Husking pretreatment device of husker

The technology of a pretreatment device and a peeling machine is applied in the directions of harvesters, agricultural machinery and implements, applications, etc., and can solve the problems of poor peeling effect and no corn peeling pretreatment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

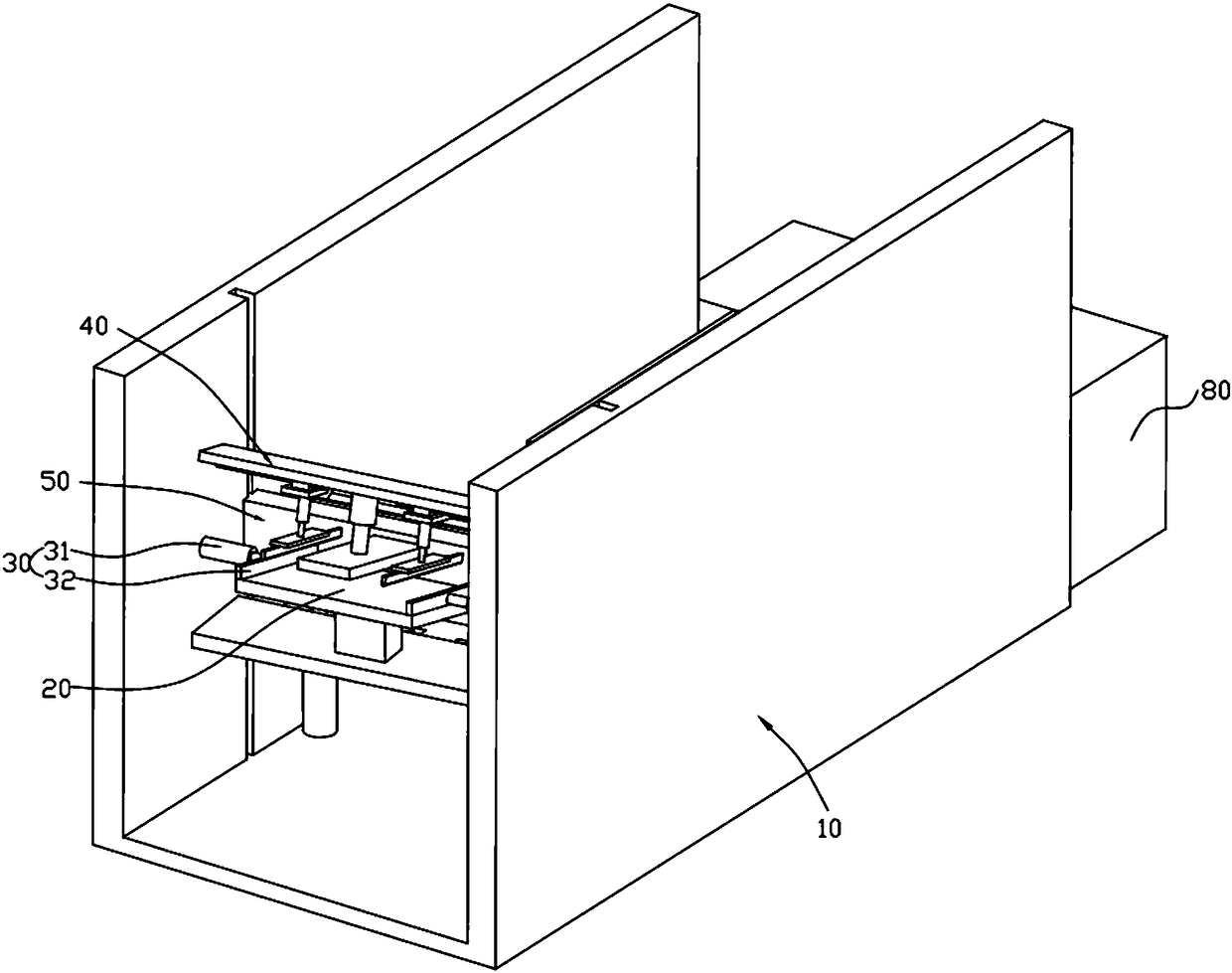

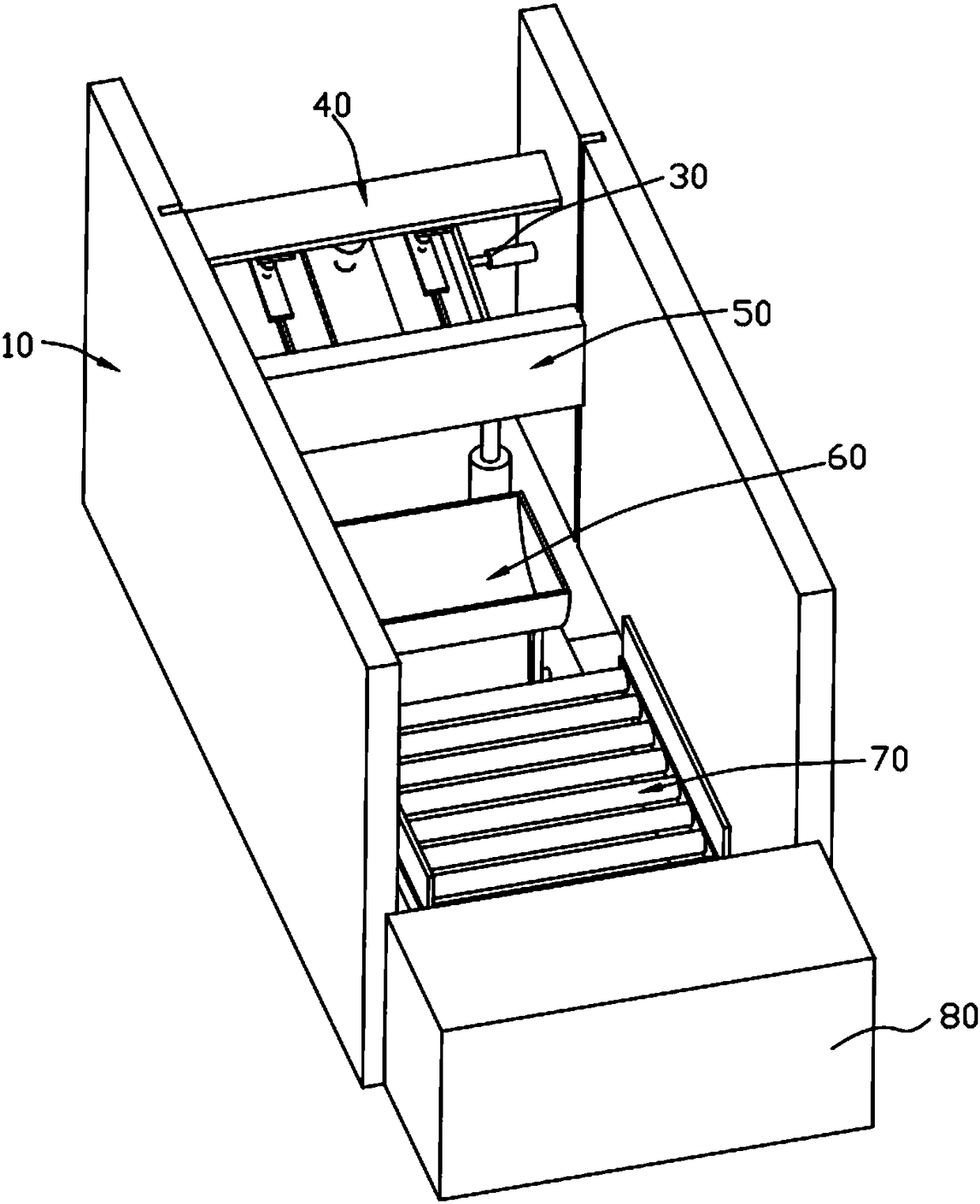

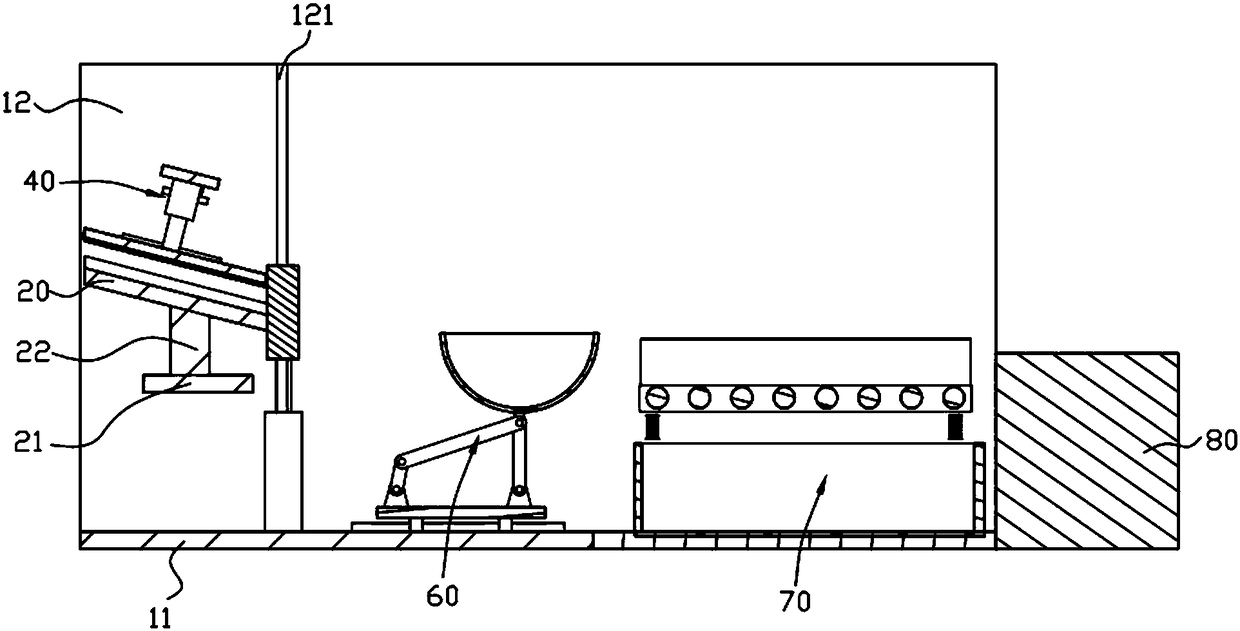

[0024] Such as Figure 1 to Figure 3 As shown, the present invention provides a peeling pretreatment device of a peeling machine, comprising: a frame 10, which includes a bottom plate 11 and a pair of side plates 12 symmetrically arranged on the both sides of the bottom plate 11, the bottom plate 11 and the side plate 12 are surrounded to form an accommodating area; a bearing plate 20 obliquely arranged in the accommodating area of the frame 10; installed in the accommodating area of the frame 10 and located in the Carrying plate 20 both sides are used to push a pair of pushing plate units 30 of corn ear end; One is installed in the accommodating area of described frame 10 and is positioned at the cutting unit 40 above described carrying plate 20; A baffle unit 50 loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com