Angle cutter grinding modular fixture of gear shaper cutter

A technology of combining fixtures and angles, applied in the direction of grinding workpiece supports, etc., can solve the problems of reduced cutting ability, rough rake face, complicated angle adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

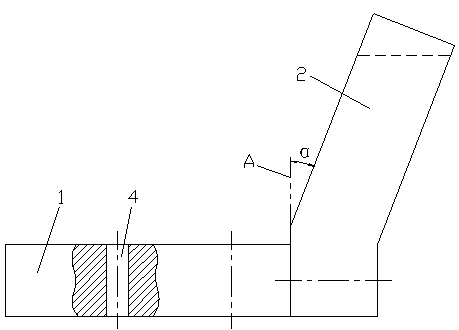

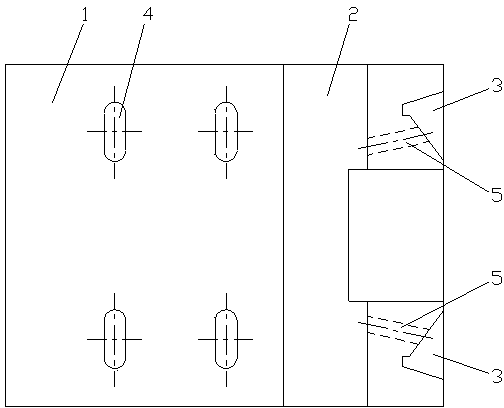

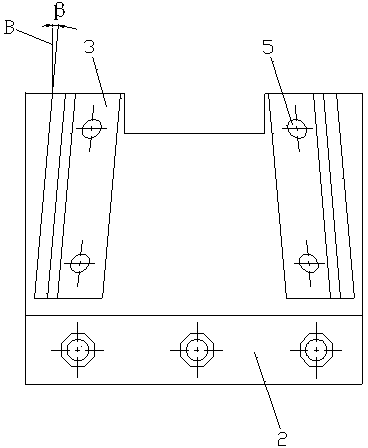

[0017] refer to Figure 1~3 , a combination jig for gear planer angle sharpening, including a base 1 for fixing on a tool grinder, the base 1 is connected with a tool mounting seat 2, and the tool mounting seat 2 is provided with at least one tool for installing a tool The tool clamping groove 3, the tool mounting seat 2 is provided with a rake angle α that intersects the first vertical reference plane A, and the tool clamping groove 3 is provided with a rake angle α that intersects the second vertical reference plane B Blade inclination angle β, the first vertical reference plane A is perpendicular to the second vertical reference plane B.

[0018] In this embodiment, two tool clamping slots 3 for installing tools are provided symmetrically on the tool mounting seat 2 with respect to its longitudinal symmetry plane, and are respectively used for shar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com