Heating non-combustion cigarette filter and heating non-combustion cigarette

A heat-not-burn, cigarette filter technology is applied in the fields of heat-not-burn cigarette filters and heat-not-burn cigarettes. effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

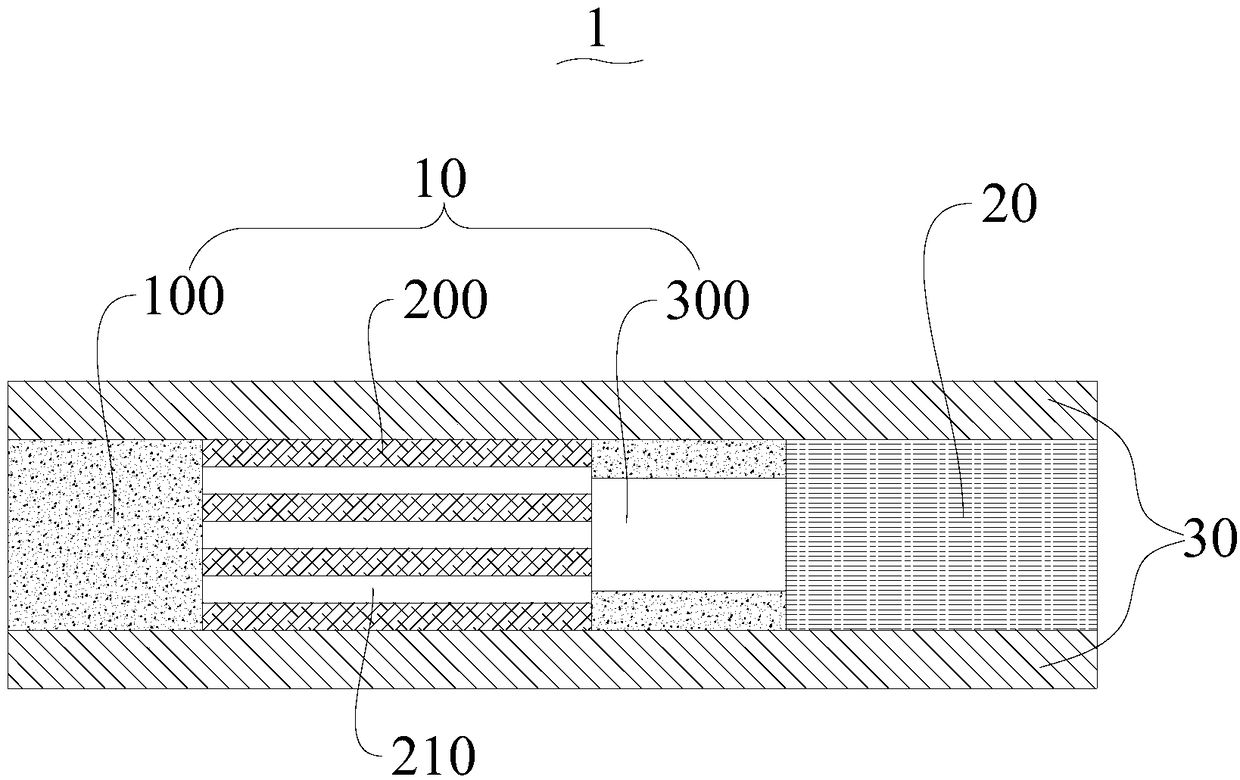

[0063] Such as figure 1 As shown, a heat-not-burn cigarette 1 includes a heat-not-burn cigarette filter 10 and a tobacco rod 20 . The heat-not-burn cigarette filter 10 includes a cellulose acetate filter rod 100 , a cooling part 200 and a hollow part 300 connected in sequence. The cooling part 200 includes a plurality of through-cavity passages 210, and the middle part of the hollow part 300 is a through-cavity structure. The wall thickness of the hollow portion 300 is slightly greater than the outer wall thickness of the cooling portion 200 . The cooling part 200 is made of polylactic acid, and the hollow part 300 is made of cellulose acetate.

[0064] The tobacco rod 20 is connected with the hollow part 300, and the heat-not-burn cigarette filter and the tobacco rod 20 are wrapped with forming paper to form a whole cigarette.

