Heating furnace parameter adjusting optimization analysis method and system thereof

An analysis method and heating furnace technology, applied in control/regulation systems, general control systems, instruments, etc., can solve problems such as uneconomical operation, influence on accuracy, lack of reliability analysis of heating furnace parameters, etc., to achieve strong pertinence and Reliability, the effect of avoiding blind parameter adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

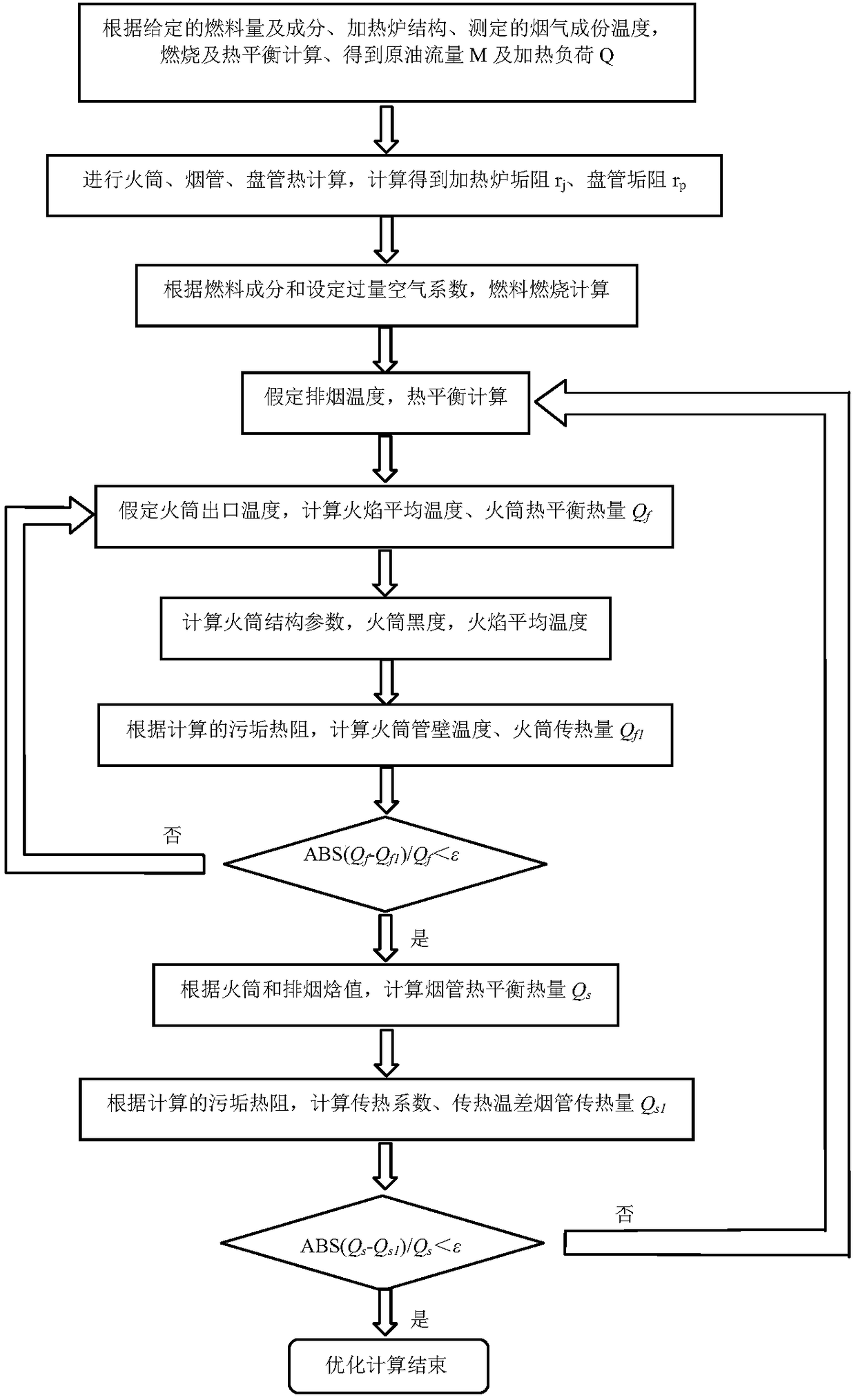

[0049] The embodiment of the present invention provides an analysis method for parameter adjustment optimization of the heating furnace. The analysis method includes: using the fuel parameters and heat balance parameters of the heating furnace measured on site, performing reverse thermal calculation on the heating furnace to obtain the current fouling thermal resistance of the heating furnace , and then based on the calculated fouling thermal resistance of the furnace, an optimization calculation is performed. Among them, the fouling thermal resistance of the heating furnace includes: the scaling resistance of the coil pipe, the scaling resistance of the heating furnace fire tube and the scaling resistance of the flue pipe of the heating furnace. The fuel parameters measured on site include: fuel quantity, fuel composition, and oxygen content in flue gas. The heat balance parameters include oxygen content in flue gas, carbon monoxide content, exhaust gas temperature, furnace bo...

Embodiment 2

[0087] The embodiment of the present invention provides a heating furnace parameter adjustment optimization analysis system, including a flue gas analyzer and a data processing system connected with the flue gas analyzer;

[0088] The flue gas analyzer: a device for collecting flue gas volume, flue gas composition, flue gas temperature, ambient temperature and furnace body surface temperature;

[0089] The data processing system: used for recording and storing various parameters of the heating furnace parameter database, and calling the fuel parameters and heat balance parameters of the heating furnace measured on site, performing reverse thermal calculation on the heating furnace, and obtaining the current dirt of the heating furnace Thermal resistance, and based on the calculated fouling thermal resistance of the heating furnace, an optimization calculation is performed to finally obtain the device with the optimal fuel amount and the optimal excess air coefficient.

[0090]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com