Robot work state intelligent judgment system under high-temperature environment

A technology of working status and intelligent judgment, applied to manipulators, manufacturing tools, etc., can solve problems such as safety accidents, equipment damage, robot instability, etc., and achieve the effect of timely response, fewer components, and avoiding major failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

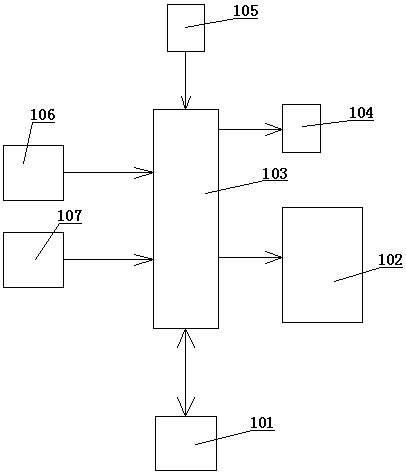

[0015] The intelligent judging system of the working state of the robot under the high temperature environment of the present invention comprises a robot information receiving and feedback module 101, a digital screen display module 102, a PLC processing system module 103, an automatic alarm module 104, a manual data input module 105, a video data acquisition module 106 and The temperature data acquisition module 107 is characterized in that: the robot information receiving feedback module 101 is bidirectionally connected with the PLC processing system module 103, and the signal output end of the manual data input module 105 is connected with the input end of the PLC processing system module 103; The output terminal of the PLC processing system module 103 is connected with the digital screen display module 102 .

[0016] As a preferred solution of the present invention, the output end of the PLC processing system module 103 is connected to the automatic alarm module 104 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com