Special powder for producing high-quality mochi and making method of powder

A production method and special flour technology are applied to the special flour for mochi and the field of production thereof, which can solve the problems of inability to industrialize production, short shelf life, easy to harden, etc., and achieve the improvement of energy utilization rate, the simplification of production process, and the reduction of cooking. The effect of syrup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

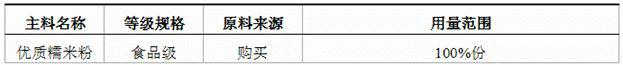

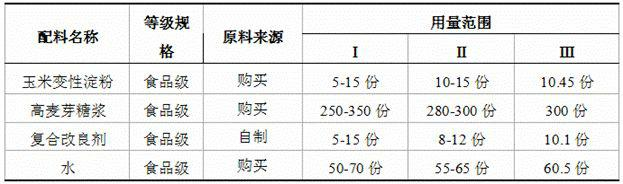

[0034] Formula: glutinous rice flour 100kg, corn modified starch 15kg, high maltose syrup 300kg, compound improver 12kg, water 50kg.

[0035] Make it as follows:

[0036] ⑴ Ingredients: Select high-quality glutinous rice flour, corn modified starch, compound improver and water according to the proportion of the formula, add them to the steamer in turn, stir fully for 15 minutes, and mix well;

[0037] ⑵ Steaming of raw materials: heat and mature the uniformly mixed raw materials under high pressure at 1 kgf / cm 2 Steam for 25 minutes under steam pressure conditions;

[0038] (3) Sugar mixing: change the steam inlet path of the steam refining machine, supply heat in the interlayer, take high maltose syrup, gradually add steamed raw materials in four times, stir for 60 minutes, so that the syrup and powder are fully mixed;

[0039] ⑷ Cooking: Take out the cooked powder mixed with syrup from the steamer;

[0040] ⑸ Cooling: Seal the cooked powder with plastic wrap, and place it...

Embodiment 2

[0049] Formula: glutinous rice flour 100kg, corn modified starch 10.45kg, high maltose syrup 250kg, compound improver 6kg, water 70kg.

[0050] Make it as follows:

[0051] ⑴ Ingredients: Select high-quality glutinous rice flour, corn modified starch, compound improver and water according to the formula ratio, add them to the steamer in turn, stir fully for 20 minutes, and mix well;

[0052] ⑵ Steaming of raw materials: heat and mature the uniformly mixed raw materials under high pressure at 1.2 kgf / cm 2 Steam under steam pressure conditions for 20min;

[0053] (3) Sugar mixing: change the steam inlet path of the steamer, supply heat in the interlayer, take high maltose syrup, add the steamed raw materials gradually in four times, stir for 50 minutes, so that the syrup and powder are fully mixed;

[0054] ⑷ Cooking: Take out the cooked powder mixed with syrup from the steamer;

[0055] ⑸ Cooling: Seal the cooked powder with plastic wrap, and place it at room temperature for...

Embodiment 3

[0064] Formula: glutinous rice flour 100kg, corn modified starch 13.5kg, high maltose syrup 280kg, compound improver 8kg, water 60kg.

[0065] Make it as follows:

[0066] ⑴ Ingredients: Select high-quality glutinous rice flour, corn modified starch, compound improver and water according to the proportion of the formula, add them to the steamer in turn, stir fully for 25 minutes, and mix well;

[0067]⑵ Steaming of raw materials: heat and mature the uniformly mixed raw materials under high pressure at 0.5 kgf / cm 2 Steam under steam pressure conditions for 22 minutes;

[0068] (3) Sugar mixing: change the steam inlet path of the steam refining machine, supply heat in the interlayer, take high maltose syrup, gradually add steamed raw materials in four times, stir for 55 minutes, so that the syrup and powder are fully mixed;

[0069] ⑷ Cooking: Take out the cooked powder mixed with syrup from the steamer;

[0070] ⑸ Cooling: Seal the cooked powder with plastic wrap and place i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com