Prefabricated self-restoring concrete filled steel tube composite joint, installation method and structural system

A technology of steel pipe concrete and combined joints, which is applied in the direction of building construction and construction, can solve problems that need to be researched and developed, and achieve the effect of saving economic costs and time costs and increasing joint stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

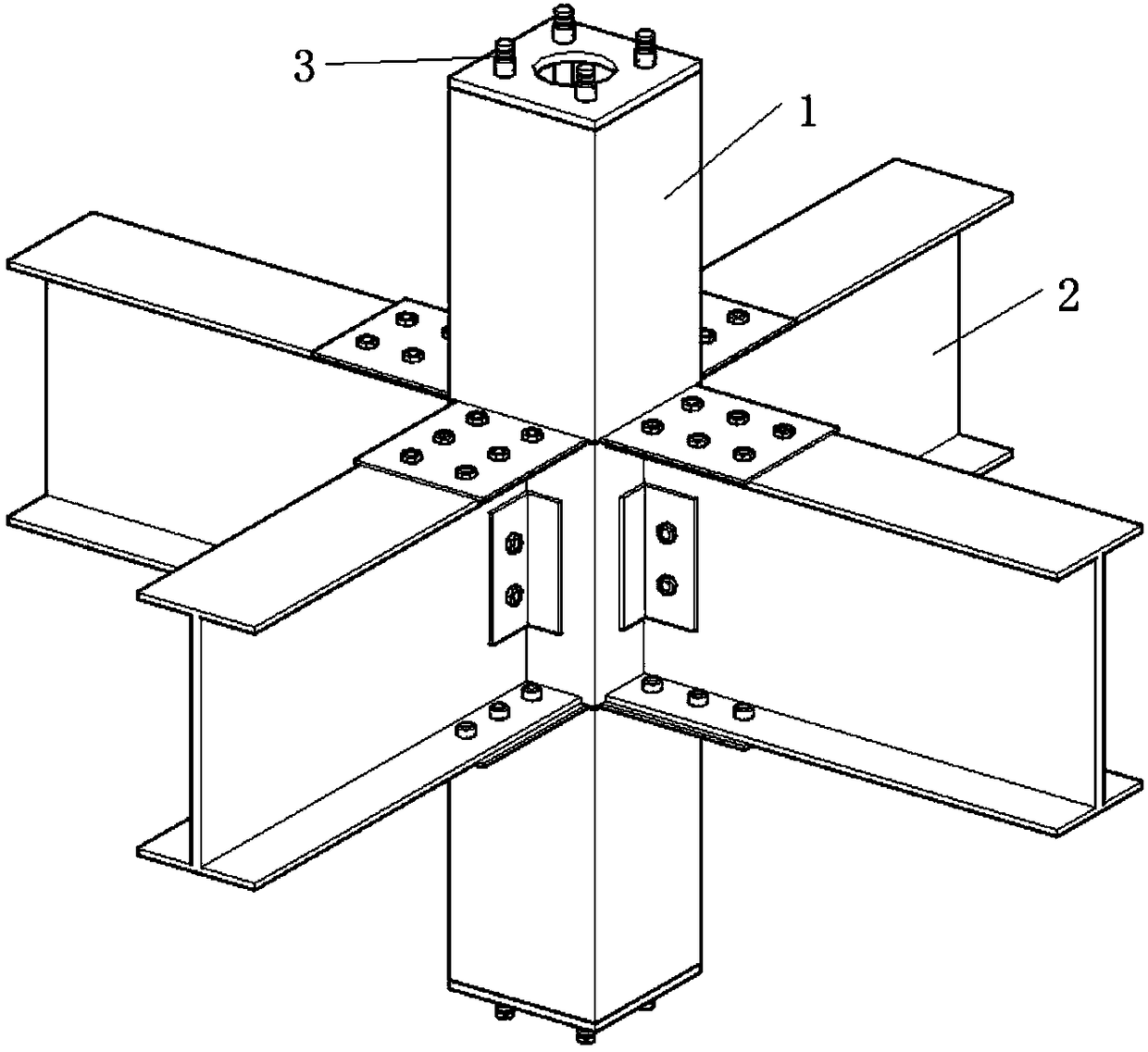

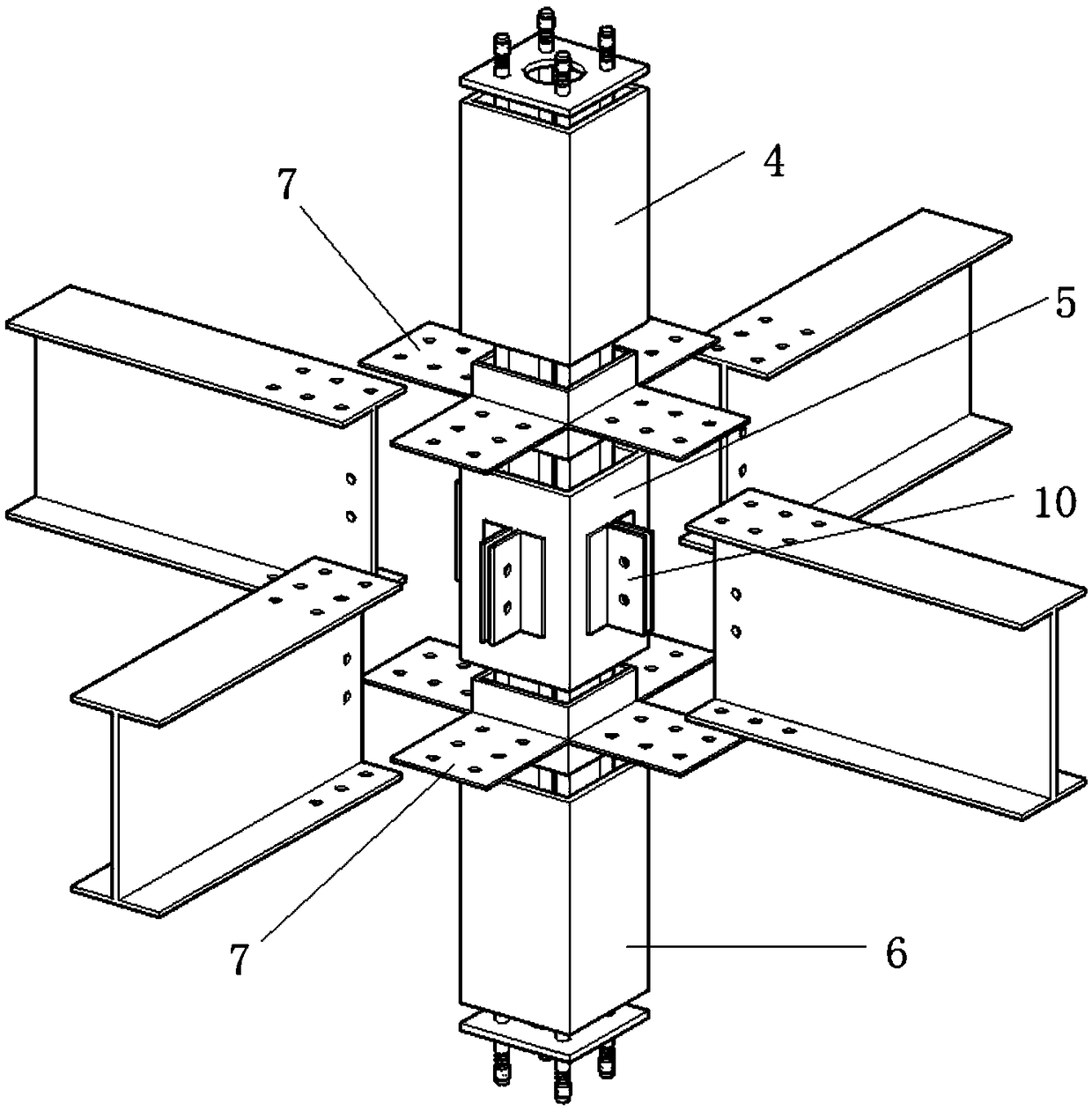

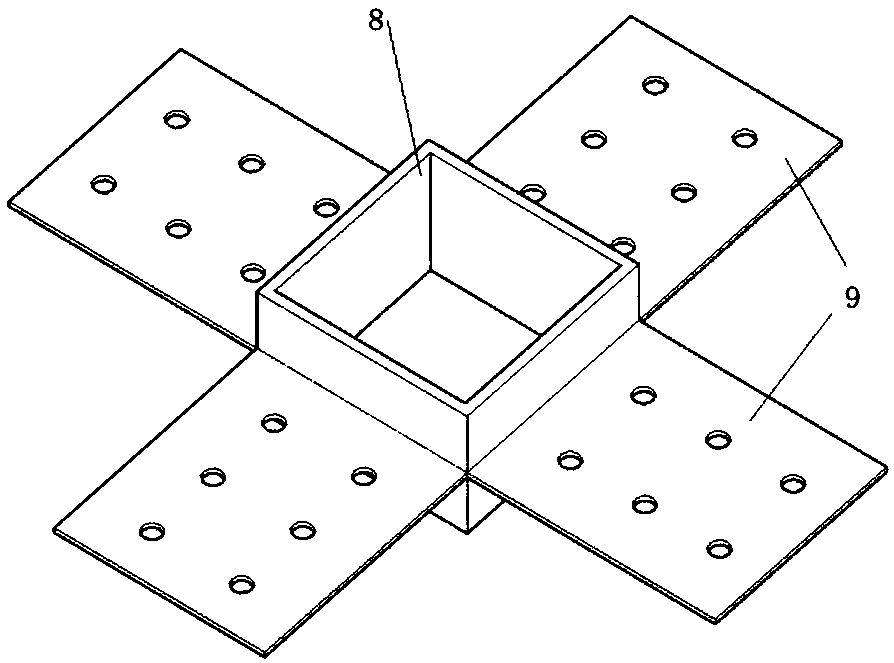

[0050] Such as figure 1 with figure 2 As shown, the assembled self-recovering steel pipe concrete composite node of the present invention includes a square steel pipe column I1 and four H-shaped steel beams 2, the steel bar 3 runs through the square steel pipe column I, and the square steel pipe