Extruding universal formwork

A common mold base and mold base technology, applied in the field of extrusion, can solve the problems of affecting production efficiency, cumbersome mold base replacement process, and low versatility of mold bases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

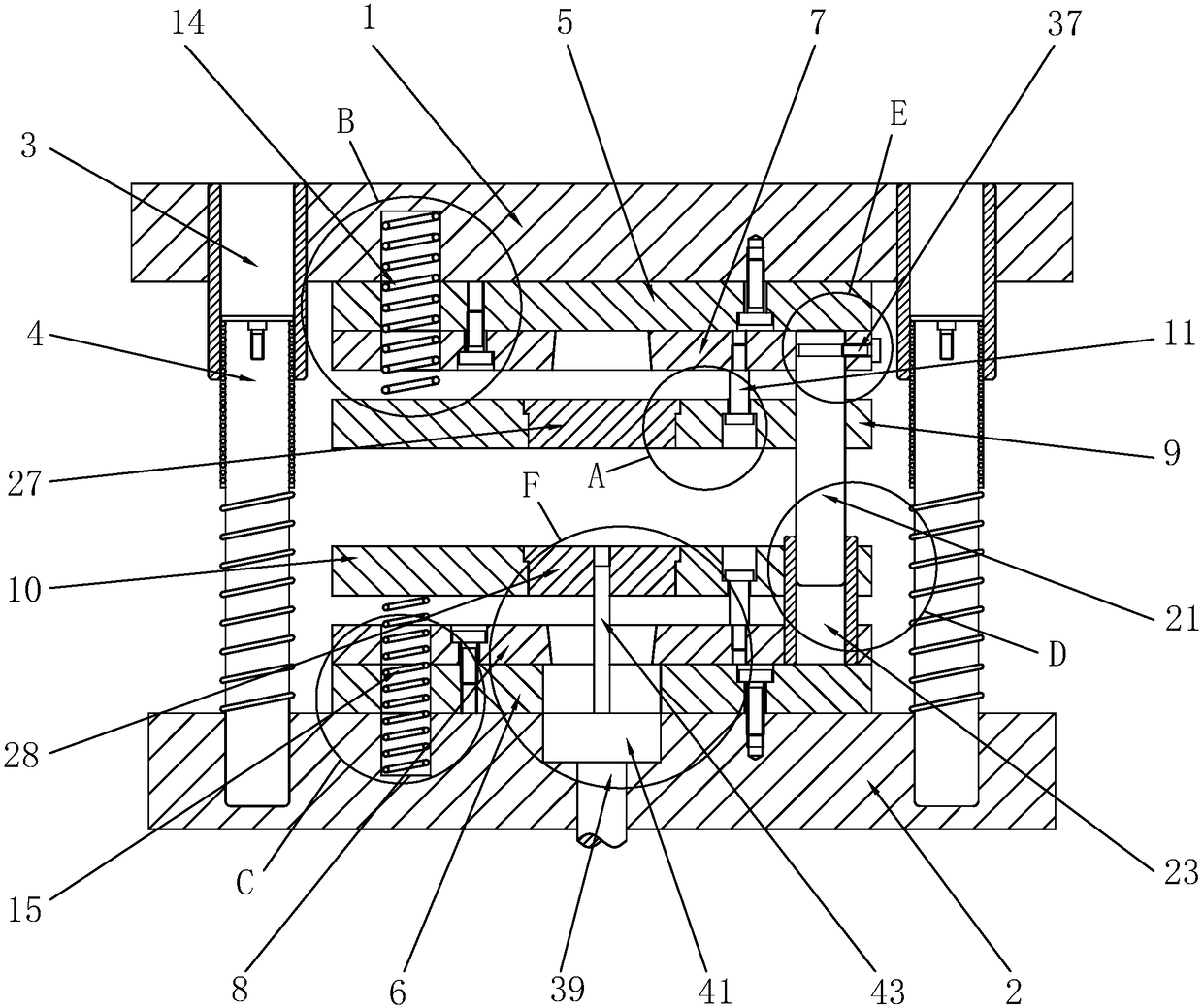

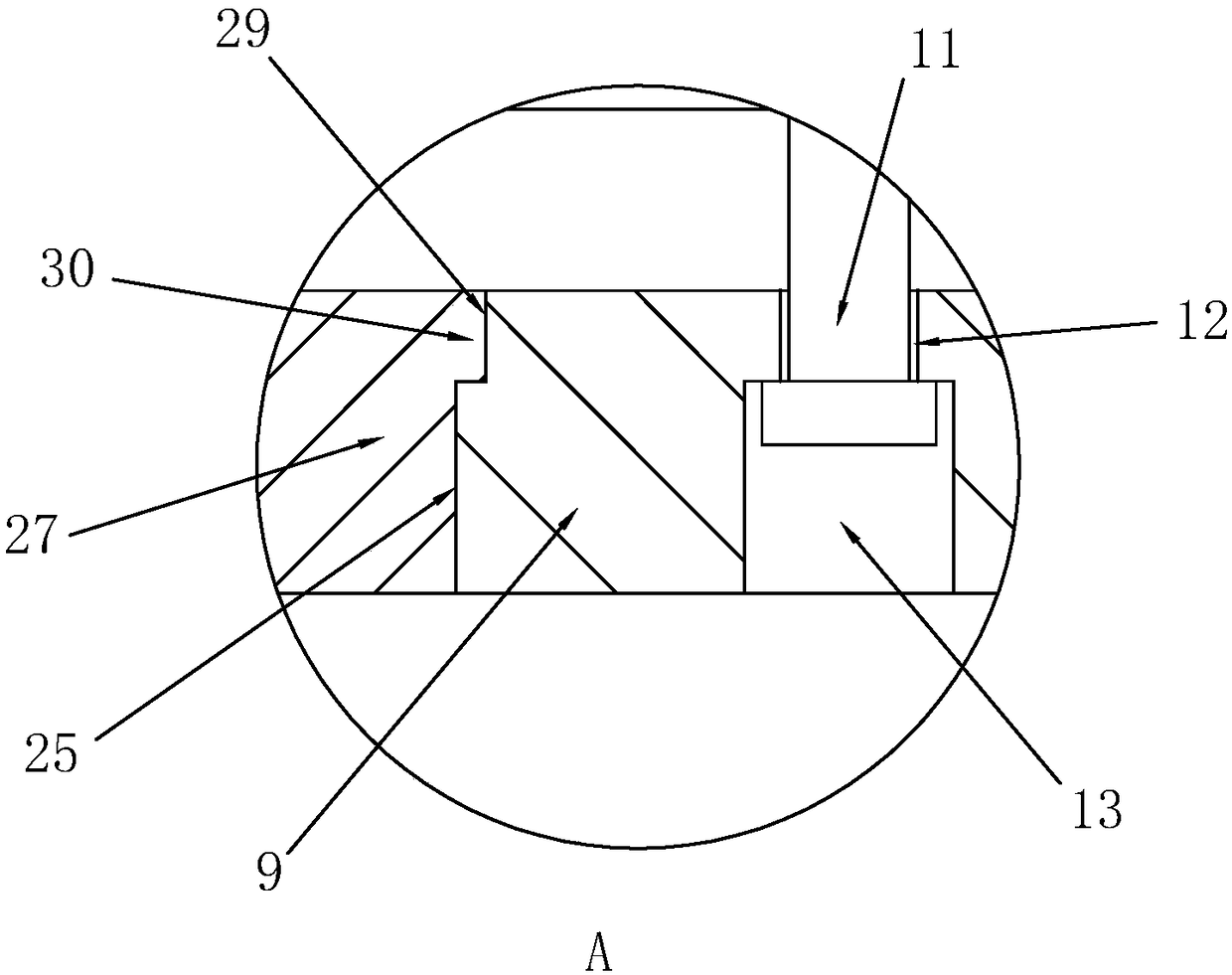

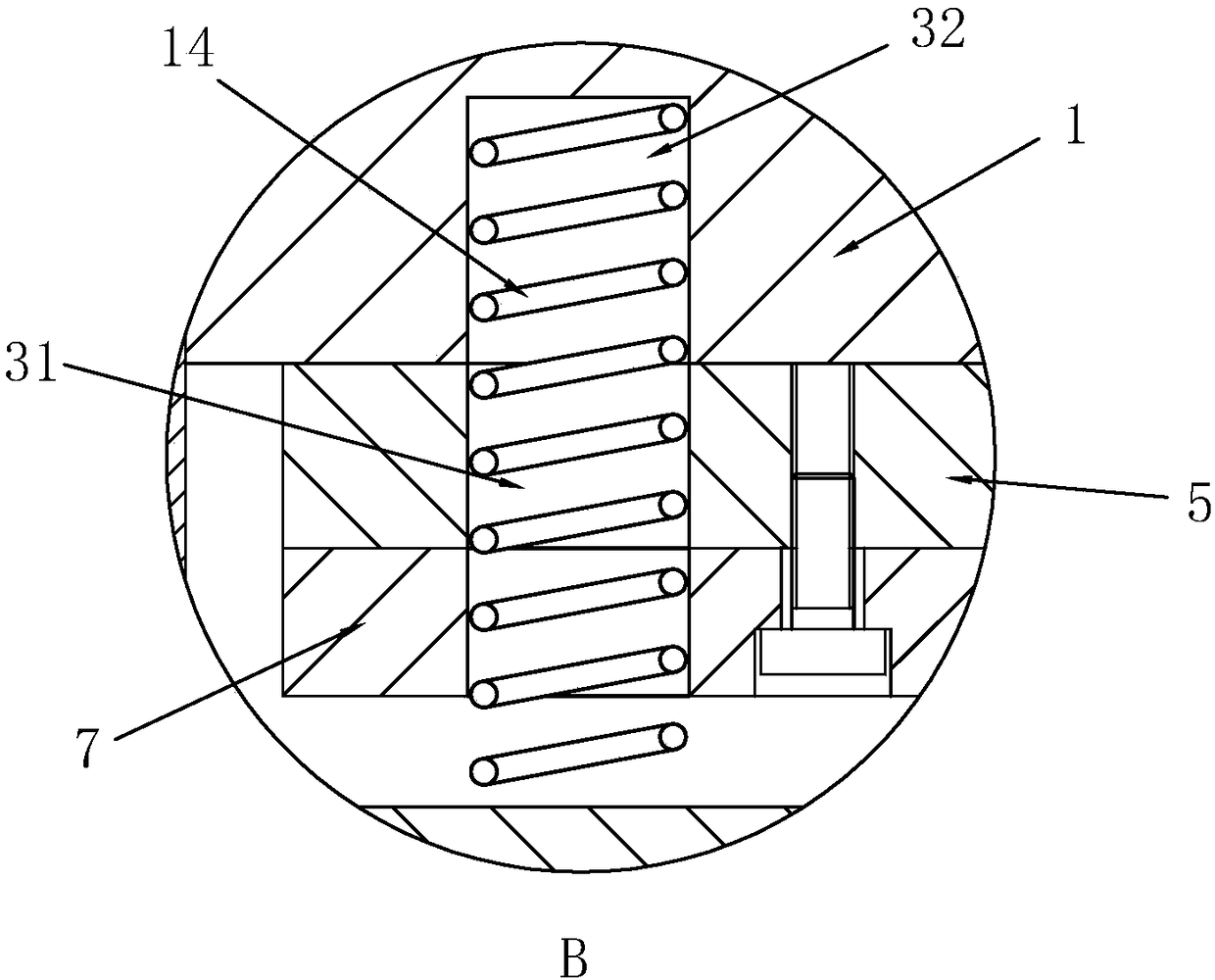

[0043] Embodiment 1: A kind of extruded universal formwork, such as figure 1 As shown, it includes an upper mold base 1 and a lower mold base 2; a guide sleeve 3 is plugged into the upper mold base 1 in the form of an interference fit, and a sliding end is inserted into the lower mold base 2 in the form of an interference fit The guide post 4 inserted into the guide sleeve 3; among them, the guide post 4 is preferably a ball guide post, which has the characteristics of high precision and long service life, and is suitable for precision molds with