Ceramic vessel clay blank rolling former with protection function

A roll forming machine and ceramic container technology, applied in the direction of ceramic forming machine, forming pressure head, auxiliary forming equipment, etc., can solve the problems affecting product quality, shortening service life, affecting the overall structure of the machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

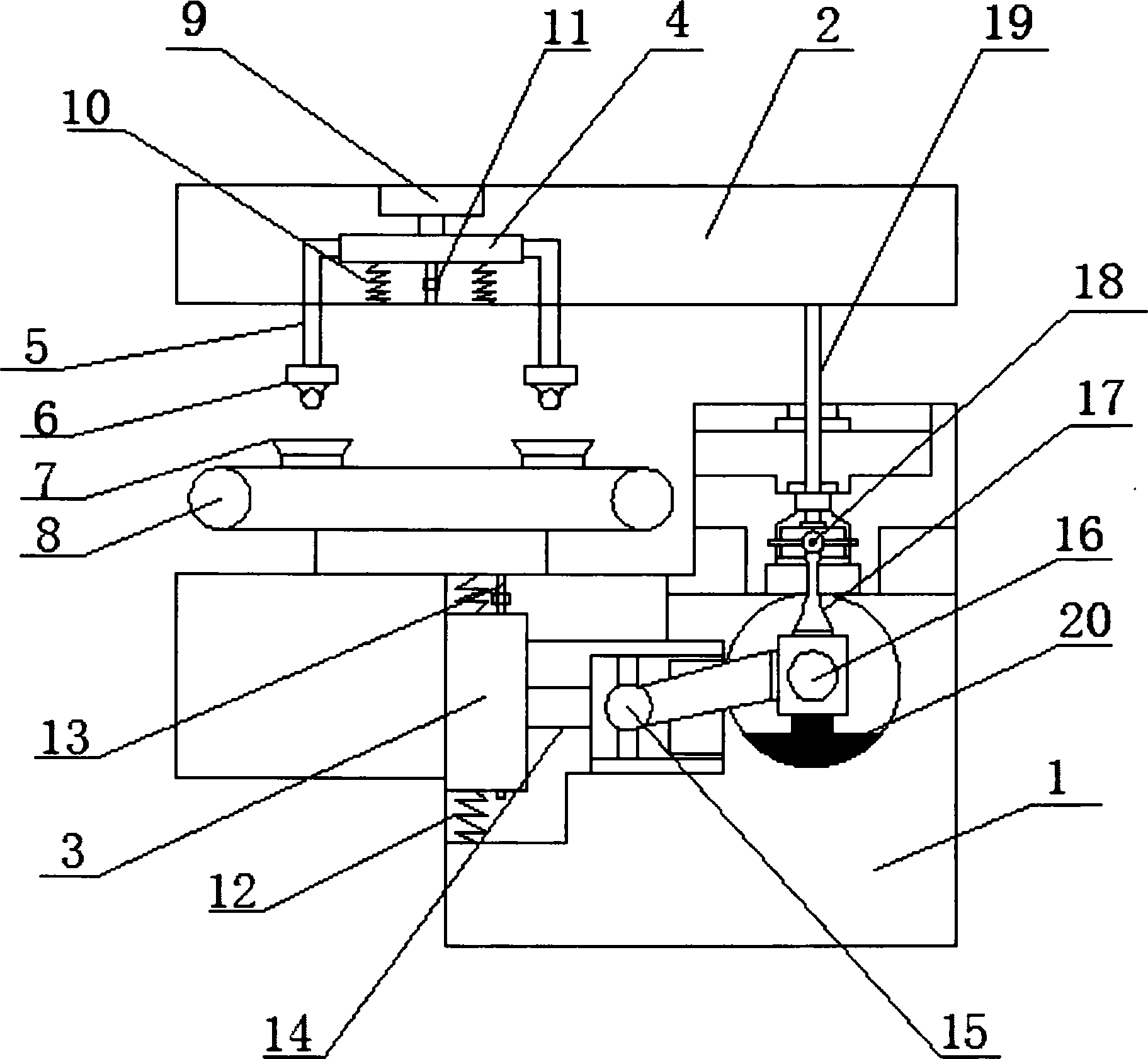

[0017] like figure 1 A ceramic container mud rolling forming machine with protection function is shown, its structure includes a body 1, a mud mold 7 and a forming roller 6, the body 1 is provided with a first motor 3, the first motor 3 The first coil spring 12 and the first damper 13 are connected to the fuselage 1; the first motor 3 is connected to the lifting platform 2 located above the fuselage 1 through a transmission lifting device, and the second motor 4 is arranged in the lifting platform 2, and the second motor 4 is arranged in the lifting platform 2. The second motor 4 is connected with the forming roller 6 through the roller shaft 5; the second motor 4 is connected with the lifting platform 2 through the second coil spring 10 and the second damper 11; the first damper 13 and the second damper 11 are all energy dissipation dampers. This structure is driven by the first motor 3 to drive the transmission lifting device, so that the lifting platform connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com