Coffee drink and preparation method thereof

A technology for coffee and beverages, applied in the field of coffee beverages and their preparation, can solve the problems of serious homogeneity, single flavor and single selling point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

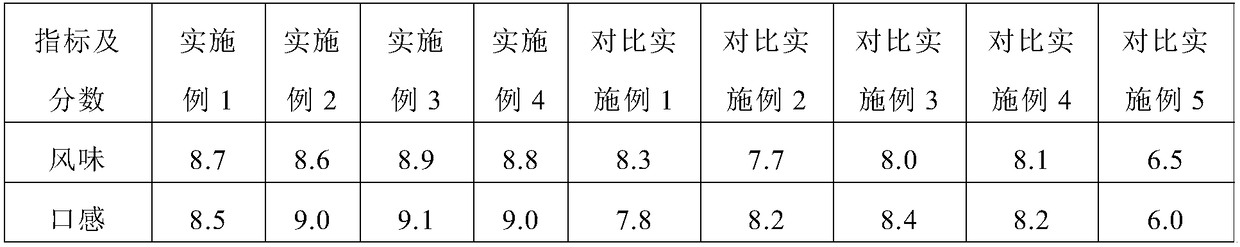

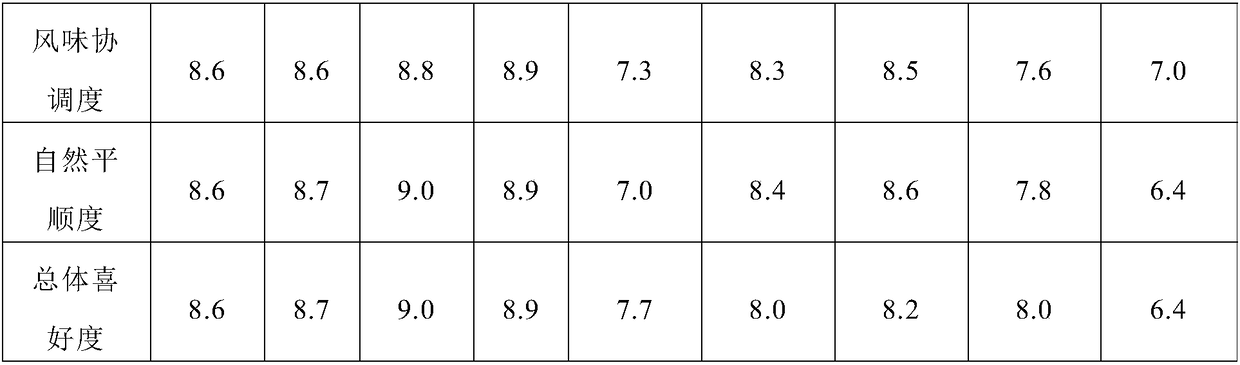

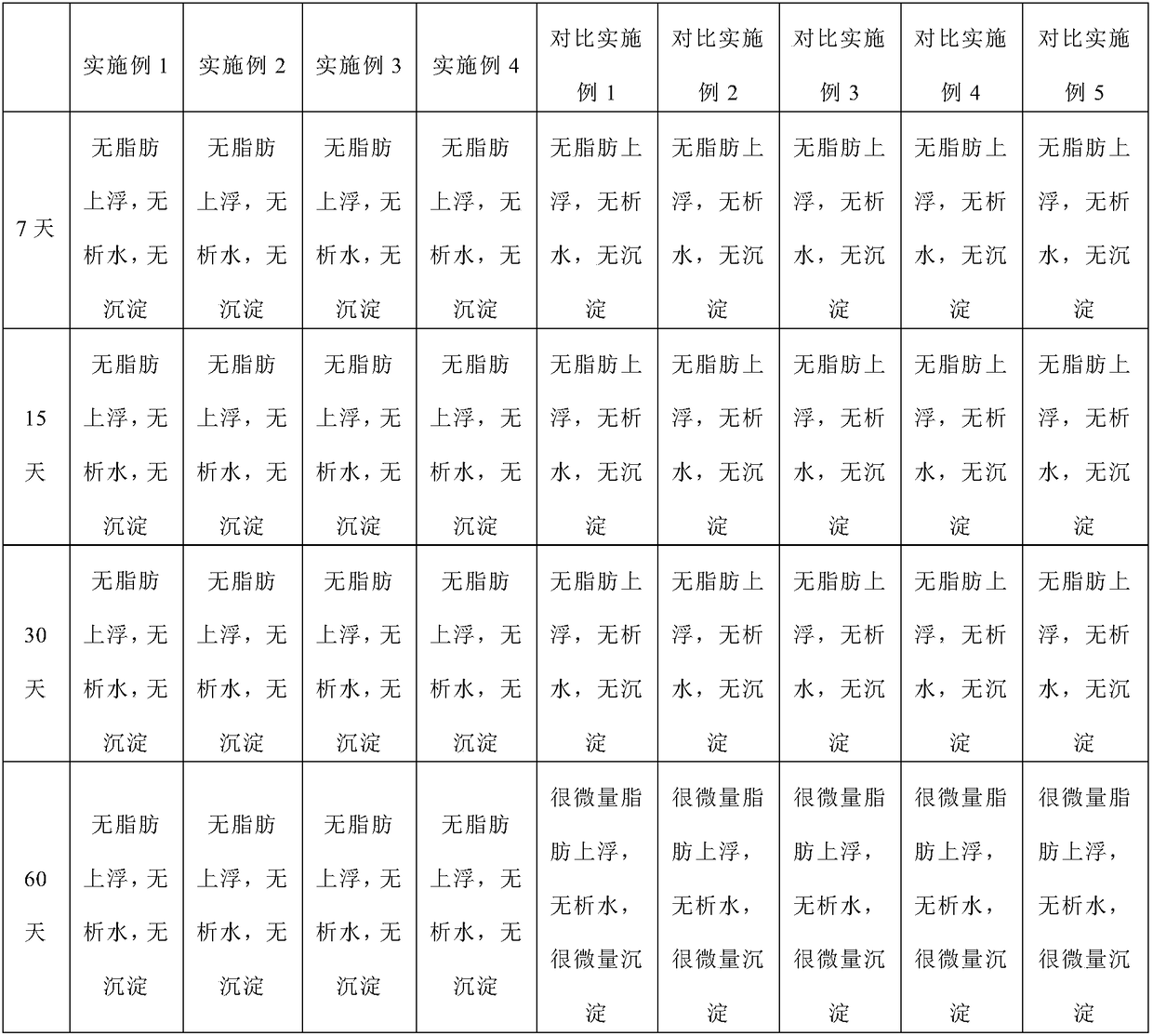

Examples

Embodiment 1

[0075] 1. Recipe

[0076] Milk: 100 kg;

[0077] Coffee: 3 kg;

[0078] Glucose: 50 kg;

[0079] Cheese: 20 kg;

[0080] Sweetener: 30 kg;

[0081] Cream: 50 kg;

[0082] Stabilizer: 20 kg;

[0083] Emulsifier: 0.2 kg;

[0084] Acidity regulator: 0.1 kg;

[0085] Water: make up to 1000 kg.

[0086] 2. Preparation method

[0087] 2.1 Milk and glucose were mixed, heated to 85°C, stirred and dissolved for 5 minutes, left to stand for insulation browning, the browning temperature was 85°C, the holding time was 3.5 hours, and cooled to obtain a milk base;

[0088] 2.2 Dissolve the coffee with an appropriate amount of water, stir and dissolve for 10-30 minutes and mix evenly, add an appropriate amount of acidity regulator, stir and mix evenly to obtain a coffee base with a pH value of 8.00;

[0089] 2.3 Heat the water to 85°C, mix cheese, cream, stabilizer, emulsifier, residual acidity regulator, sweetener, etc. with water, stir at high speed until dissolved, and cool to o...

Embodiment 2

[0094] 1. Recipe

[0095] Milk: 800 kg;

[0096] Coffee: 20 kg;

[0097] Glucose: 10 kg;

[0098] Cheese: 3 kg;

[0099] Sweetener: 35 kg;

[0100] Cream: 3 kg;

[0101] Stabilizer: 0.3 kg;

[0102] Emulsifier: 1.2 kg;

[0103] Acidity regulator: 3 kg;

[0104] Water: make up to 1000 kg.