high precision and long life and punching of thin materials mold. Upper die base 1 is connected with upper backing plate 5 by screws, lower die base 2 is connected with lower backing plate 6 by screws; upper backing plate 5 is connected with upper stress backing plate 7 by screws, and lower backing plate 6 is connected with lower stress by screws Backing plate 8.

[0044] combine image 3 and Figure 4 , the extruded universal for...

Embodiment 2

[0050] Embodiment 2: as Figure 9 and Figure 10 As shown, the difference from Embodiment 1 is that the upper stripping plate 9, the lower stripping plate 10, the upper template 16 and the lower template 17 are provided with pin holes 20 for installing positioning pins 19. After the spring is unloaded, the upper backing plate 5, the upper stress backing plate 7 and the upper stripping plate 9 are rigidly connected by screws, and the upper template 16 is mounted on the upper stripping plate 9; the lower template 17 is installed on the lower stripping plate 10 superior. The second spring acts as a buffer when closing the mold to prevent the extruded part from being torn due to excessive impact.

Embodiment 3

[0051] Example 3: Binding Figure 10 and Figure 11 , the difference from Example 1 is that pin holes 20 are provided on the upper stripping plate 9, the lower stripping plate 10, the upper template 16 and the lower template 17, and the pin holes 20 are inserted with positioning pins 19 in the form of transition fit. . After the spring 2 is removed, the lower backing plate 6, the lower stress backing plate 8 and the lower stripping plate 10 are rigidly connected by screws, and the upper template 16 is mounted on the upper stripping plate 9; the lower template 17 is installed on the lower stripping plate 10 superior. When the spring is closed, it acts as a buffer to prevent the extruded part from being torn due to excessive impact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com