Lithium battery safety valve opening pressure finite element modeling method

A technology of safety valve opening and modeling method, which is applied in the field of finite element modeling to analyze the opening pressure of lithium battery safety valve, and achieves the effect of reducing the cost of trial production and experiment and filling the technical gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

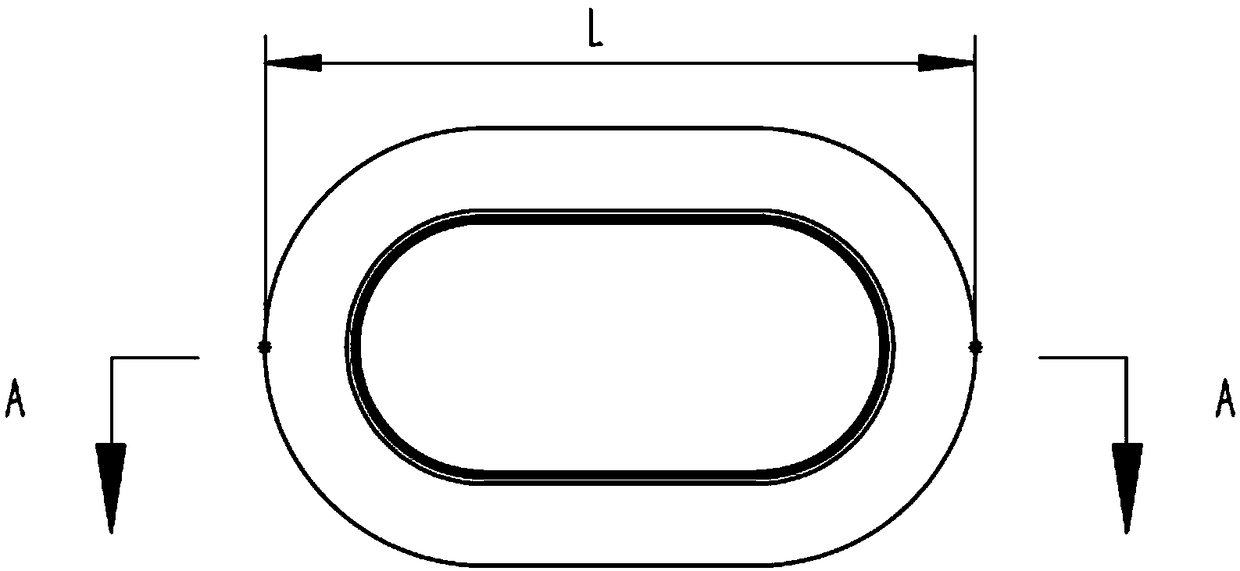

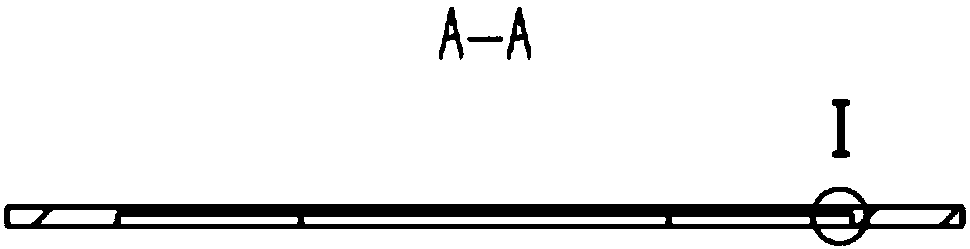

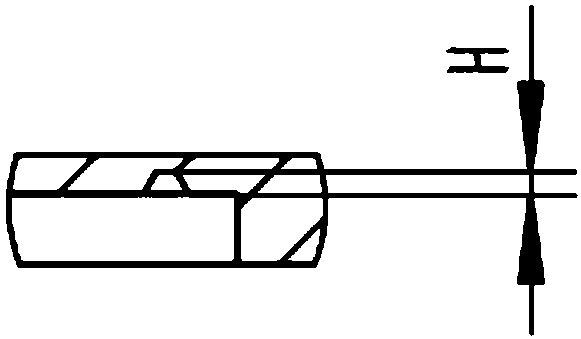

[0045]The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0046] Such as Figure 1-Figure 7 As shown, a finite element modeling method for the opening pressure of a lithium battery safety valve of the present invention comprises the following steps:

[0047] Step 1: Creation and delivery of parametric geometric models, including,

[0048] Step 1.1: Determine the characteristic parameters of the product, the characteristic parameters include thickness, length, outer diameter, inner diameter and notch depth, use each characteristic parameter as input, and use CATIA three-dimensional modeling software to establish a parameterized lithium battery safety valve Three-dimensional solid model; among them, the notch depth is a key parameter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com