[0065] When the above-mentioned heat-not-burn cigarette 1 is used for smoking, the tobacco end is inserted into a corresponding heating device for...

Embodiment 2

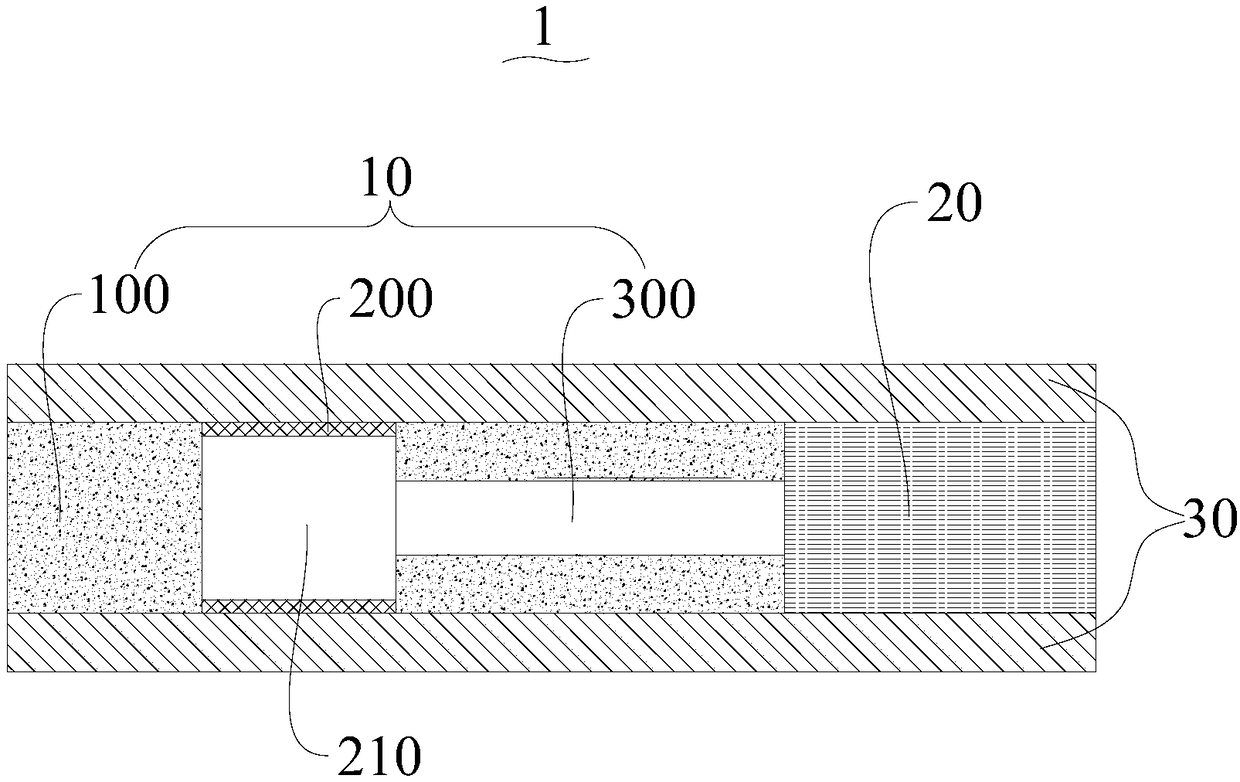

[0067] Such as figure 2 As shown, a heat-not-burn cigarette 1 includes a heat-not-burn cigarette filter 10 and a tobacco rod 20 . The heat-not-burn cigarette filter 10 includes a cellulose acetate filter rod 100 , a cooling part 200 and a hollow part 300 connected in sequence. The cooling part 200 includes a through cavity channel 210, and the middle part of the hollow part 300 is a through cavity structure. The wall thickness of the hollow portion 300 is slightly greater than the wall thickness of the cooling portion 200 . The cooling part 200 is made of paper, and the hollow part 300 is made of cellulose acetate.

[0068] The tobacco rod 20 is connected with the hollow part 300, and the heat-not-burn cigarette filter and the tobacco rod 20 are wrapped with forming paper to form a whole cigarette.

[0069] When the above-mentioned heat-not-burn cigarette 1 is used for smoking, the tobacco end is inserted into the corresponding heating device for heating. After the heating...

