Cutting tool for machining fin of automobile radiator

A technology for automotive radiators and cutting tools, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of not being able to meet customer needs, and achieve the effects of reasonable changes, cost saving, and air resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

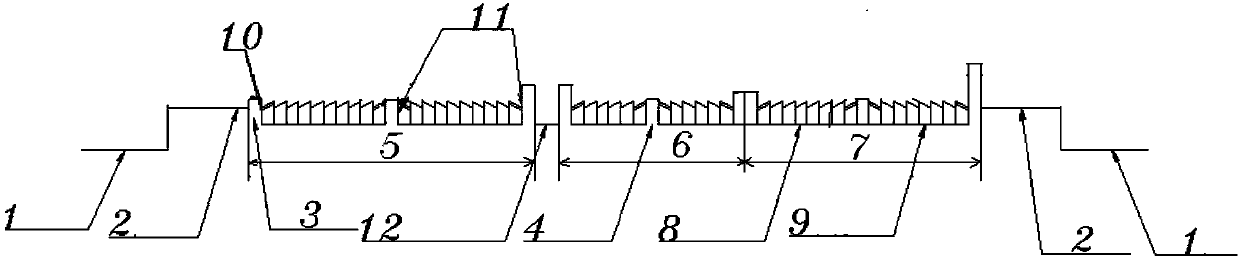

[0018] A cutting tool for processing automobile radiator fins, its structure is as follows figure 1 As shown, the cutter includes a cutter shaft 1, a slab 2 arranged in the axial direction of the cutter shaft 1, and three blade units, each blade unit includes a left-handed knife 8, a right-handed knife 9, and is arranged on the left-handed knife 8 and The flap 4 between the right-handed knives 9 and the spacer 3 arranged at the other end of the left-handed knife 8 and the right-handed knife 9, and the junction of the left-handed knife 8 and the spacer 3 is provided with a left half-edged knife 10, and the right-handed knife 9 A right half-edged knife 11 is provided at the joints of the intermediate sheet 3 and the folding sheet 4.

[0019] The left-handed knife 8 and the right-handed knife 9 both include a plurality of neatly arranged saw-shaped teeth, and the saw-shaped teeth of the left-handed knife 8 and the right-handed knife 9 have opposite cutting edges, and the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com