Electric control valve

An electric control valve and valve body technology, which is applied to the valve details, valve device, valve shell structure, etc., can solve the problems that the welding parts are easy to be corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

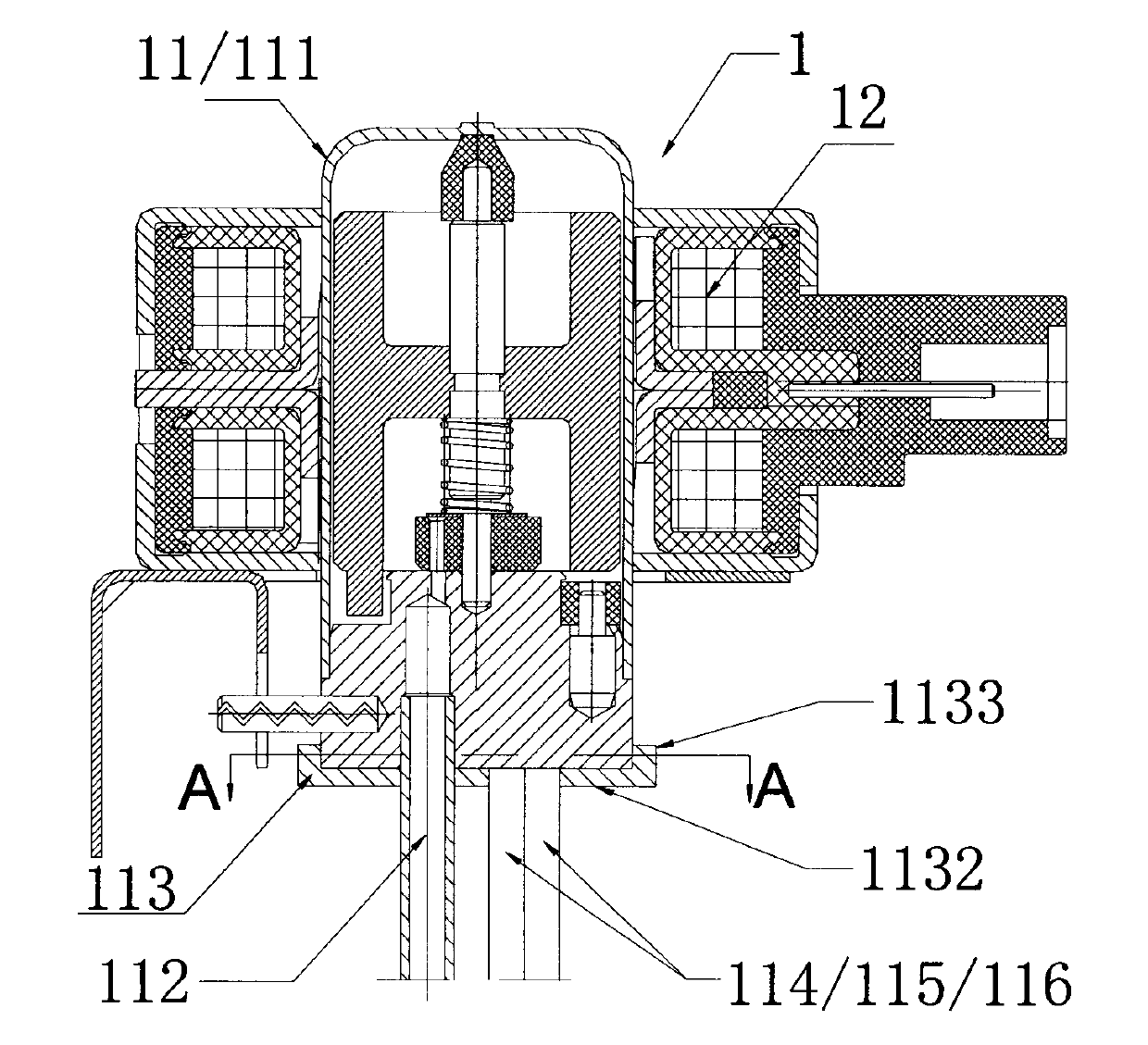

[0027] Please refer to figure 1 , figure 2 , figure 1 is a schematic diagram of the electric control valve according to the first embodiment of the present invention, figure 2 Yes figure 1 A-A cross-sectional view. The electric control valve 1 includes a valve body part 11 and a coil part 12, and the valve body part 11 is composed of a valve body 111 and a connecting pipe. In this embodiment, the electric control valve 1 is used to switch the refrigerant flow path, and has one inlet and three outlets, wherein the inlet is welded and fixed with an inlet connecting pipe 112, and the three outlets are respectively welded with outlet connecting pipes 114 / 115 / 116.