Embodiment 3

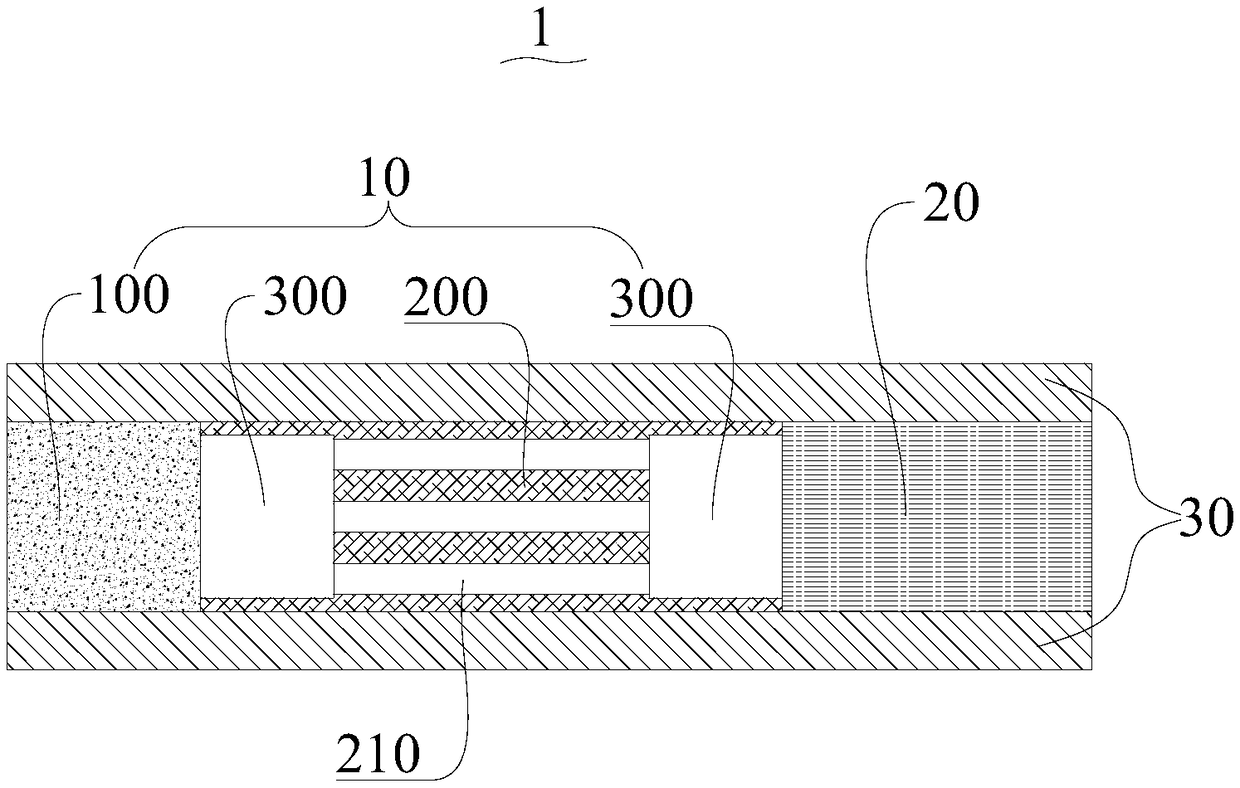

[0071] Such as image 3 As shown, a heat-not-burn cigarette 1 includes a heat-not-burn cigarette filter 10 and a tobacco rod 20 . The heat-not-burn cigarette filter 10 includes a cellulose acetate filter rod 100 and an integrally formed cooling part 200 and a hollow part 300. The cooling part 200 includes a plurality of hollow passages 210 through which the middle part of the hollow part 300 It is a through cavity structure. The cooling part 200 is located in the middle of the hollow part 300 .

[0072] The cellulose acetate filter rod 100 is connected to the first end of the hollow part 300, the tobacco rod 20 is connected to the second end of the hollow part 300, and the heat-not-burn cigarette filter 10 and the tobacco rod 20 Wrapped into a whole cigarette by forming paper.

[0073] When the above-mentioned heat-not-burn cigarette 1 is used for smoking, the tobacco end is inserted into the corresponding heating device for heating. After the heating is completed, smoke is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com