Walking type conveyor cooperating with coal mining machine

A walking and conveyor technology is applied in the field of walking conveyors and coal mining operations in open-pit coal mines, which can solve problems such as affecting the normal transportation of coal flow, deviation of belt conveyors, and insufficient length of belt conveyors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in conjunction with the accompanying drawings.

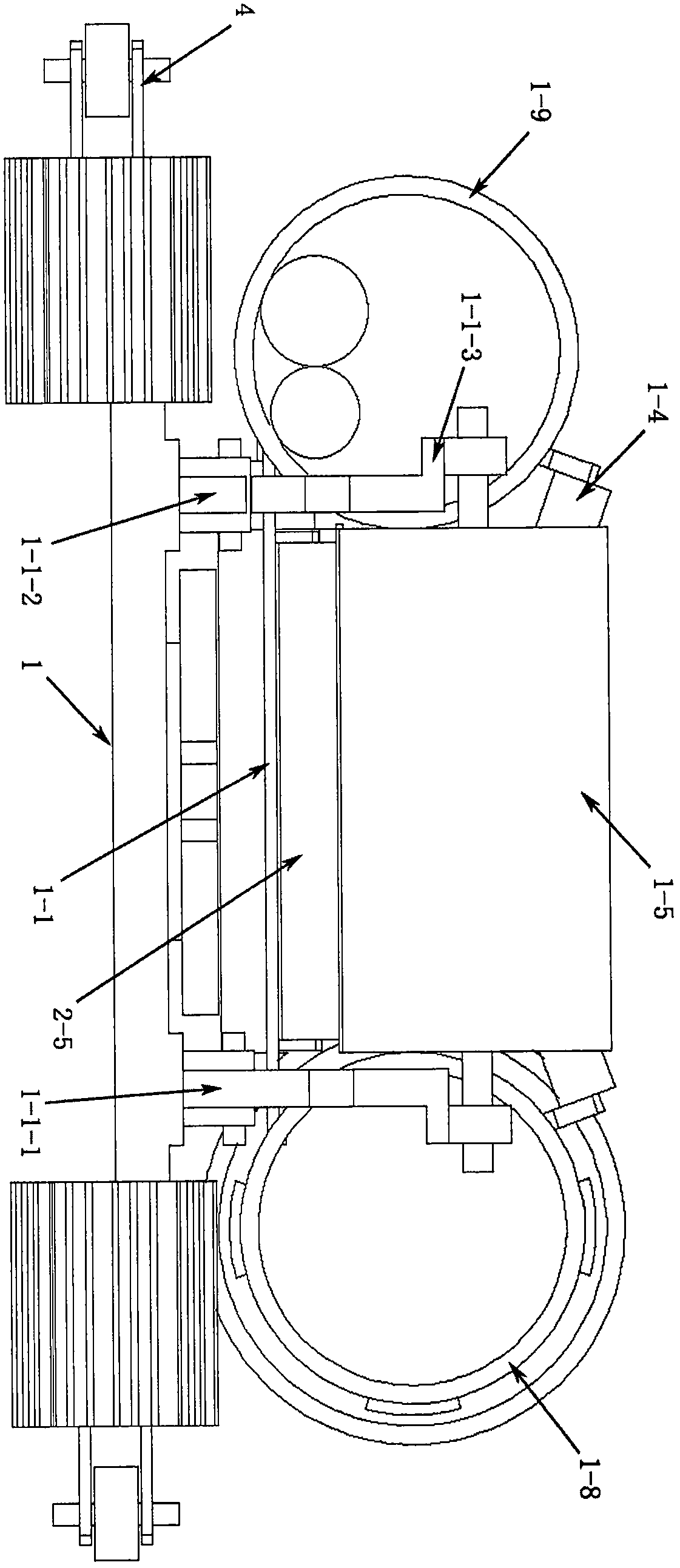

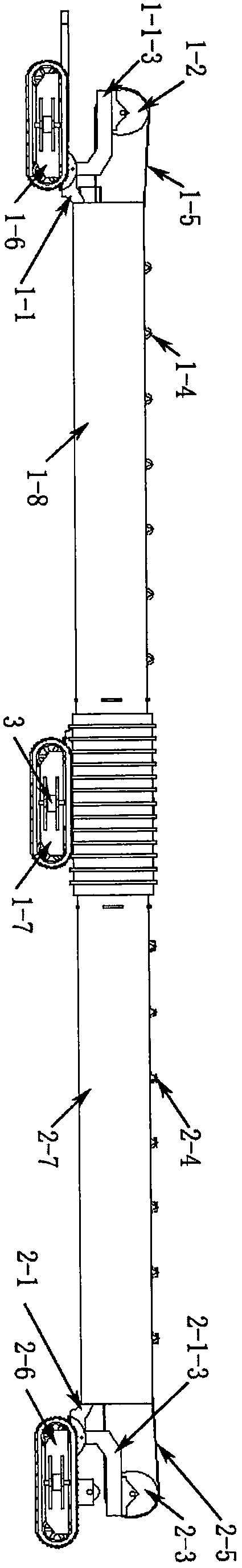

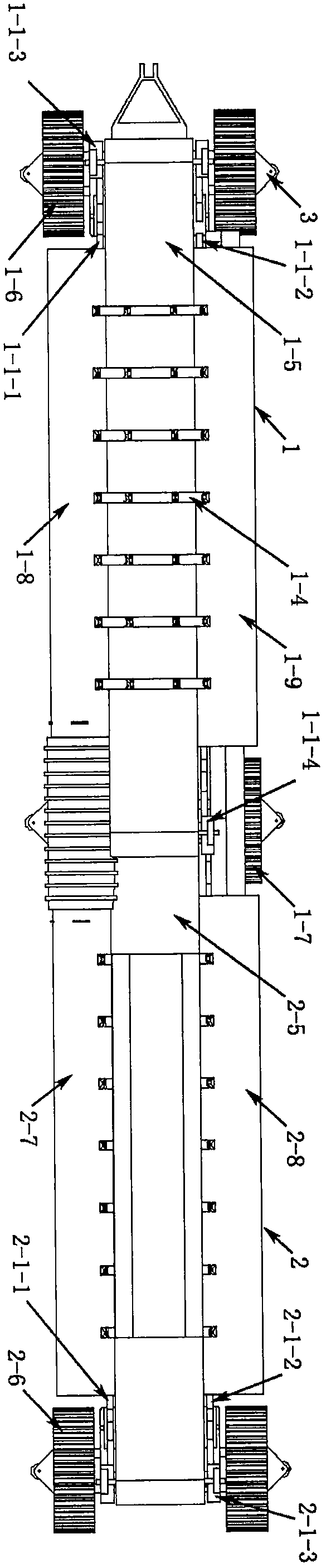

[0044] like figure 1 , 2 , 3, shown in 4, structure of the present invention is as follows:

[0045] A walking conveyor used in conjunction with a coal mining machine, the walking conveyor is connected to the position of the coal outlet at the rear end of the continuous coal mining machine, and the walking conveyor includes at least two walking conveyors Machine: the first walking conveyor 1 and the second walking conveyor 2, the first walking conveyor 1 includes: the first support 1-1, the first driving roller 1-2, the first diverting roller 1-3 , the first trough roller 1-4, the first conveyor belt 1-5, the first traveling device 1-6, the second traveling device 1-7, the first left and right steel pipes 1-8, 1-9, wherein :

[0046] The first bracket 1-1 includes first left and right beams 1-1-1, 1-1-2, and the front and rear upper parts of the first left and right beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com