A method for rapid on-site commissioning evaluation of mobile transformers

An evaluation method and transformer technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of non-compliance, flexibility, quickness, strong mobility, long time consumption, and inability to quickly put into operation on site, so as to reduce the cost of test equipment and time cost , Inspection and test item reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] During the transportation of a mobile transformer that has been used for a long time, it was monitored that the amplitude of the vertical shock vibration acceleration was 5.5g / m once. 2 , exceeding the technical requirement value 3g / m given by the manufacturer in advance 2 .

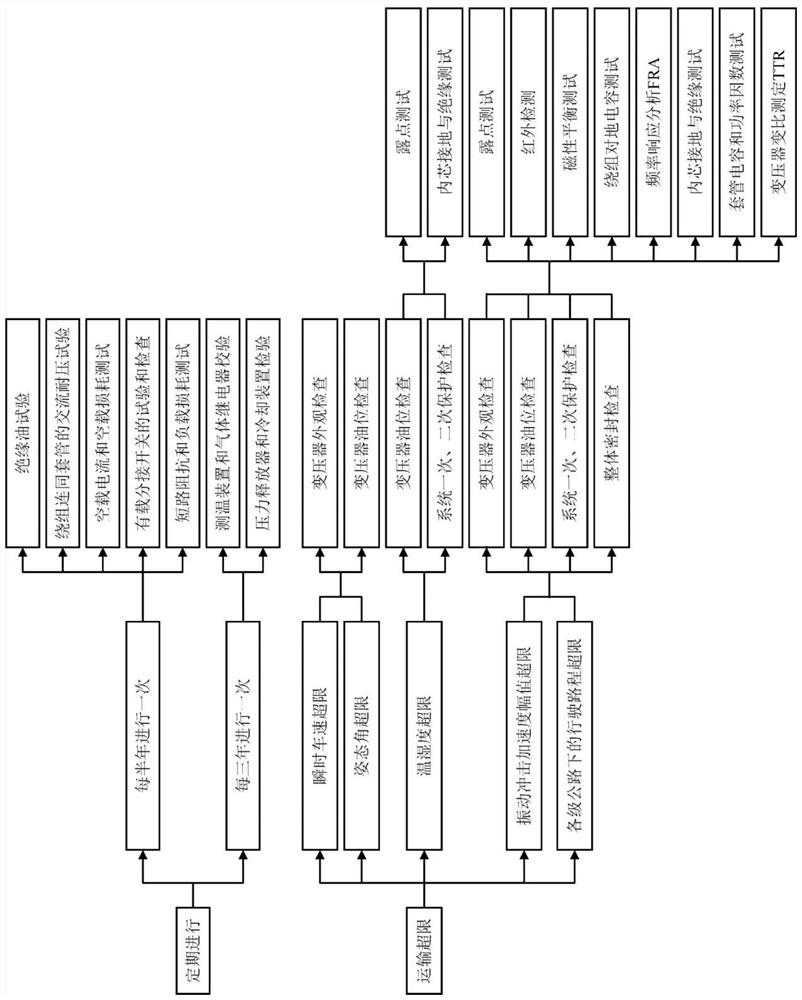

[0026] according to figure 1 The process requirements shown, after being transported to the site, the following inspections and tests should be carried out immediately:

[0027] Transformer appearance inspection, transformer oil level inspection, system primary and secondary protection inspection, overall sealing inspection, and then conduct dew point test, infrared detection, magnetic balance test, winding capacitance test to ground, frequency response analysis FRA, inner core grounding and insulation test , bushing capacitance and power factor test and transformer ratio determination TTR.

[0028] In the frequency response analysis FRA, using the transformer winding deformation tester, there ...

Embodiment 2

[0030] A mobile transformer that has been used for a long time has been in an idle state for half a year since the last regular inspection. according to figure 1 According to the requirements of the process shown, the items that need to be completed every six months: insulating oil test, AC withstand voltage test of winding and bushing, no-load current and no-load loss test, test and inspection of on-load tap changer and short-circuit impedance and Load loss test.

[0031] After testing, in the insulating oil test, using the inspection method specified in the electric power standard DL 429.1-91, if impurities and suspended matter are found in its appearance, it is necessary to stop using the mobile transformer immediately, and perform maintenance on site or return to the factory .

Embodiment 3

[0033] A mobile transformer that has been used for a long time does not have any physical quantity exceeding the limit during transportation, and the items of regular inspection or test all meet the technical requirements or operating procedures. According to figure 1 The process requirements shown meet the conditions for rapid commissioning and can be put into operation directly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com