[0105] 2. Preparation method

[0106] 2.1 Milk and glucose were mixed, heated to 93°C, stirred and dissolved for 5 minutes, left to stand for insulation and browning, the browning temperature was 93°C, and the holding time was 2.5 hours, and cooled to obtain a milk base;

[0107] 2.2 Dissolve the coffee with an appropriate amount of water, stir and dissolve for 10-30 minutes and mix evenly, add an appropriate amount of acidity regulator, stir and mix evenly to obtain a coffee base with a pH value of 6.80;

[0108] 2.3 Heat the water to 60°C, mix cheese, cream, stabilizer, emulsifier, residual acidity regulator, sweetener, etc. with water, stir at high speed until dissolved, and coo...

Embodiment 3

[0113] 1. Recipe

[0114] Milk: 400 kg;

[0115] Coffee: 10 kg;

[0116] Glucose: 30 kg;

[0117] Cheese: 5 kg;

[0118] Sweetener: 23 kg;

[0119] Cream: 20 kg;

[0120] Stabilizer: 1.8 kg;

[0121] Emulsifier: 1.8 kg;

[0122] Acidity regulator: 1.3 kg;

[0123] Water: make up to 1000 kg.

[0124] 2. Preparation method

[0125] 2.1 milk is mixed with glucose, heated to 96 ℃, stirred and dissolved for 5 minutes, left to stand for insulation browning, the browning temperature is 96 ℃, the holding time is 2.5 hours, and cooled to obtain a milk base;

[0126] 2.2 Dissolve the coffee with an appropriate amount of water, stir and dissolve for 10-30 minutes and mix evenly, add an appropriate amount of acidity regulator, stir and mix evenly to obtain a coffee base with a pH value of 5.50;

[0127] 2.3 Heat the water to 82°C, mix cheese, cream, stabilizer, emulsifier, residual acidity regulator, sweetener, etc. with water, stir at high speed until dissolved, and cool to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com