Frozen beverage and making method thereof

A frozen drink and protein powder technology, which is applied in the food field, can solve problems such as difficulty in meeting the dietary needs of special groups of people, and achieve the effect of unique flavor and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

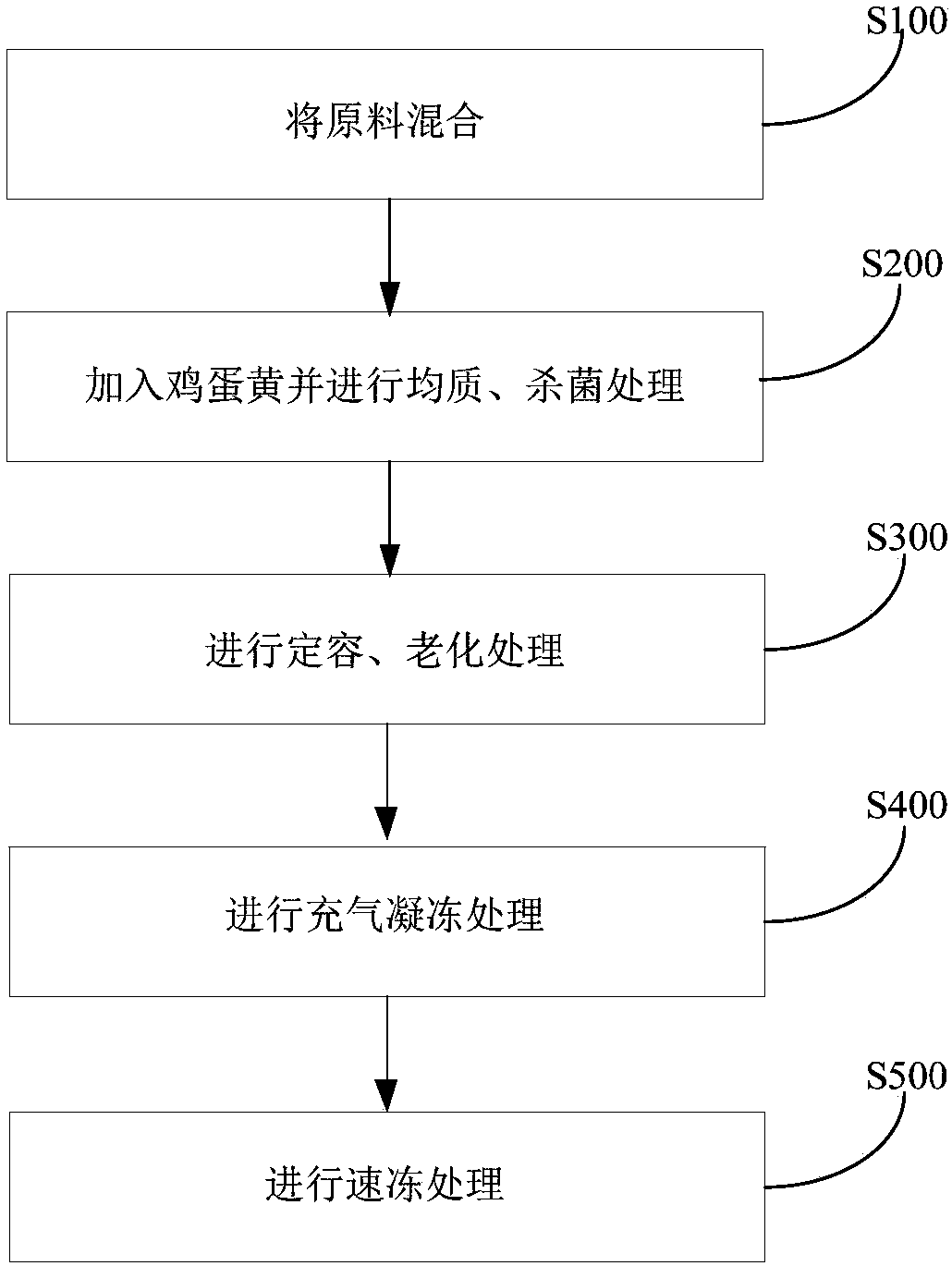

Method used

Image

Examples

Embodiment 1

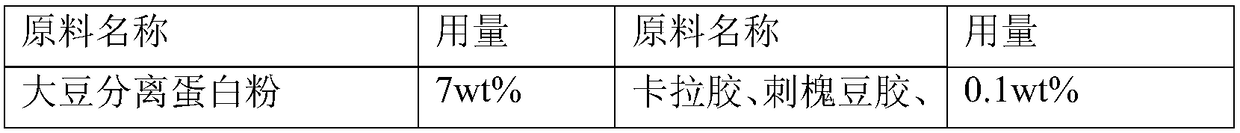

[0076] Prepare frozen drinks as described in the following recipes and general methods:

[0077] Table 1 Frozen Drink Recipe 1

[0078]

[0079]

Embodiment 2

[0081] According to the formula of embodiment 1 and following method prepare frozen drink:

[0082](1) Mix and stir soybean protein isolate powder, calcium caseinate and compound stabilizer evenly, then add drinking water at 50 degrees Celsius; (2) add oil to the mixture obtained in step (1), and stir at 65 degrees Celsius 30 minutes, so that obtain the first mixture; (3) add egg yolk in the first mixture, carry out homogenization treatment under pressure 180bar, temperature 75 degrees Celsius after stirring, then sterilize at 95 degrees Celsius for 3 minutes, so that obtain The second mixture; (4) the second mixture is cooled to 3.5 degrees Celsius, and aged at 4 degrees Celsius after constant volume for 10 hours, so as to obtain the aged material; The expansion ratio is 50%; (6) the mixture obtained in step (5) is subjected to quick-freezing treatment at -34 degrees Celsius, so as to obtain a frozen drink.

Embodiment 3

[0084] According to the formula of embodiment 1 and following method prepare frozen drink:

[0085] (1) Mix and stir soybean protein isolate powder, calcium caseinate and compound stabilizer evenly, then add drinking water at 30 degrees Celsius; (2) add oil to the mixture obtained in step (1), and stir at 60 degrees Celsius 30 minutes, so that obtain the first mixture; (3) add egg yolk in the first mixture, carry out homogenization treatment under pressure 180bar, temperature 70 degrees Celsius after stirring, then sterilize at 95 degrees Celsius for 3 minutes, in order to obtain The second mixture; (4) the second mixture is cooled to 3.5 degrees Celsius, and aged at 4 degrees Celsius after constant volume for 10 hours, so as to obtain the aged material; The expansion ratio is 10%; (6) the mixture obtained in step (5) is subjected to quick-freezing treatment at -34 degrees Celsius, so as to obtain a frozen drink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com