Virtual bench model for aluminum alloy rim impact test

An impact test, aluminum alloy technology, applied in the direction of impact test, machine/structural component test, measurement device, etc., can solve the problem of inability to effectively determine impact dangerous parts, inability to intuitively feedback impact risk points, and simulation results that are not consistent with the test. standard and other problems, to achieve the effect of speeding up the time of product launch, improving the efficiency of design and development, and reducing the cost of mold development and mold repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

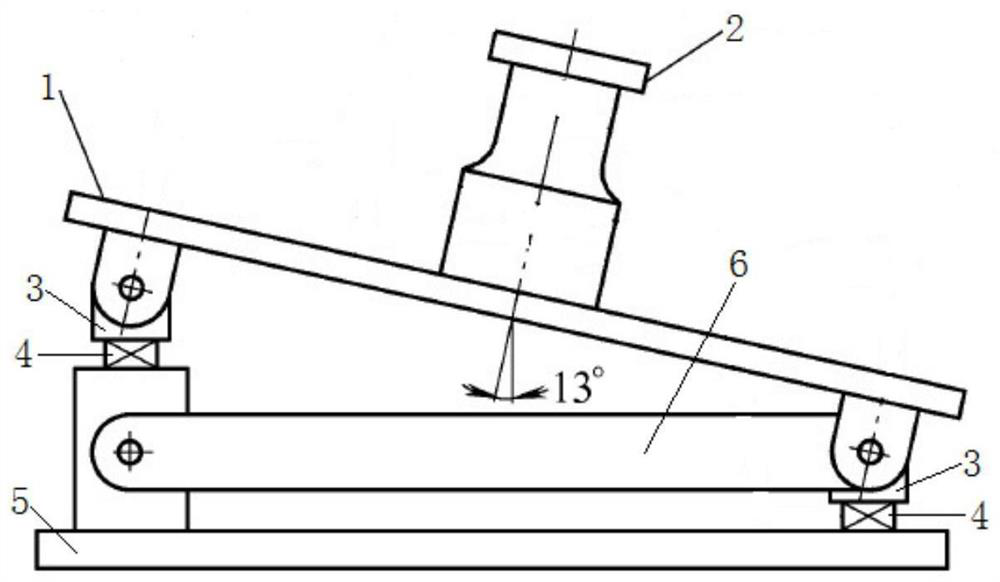

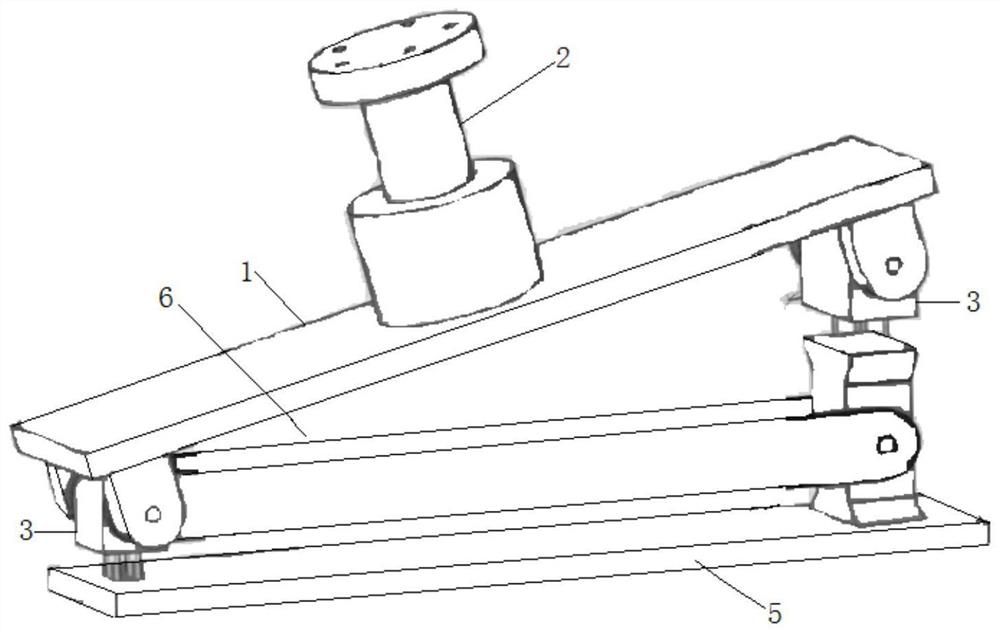

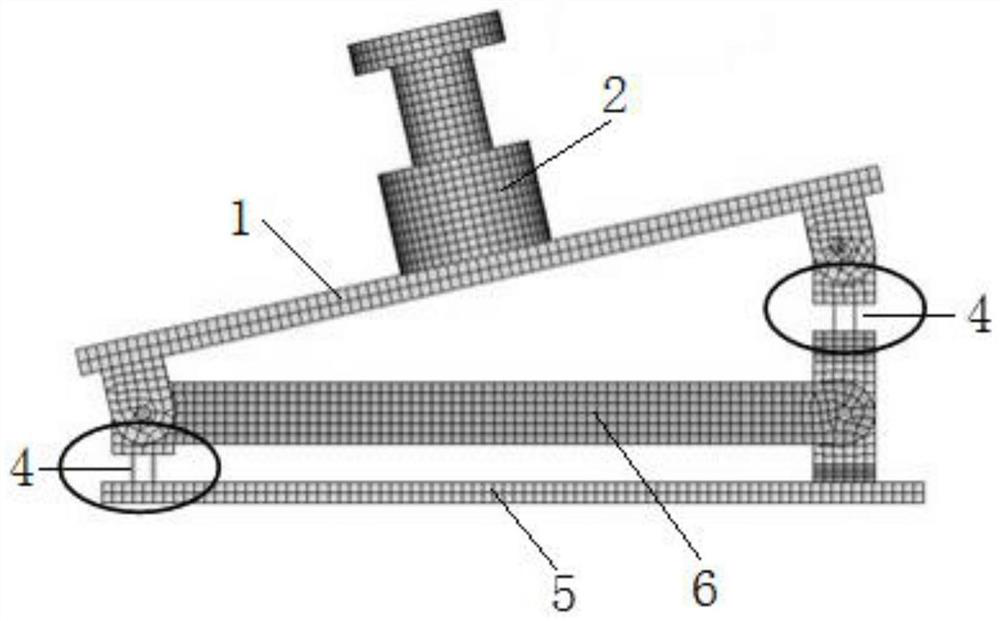

[0051] refer to Figure 1 to Figure 17 As shown, the aluminum alloy rim impact test virtual bench model in an embodiment provided by the present invention includes the impact test bench finite element model and the wheel rim 9 finite element model;

[0052] The finite element model of the impact test bench includes a steel plate beam 1, a mounting plate 2 and a base 3. There are two rubber bearings 4 on the bottom plate 5. The steel plate beam 1 is arranged in an inclined manner. 3 are hinged, the two bases 3 are respectively connected with two rubber bearings 4, the mounting plate 2 is installed on the steel plate beam 1, and the central axis of the mounting plate 2 is perpendicular to the mounting surface of the steel plate beam 1; the finite element model of the rim 9 is passed The bolts are rigidly connected to the mounting plate 2 of the finite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com