Process defect risk analysis method based on procedure association relationship

A technology for process defect and risk analysis, which is applied in the field of process defect risk analysis based on process correlation, and can solve problems such as difficult characterization of process defects

- Summary

- Abstract

- Description

- Claims

- Application Information

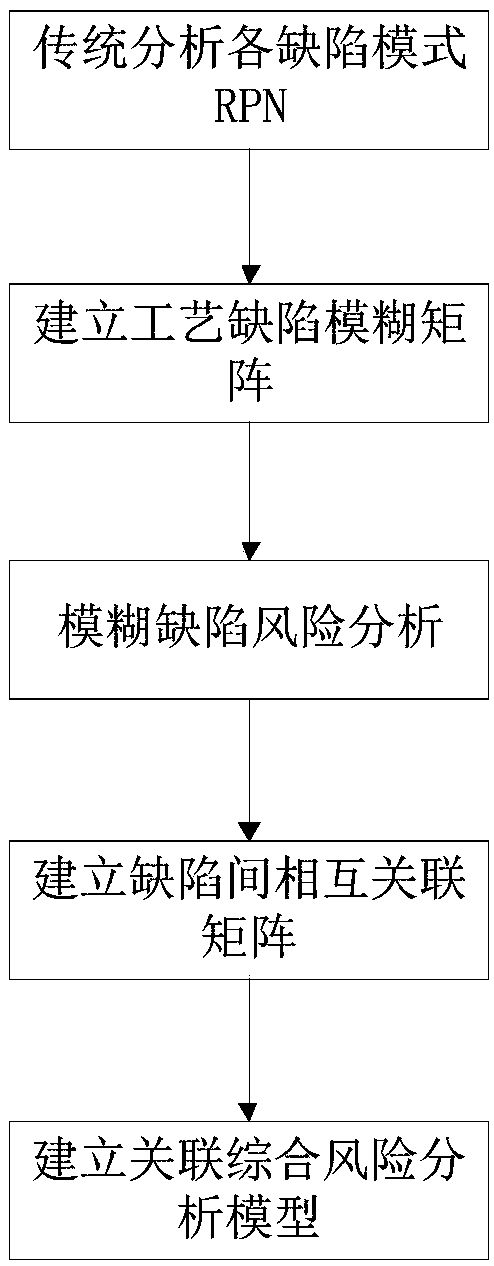

AI Technical Summary

Problems solved by technology

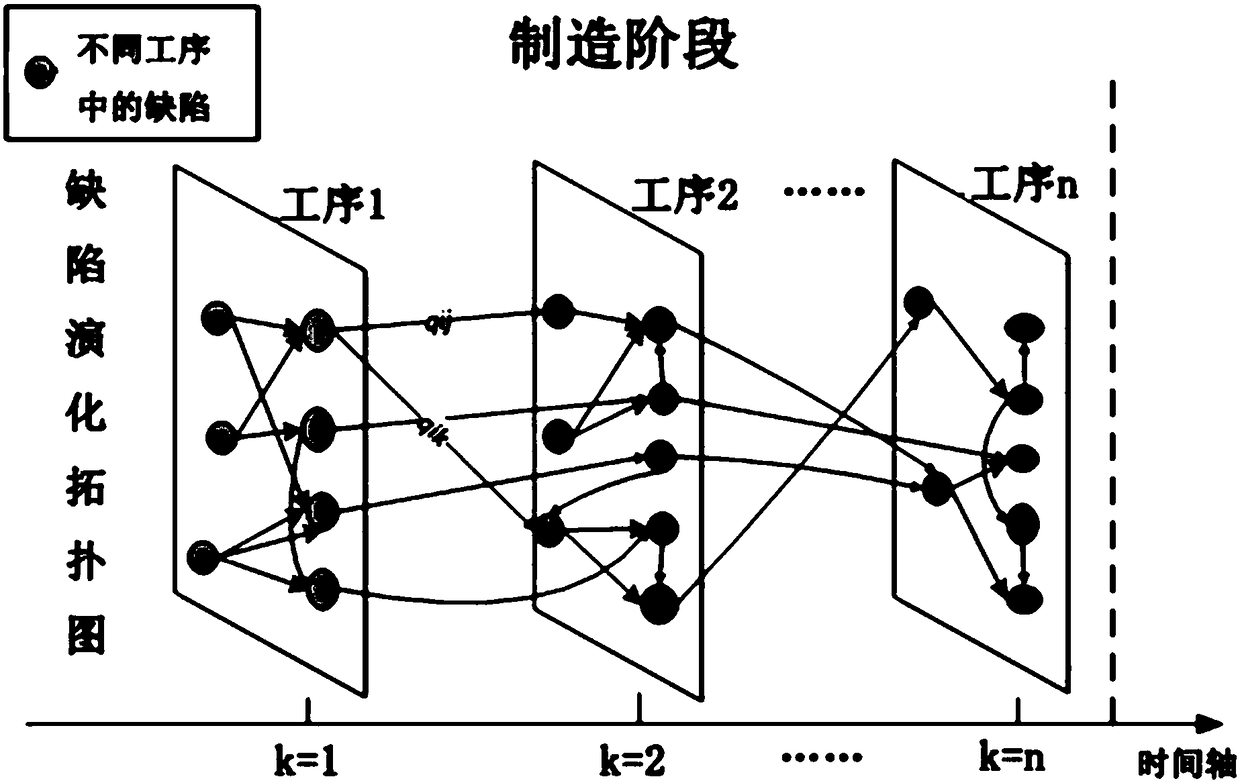

Method used

Image

Examples

Embodiment 1

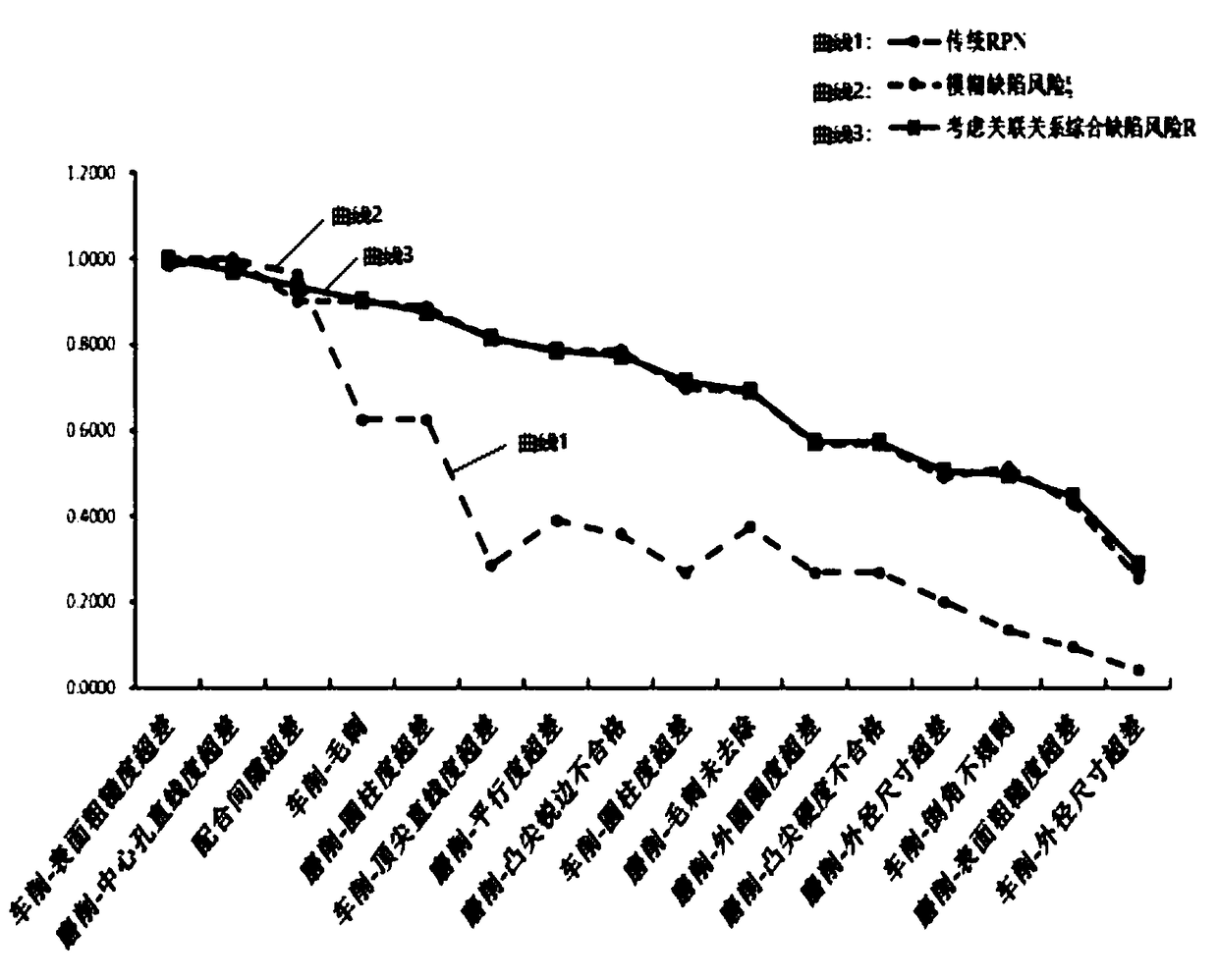

[0114] Taking the three processes of turning the outer circle of the valve core, grinding the outer circle and pairing the grinding as an example, the process defect analysis is carried out and compared with the RPN value in the PFMEA analysis method.

[0115] Optionally, in this embodiment, the specific relative risk calculation process is omitted, and some relevant analysis results are excerpted to obtain Table 2, which is the traditional FPMEA analysis table of the car-grinding-assembly process.

[0116] Table 2

[0117]

[0118]

[0119]

[0120] In the table, GX represents the process, and QX represents the defect.

[0121] The present invention adopts the analytic hierarchy process to distribute the weights of the evaluation indicators of the three dimensions of defect occurrence degree, detection degree and severity degree. Based on expert experience, the weight matrix is determined as ω=[0.4,0.25,0.35], and the directed graph of process defects is establishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com