Full automatic glass slide smear dyeing machine

A slide and dyeing machine technology, applied in the field of medical instruments, can solve the problems of unguaranteed dyeing effect and quality, and high labor cost, so as to achieve the effect of ensuring effect and quality, reducing labor cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

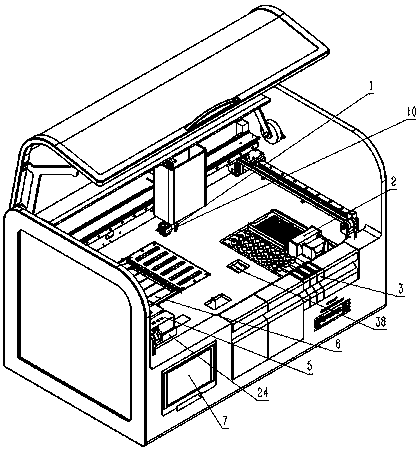

[0024] Such as figure 1 As shown, this embodiment includes a slide and Tip extraction module 1, a slide and Tip rack 2, a sample rack 3, a label peeling module 38, a finished slide bin module 5, a slide staining module 6, and a control module 7 .

[0025] Among them, slide and Tip head extracting module 1 is used for grasping, moving slide glass or coverslip, and grasping, moving Tip head, dropping sample; Slide and Tip head frame 2 is used for placing slide glass, Cover glass and Tip head; sample rack 3 is used to place sample tubes; label peeling module 38 is used to peel labels from label paper; finished slide storage module 5 is used to store processed wet slides and stained slides; slides The dyeing module 6 is used for dyeing; the control module 7 is used for controlling each electrical module to work in an orderly manner.

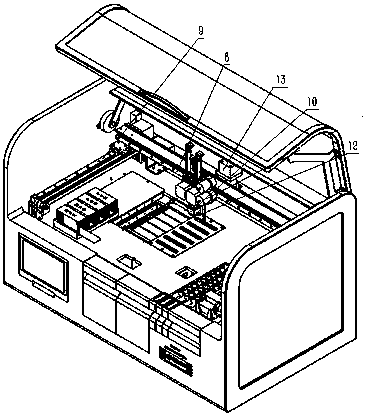

[0026] Such as figure 2 Shown is the slide and Tip head extracting module in this embodiment, the slide and Tip head extracting module includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com