column I includes the upper steel pipe column 4, The central steel pipe column 5 and the lower steel pipe column 6, the upper steel pipe column and the central steel pipe column, and the central steel pipe column and the lower steel pipe column are all connected by sleeve connectors 7;

[0051] The upper end of the upper steel pipe column and the lower end of the lower steel pipe column are all welded with a steel bar fixing plate 12, and the center of the steel bar fixing plate is provided with a through hole 11 for pouring concrete. The steel bars pass through the steel bar fixing plate at the upper end of the steel pipe column in the upper section, the square steel pipe column I a...

Embodiment 2

[0066] Such as Figure 11 , 12 As shown, the difference between this embodiment and Embodiment 1 is that the steel pipe column at the beam-column node in the middle adopts a sleeve-type steel pipe column, and the sleeve-type steel pipe column includes a square steel pipe column II17 and a round steel pipe column 18, and the round steel pipe column Set inside the square steel pipe column II; the upper and lower layers of sleeve-type steel pipe columns are connected by double-sleeve connectors, which include square outer sleeves 19 and circular inner sleeves 20, and square outer sleeves. The sleeve is arranged outside the square steel pipe column II, the circular inner sleeve is arranged inside the round steel pipe column, the lower end of the upper square steel pipe column II, the upper end of the lower square steel pipe column II, the lower end of the upper round steel pipe column and the upper end of the lower round steel pipe column Bolt holes, the square outer sleeve and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com