[0028] The relative positions of the valve body part 11 and the coil part 12 can be fixed by a fixing method generally adopted in the prior art, which is not limited in this embodiment.

[0029] In this embodiment, the electric control valve 1 also includes a protection device. Specifically, the protection devi...

no. 2 approach

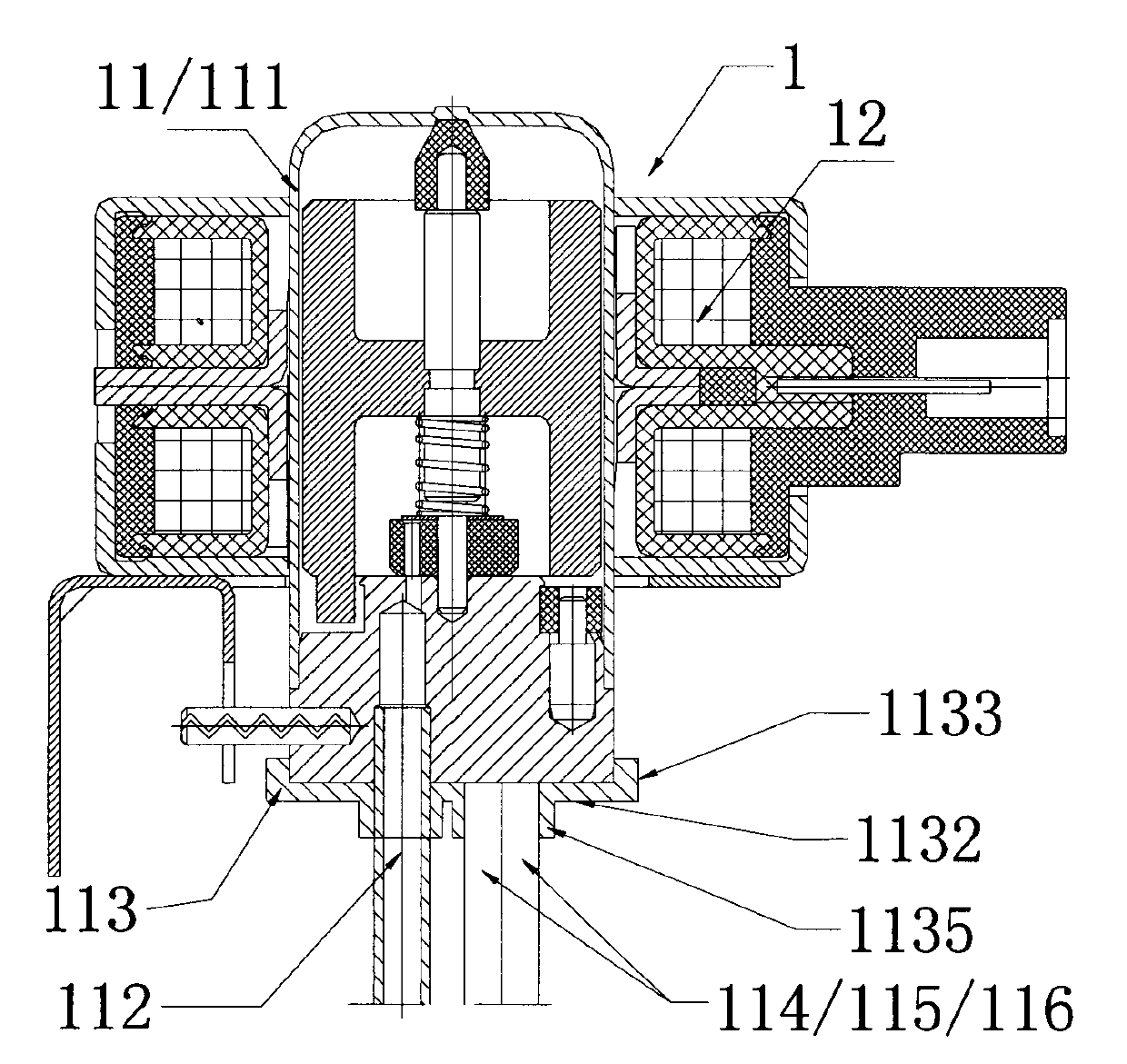

[0036] Attached below image 3 , to describe the second embodiment of the present invention.

[0037] The second embodiment is an improvement made on the first embodiment. The electric control valve with three outlets is still used as an example for illustration. Based on the enlightenment of the present invention, those skilled in the art can also apply this embodiment to different outlets. Among the number of electric control valves. In addition, the same parts as those in the above-mentioned first embodiment will not be repeated, and only the differences will be described.

