Bored pile bore hole inspection equipment and bored pile bore hole inspection method

A technology of bored piles and sounding holes, which is applied in the fields of bored pile sounding and bored pile sounding equipment, which can solve problems such as reduced construction efficiency, damage to the construction environment, and poor verticality of pile foundations, so as to improve work efficiency , reduce construction costs and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

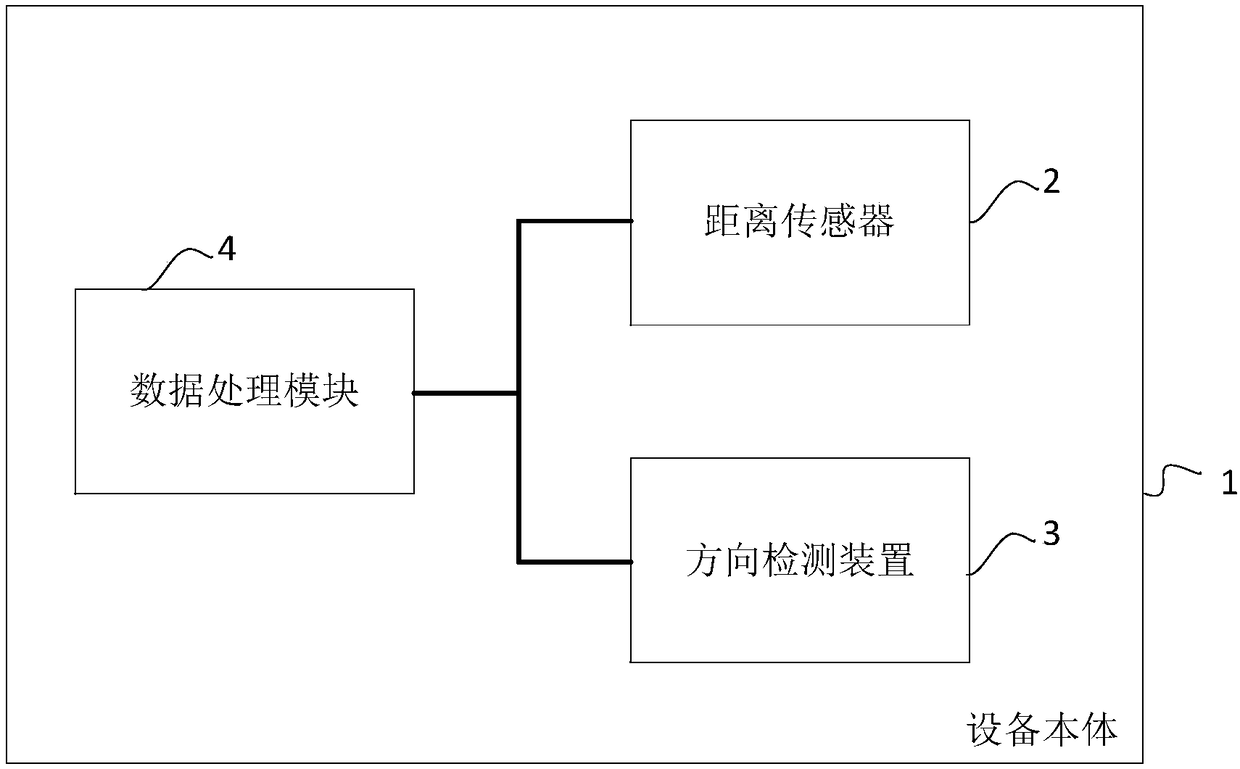

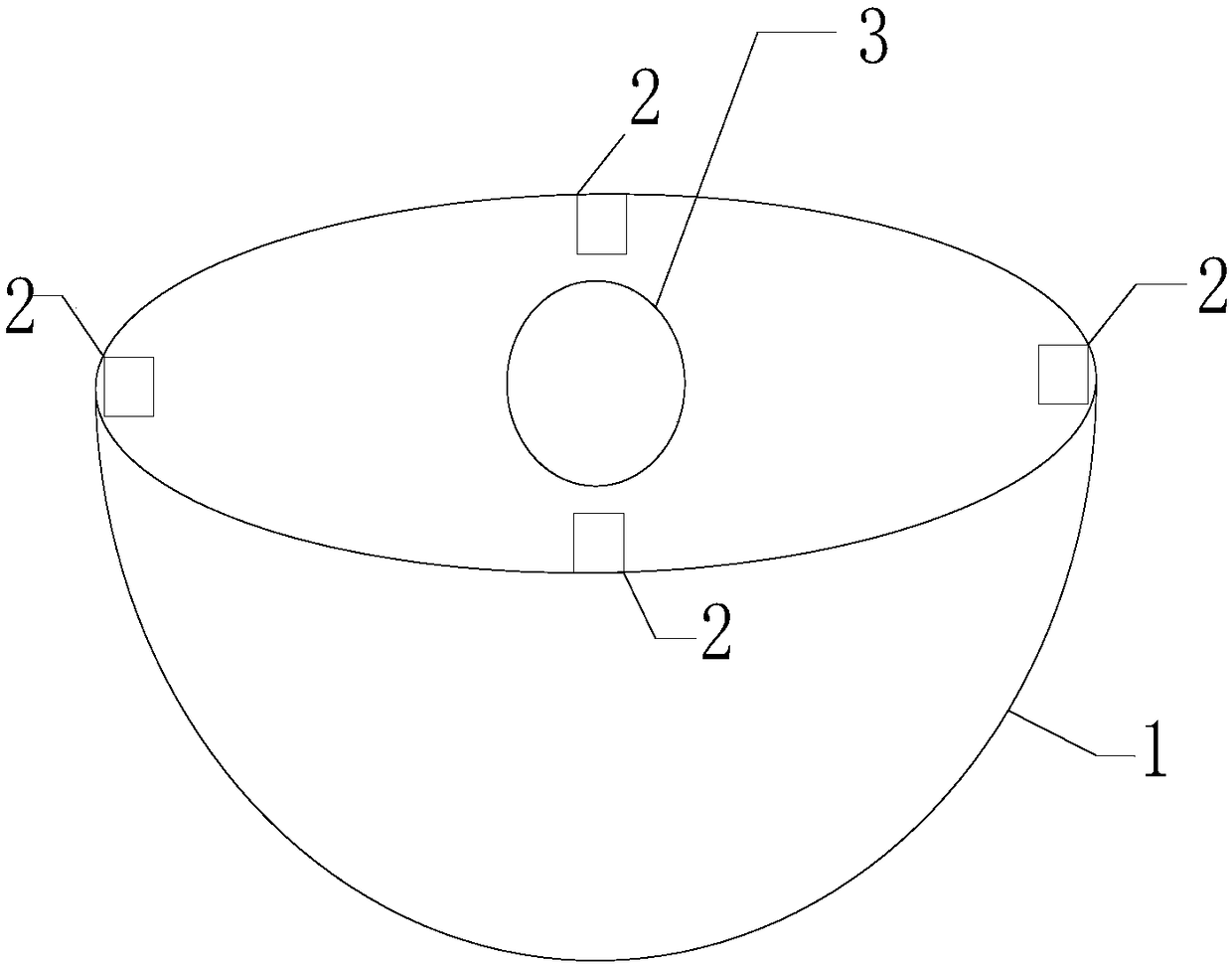

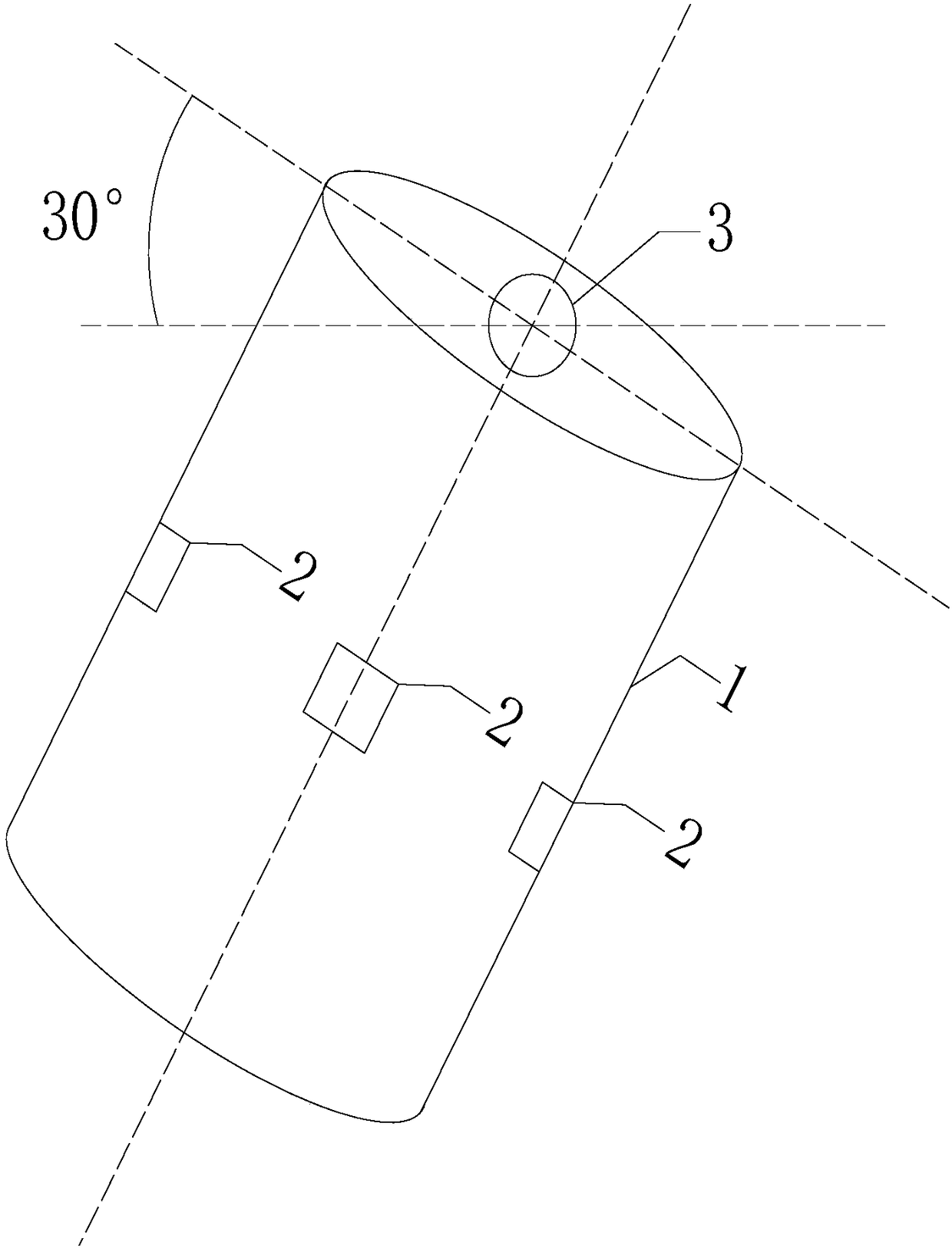

[0034] Embodiments of the present invention provide a bored pile detection device and a bored pile detection method, which can detect the tunnel of the bored pile conveniently, accurately and quickly, and at the same time, the detection device has a simple structure, low cost, Small in size, easy to implement, suitable for popularization and use in various construction sites.

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0036]It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The term "multiple" in the embodiments of the present invention refers to two or more, and in view of this, "multiple" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com