Opening operation sleeve angle deflection coordination assembly for pipe shed drilling rig

An angle and drilling rig technology, applied in directional drilling and other directions, can solve problems such as angle deviation, affecting operation effect, and damage to fuselage components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

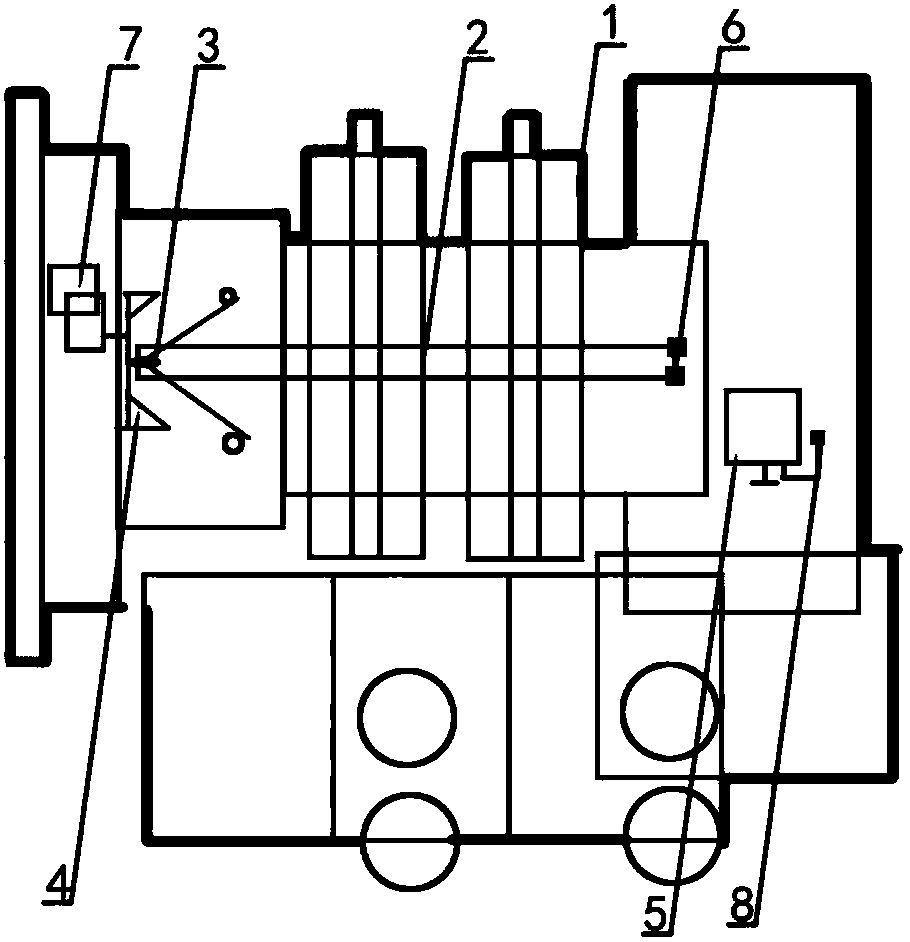

[0012] Embodiment: as shown in the accompanying drawing. The casing angle deflection coordination assembly for the drilling operation of the pipe shed drilling rig includes a body (1), on which a horizontal reference module (2), a triangular fixed point module (3), an angle sensing module (4), a management Module (5), during operation, the horizontal reference module (2) is set near the opening part of the fuselage, the triangle fixed point module (3) is fixed on the casing, and the angle sensing module (4) senses the angle formed by each point and the reference line situation, the management module (5) processes the integrated information.

[0013] An information sensing module (6) is provided on the horizontal reference module (2) of the casing angle deflection coordination component for the drilling operation of the pipe shed drilling rig to transmit the angles formed by each point and the reference line in real time.

[0014] The casing angle deflection coordinating assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com