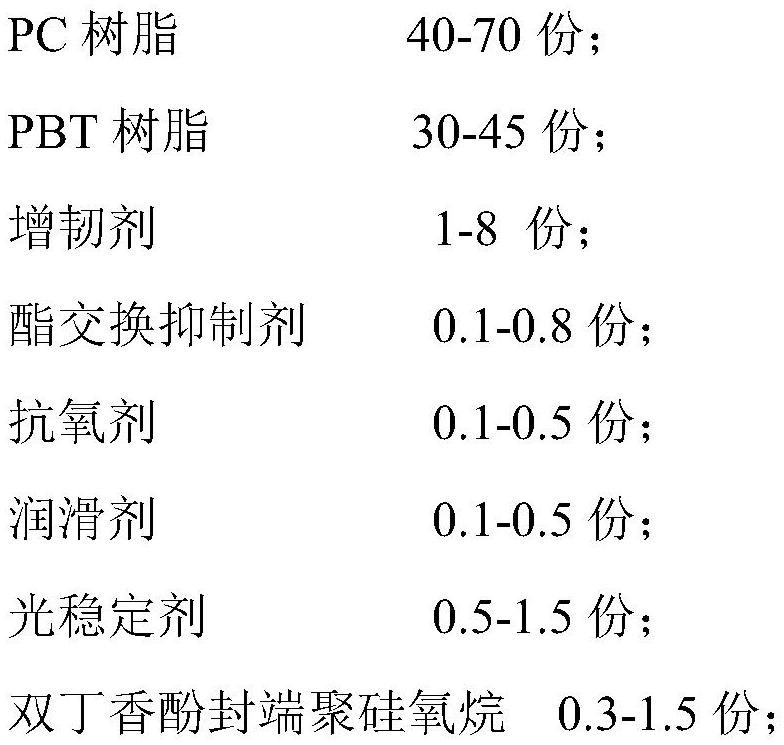

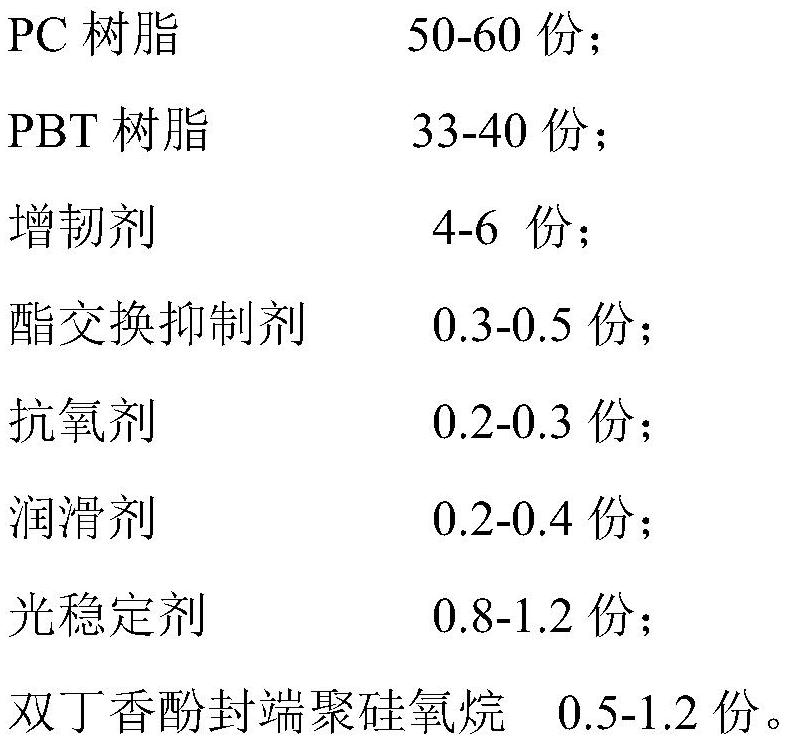

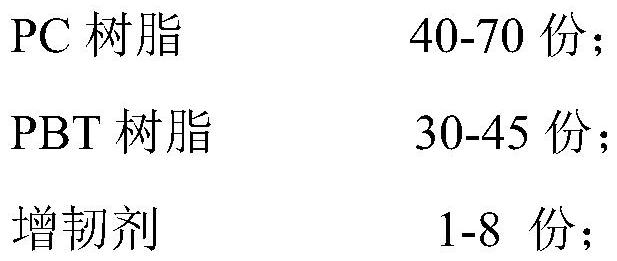

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific embodiments. The raw materials in the examples and comparative examples can be obtained commercially or can be prepared by known methods. In addition, "part" and "%" in this specification represent "mass part" and "mass %", respectively, unless otherwise specified.

[0041] The manufacturers and trade marks of the raw materials used in the following examples and comparative examples are as follows:

[0042] 1. PC resin:

[0043] PC resin A: Bisphenol A type, PC A2200, Taiwan, China;

[0044] PC resin B: transesterification method, WY-111BR, Lihuayiweiyuan;

[0045] 2. PBT resin:

[0046] PBT resin 1: intrinsic viscosity 1.02dl / g, PBT GX121, Sinopec Yizheng Chemical Fiber;

[0047] PBT resin 2: intrinsic viscosity 0.86dl / g, PBT 1084, Nantong Xingchen;

[0048] 3. Dieugenol-terminated polysiloxane: O-S10, Guangzhou Huisil Composite Materials Co., Ltd.;

[0049] 4. Silicone toughening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dimension change | aaaaa | aaaaa |

| dimension change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com