Dustproof door of high voltage capacitor cabinet

A technology for high-voltage capacitors and cabinet doors, which is applied in the cooling/ventilation of substations/switchgears, electrical components, substations/distribution device shells, etc., which can solve the problems of easy dust ingress in windows, and ensure heat dissipation and dust prevention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

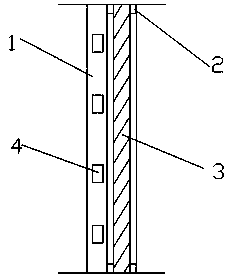

[0010] like Figure 1~2 The dust-proof door of a high-voltage capacitor cabinet shown includes a cabinet door 1, and a pair of parallel channels 2 are arranged on the inner side of the cabinet door 1, and a dust-proof net 3 is embedded in the channel 2. The cabinet door 1 is evenly provided with a number of vents 4; when the cabinet door 1 is in the open state, the dust-proof net 3 can be pulled out of the channel 2 to realize separation from the cabinet door 1; the end of the dust-proof net 3 is provided with a protrusion 4. There is a groove on the inner side of the channel corresponding to the protrusion, and the protrusion can be snapped into the groove; the channel is fixed on the inner side of the cabinet door by bolts or glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com