Bolt connection device

A technology for connecting devices and bolts, which is applied in the direction of bolts, connecting components, screws, etc., can solve the problems of increasing labor intensity, increasing the number of assembly parts, reducing assembly safety and reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments. Below in conjunction with accompanying drawing, the present invention is further described.

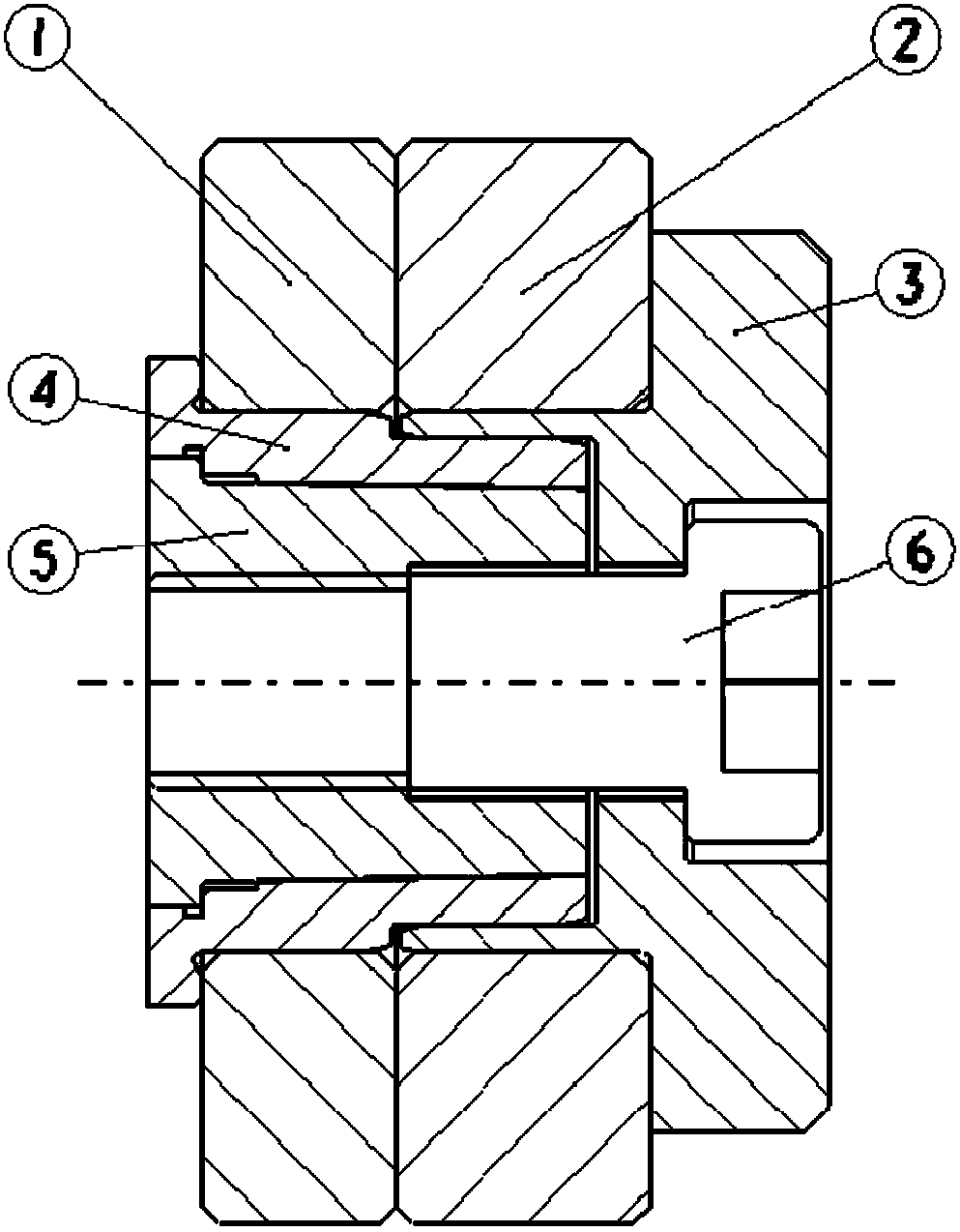

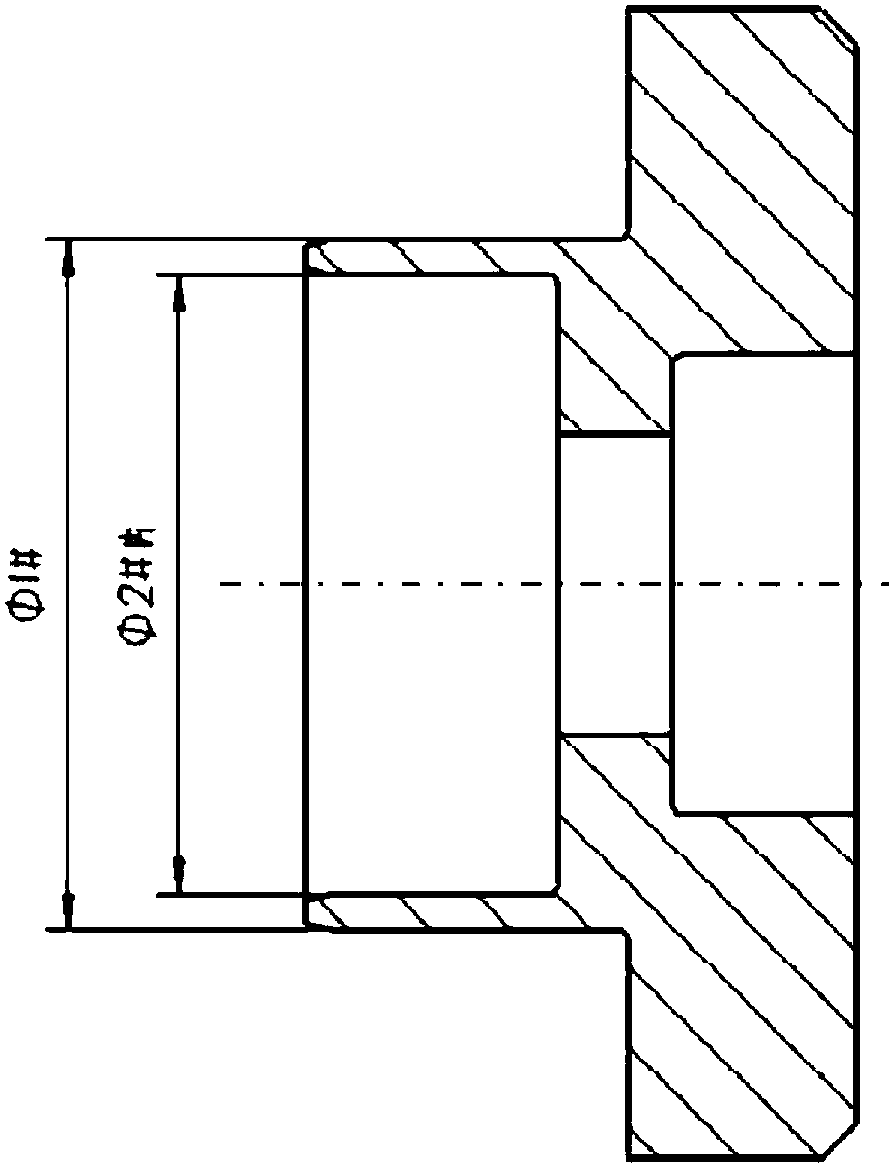

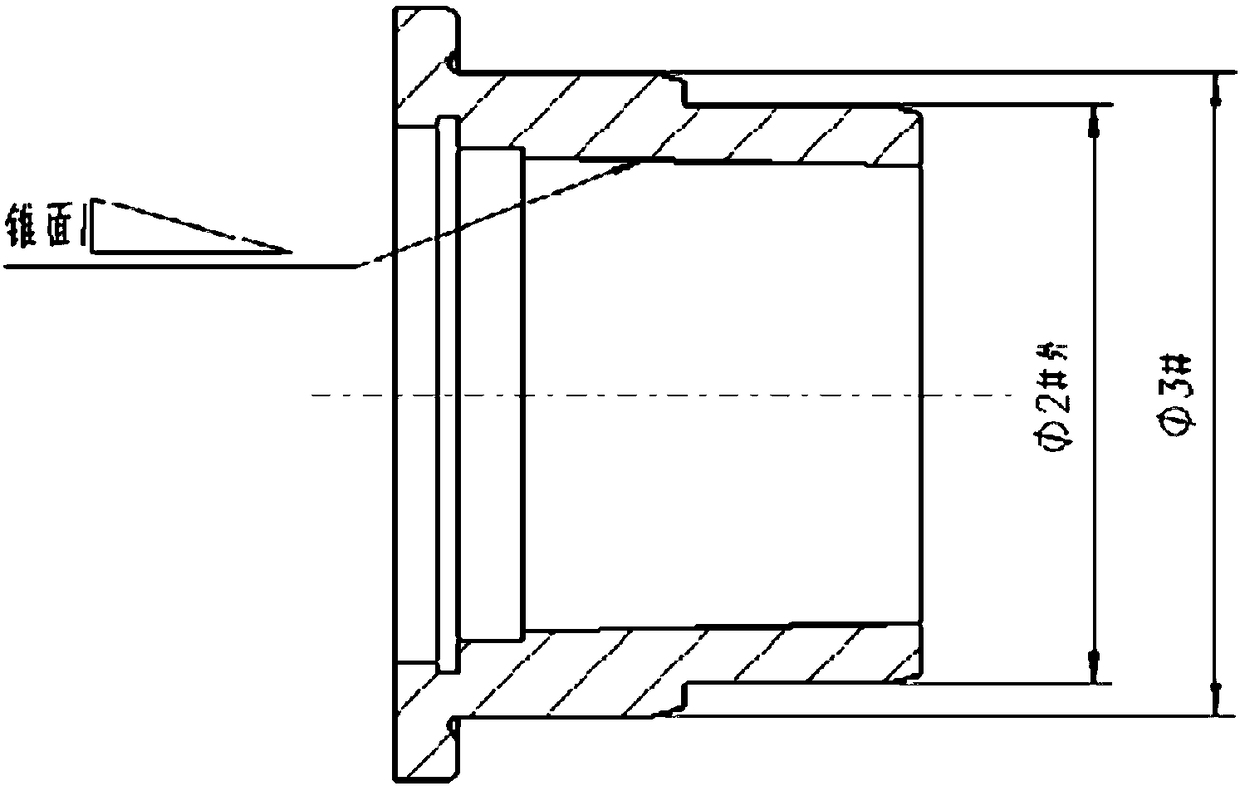

[0015] Such as Figure 1-Figure 4 As shown, the pin sleeve type bolt connection mechanism provided by the present invention uses two pin sleeves with tapered surfaces, which are respectively transition taper sleeve-4 and inner sleeve-5, and the connected parts of transition taper sleeve-4 during initial installation -1 is in contact with the connected part-2 of the inner sleeve-5 first, and the inner sleeve-5 is pulled axially by the axial tension generated during the tightening of the connecting bolt-6, and the inner sleeve-5 is moving towards the outer sleeve-3 Among them, when the interference is generated between the connected part-1 and the connected part-2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com