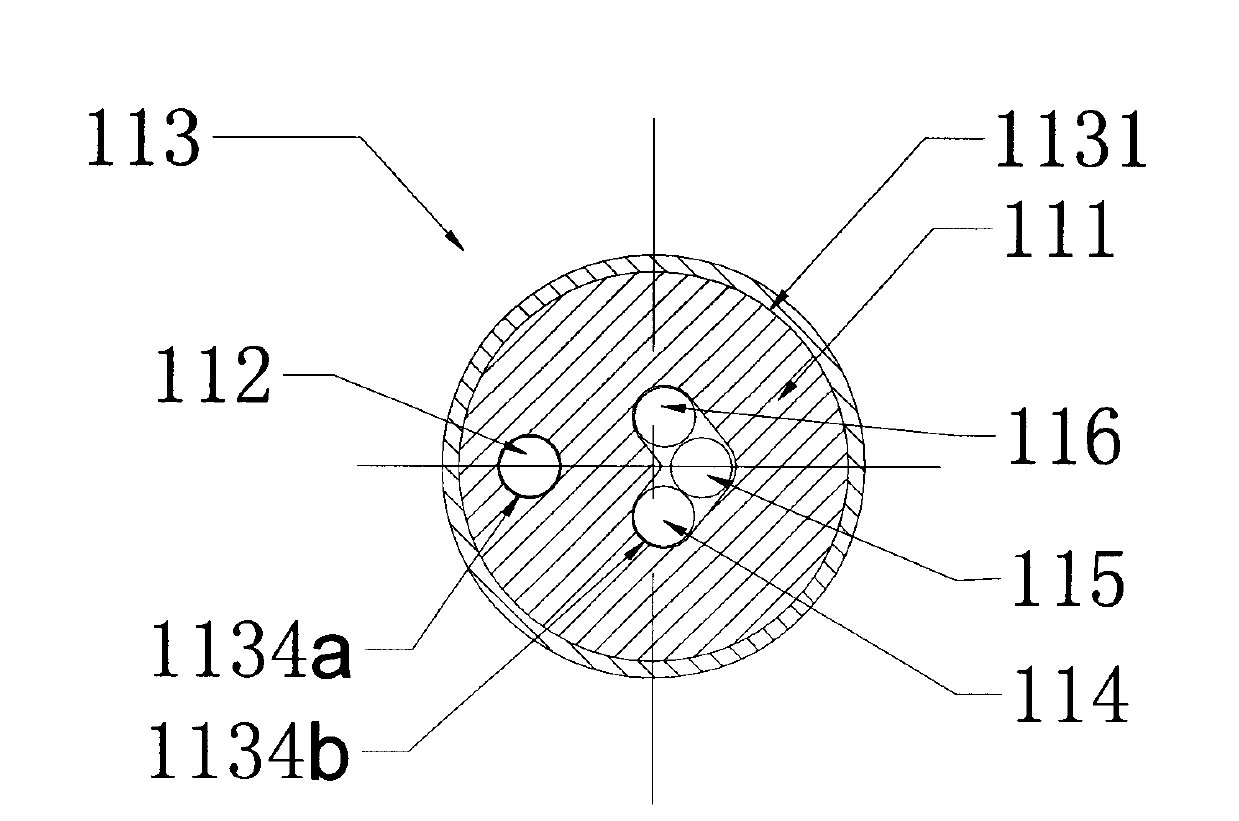

[0038] Please refer to image 3 . image 3 It is a schematic diagram of the electric control valve according to the second embodiment of the present invention.

[0039] The protective cover 113 is generally in a cylindrical shape, surrounded by a peripheral wall 1133 to form an accommodating cavity 1131 , and has a bottom 1132 . A channel portion 1134 is opened on the bottom plane, and the shape of...

no. 3 approach

[0045] Combine below Figure 4 , Figure 5 , the third embodiment of the present invention will be described.

[0046] The third embodiment is a further optimization of the second embodiment. like Figure 4 , Figure 5 as shown, Figure 4 It is a schematic diagram of the electric control valve according to the third embodiment of the present invention, Figure 5 It is a structural schematic diagram of the protective cover of the third embodiment.

[0047] Of course, the same optimization can also be performed on the basis of the first embodiment to obtain a new technical solution.

[0048] The difference from the second embodiment is that the protective sleeve 113 is also provided with a first connecting portion, the first connecting portion is arranged on the other end surface opposite to the bottom surface 1132 of the protective sleeve 113 and protrudes from the end of the protective sleeve 113 in the radial direction. side edge. The first connecting part is specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com